System and method for recycling and efficiently producing flue gas by magnesium desulfurization

A technology of magnesium desulfurization and resource utilization, which is applied in the system field of high-efficiency output of coal-fired flue gas magnesium desulfurization and resource utilization, and can solve problems such as groundwater pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

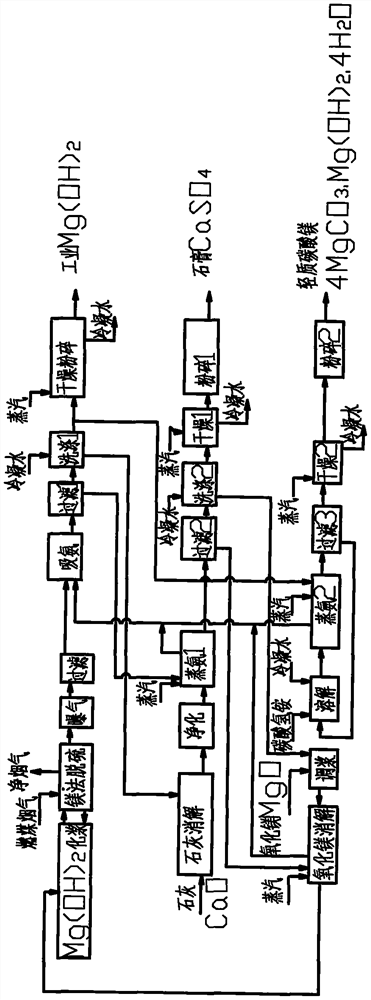

[0086]Example 1:figure 1 It can be seen that the present invention provides the basis of a system of high-efficiency output of flue gas magnesium method desulfurization resource, which is composed of a plurality of chemical cells in accordance with the chemical reaction process, characterized in that:

[0087]P1: MG (OH) in turn by the slurry unit, magnesium oxide resolution unit2Type cell, magnesium method desulfurization unit, aeration unit, filtration unit, an amino unit, filtration 1 unit, washing 1 unit, dry pulverization unit composition industrial magnesium hydroxide Mg (OH)2Product production subsystem;

[0088]P2: Compared with lime mortify unit, purifying unit, evaporase 1 unit, filter 2 unit, dry 1 unit, and pulverize 1 unit to form a gypsum CASO4Product production subsystem;

[0089]P3: Magnesium carbonate 4mgco is composed of a dissolved unit, an evaporated ammonia 2 unit, a filtration of 3 units, a drying 2 unit, and a pulverized 2 unit.3· MG (OH)2· 4h2O product production subs...

Embodiment 2

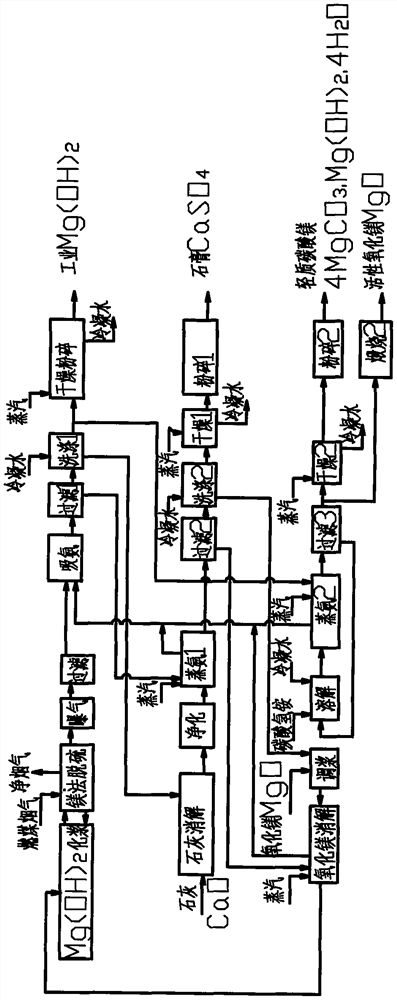

[0091]Example 2:figure 2 It can be seen that the present invention provides an optimization embodiment of a system for efficient output of flue gas magnesium method desulfurization resource, and is associated with a plurality of chemical cells in accordance with the chemical reaction process, characterized in that:

[0092]P1: MG (OH) in turn by the slurry unit, magnesium oxide resolution unit2Type cell, magnesium method desulfurization unit, aeration unit, filtration unit, an amino unit, filtration 1 unit, washing 1 unit, dry pulverization unit composition industrial magnesium hydroxide Mg (OH)2Product production subsystem;

[0093]P2: Compared with lime mortify unit, purifying unit, evaporase 1 unit, filter 2 unit, dry 1 unit, and pulverize 1 unit to form a gypsum CASO4Product production subsystem;

[0094]P3: Light carbonate 4mgco composed of dissolved units, evaporase 2 units, filtration 3 units, dried 2 units, pulverized 2 units, calcination 2 units3· MG (OH)2· 4h2O product production s...

Embodiment 3

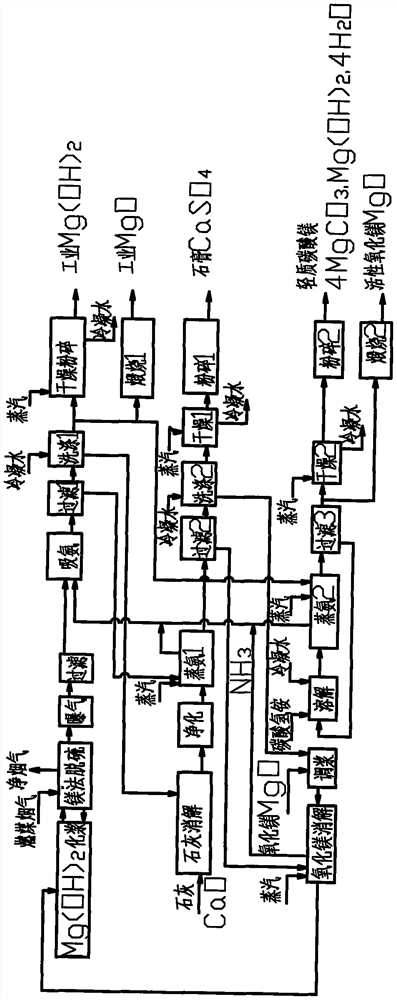

[0096]Example 3: Referenceimage 3As shown, the present invention provides an optimization embodiment of a method of high efficiency of flue gas magnesium method desulfurization resource-efficient output, and a plurality of chemical units are sequentially associated in accordance with the chemical reaction process, characterized in that:

[0097]Step S1: Using pure water modulfurizing solution MG (OH)2, Washing solution 2 modulated desulfurization Mg (OH) for washing liquid 2 modulated desulfurization of calcium sulfate filter material with condensed water2Slurry and desulfurization - adding an appropriate amount of light burning powder and washing liquid 2 of the two units, stirring the ash as a pulp; adding the filtration of the filtration 2 unit in a sealed magnesium oxide encapsulating unit (equivalent to magnesium oxide) 2, and pump the slurry of the gel units into the slurry into Mg (OH)2Slurry, pass steam heating The ammonia residue in the filtrate 2 (in the filtrate 2 with ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com