Hydrophobic polyolefin composition and preparation method thereof

A composition and polyolefin technology, applied in the field of modified plastics and their preparation, can solve problems such as loss of due effect, separation of hydrophobic components, attenuation of mechanical properties, etc., and achieve excellent hydrophobic performance, improved hydrophobic performance, and good rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

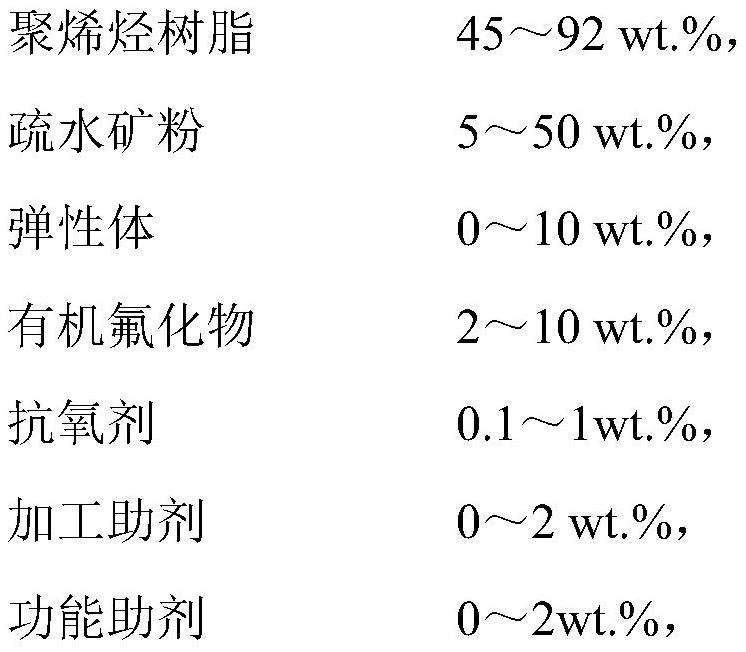

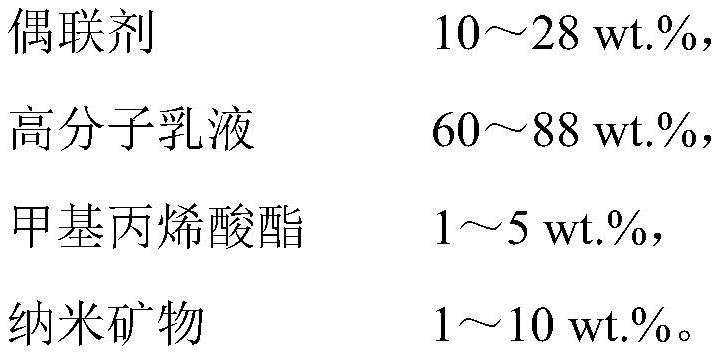

[0056] Hydrophobic polyolefin composition, by weight percentage, its mineral powder treatment liquid composition is as follows:

[0057]

[0058] The preparation method of the emulsion is as follows: firstly add the monoalkoxy pyrophosphate type titanate coupling agent, the polypropylene wax emulsion grafted with maleic anhydride and methacrylate into the strong shear emulsification equipment, stir at a low speed of 100rpm Evenly, then add 1.0wt.% nano-calcium carbonate in proportion, first shear at a low speed of 100rpm, then slowly increase the speed to 3000rpm, stir at a high speed for 10 minutes, then stop slowly, and wait for standing without stratification, Then add 1.0wt.% nano-calcium carbonate, cut according to the method of the previous step, and wait for standing without delamination to complete the preparation of the treatment solution.

[0059] Mineral powder treatment method: first immerse the mica in the treatment solution twice the mass, and stir at a low sp...

Embodiment 2

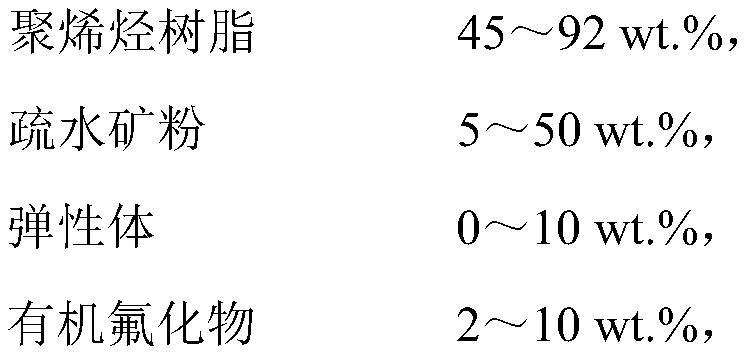

[0064] Hydrophobic polyolefin composition, its mineral powder treatment fluid composition is as follows:

[0065]

[0066] The preparation method of the emulsion is as follows: first, add the chelating titanate coupling agent, vinyl silane coupling agent, MMA-BA-AA emulsion and methacrylic acid into the strong shear emulsification equipment, and stir evenly at a low speed of 100rpm. Then add 1.0wt.% nano-silica in proportion, first shear at a low speed of 100rpm, then slowly increase the speed to 3000rpm, stir at high speed for 10 minutes, then stop slowly, wait until it is not stratified, and then add 1.0wt.% nano-calcium carbonate, cut according to the method of the previous step, after standing still without delamination, then add 1.0wt.% nano-calcium carbonate, cut according to the method of the previous step, after standing without delamination, complete the treatment liquid preparation.

[0067] Mineral powder treatment method: first impregnate calcium carbonate in t...

Embodiment 3

[0072] Hydrophobic polyolefin composition, its mineral powder treatment fluid composition is as follows:

[0073]

[0074] The preparation method of the emulsion is as follows: First, add epoxy silane coupling agent, polyethylene wax emulsion grafted with maleic anhydride and n-butyl methacrylate into the emulsification equipment with strong shear, stir evenly at a low speed of 100rpm, and then press Add 1.0wt.% nano-titanium dioxide in proportion, first shear at a low speed of 100rpm, then slowly increase the speed to 3000rpm, stir at a high speed for 10 minutes, then stop slowly, wait for standing without stratification, and then add 1.0wt.% Nano-titanium dioxide, cut according to the previous step, after standing still without delamination, then add 1.0wt.% nano-titanium dioxide, in this order, until all the nano-mineral powder is added, and the preparation of the treatment solution is completed.

[0075] Mineral powder treatment method: first immerse the talc powder in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com