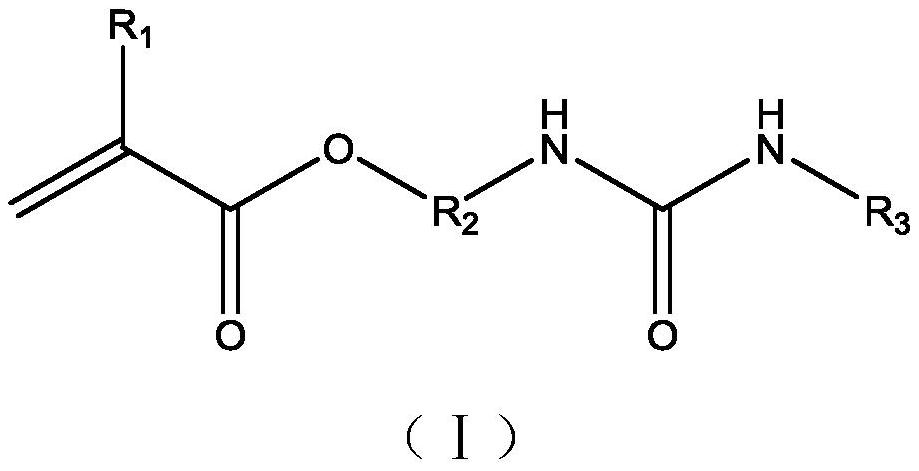

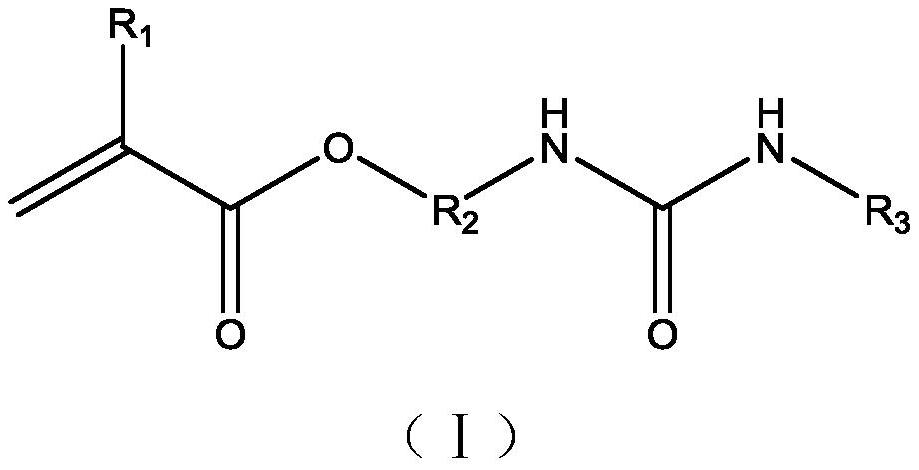

Acrylate emulsion as well as preparation method and application thereof

A technology of acrylate and acrylic monomers, which is applied in coatings and other directions, can solve problems such as low crosslinking efficiency and crosslinking agent residue, and achieve the effects of improving compatibility, increasing hardness, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

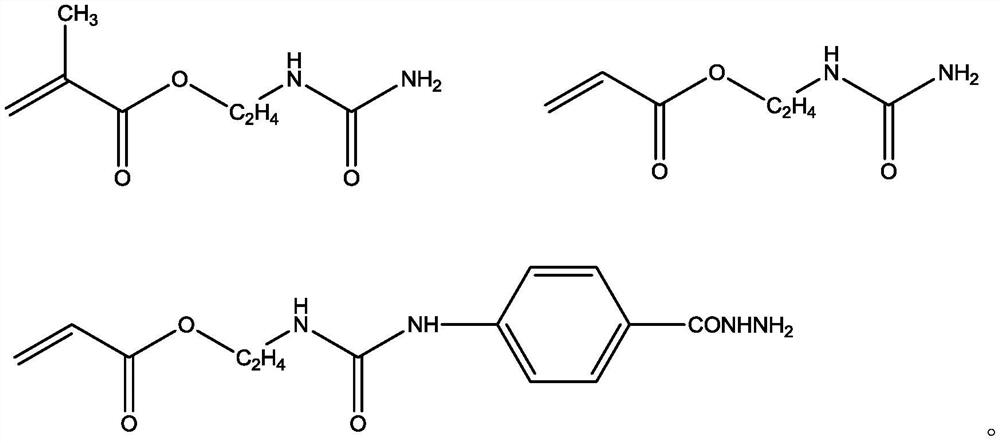

[0088] 1) Preparation of pre-emulsion A: Under normal temperature, 3 g of sodium dodecyl sulfonate and 135.34 g of deionized water were added to the prematocity tank with a monomer meter, stirrer, and dissolved After the addition of 100 g of styrene and 100 g of methyl methacrylate and 1 g of double acetone acrylamide were added, stirred for 20 min;

[0089] 2) Preparation of pre-emulsion B: Under normal temperature, 1 g of sodium dodecyl sulfonate and 68.34 g of deionized water were added to pre-emulsion with monomer meter, stirrer, and stirred well After the addition of 50 g of 2-methylstyrene and 50 g of methyl methacrylate and 1 g of 2- (ahydrazide) ethylmethyl methacrylic acid, thoroughly stirred for 20 min;

[0090] 3) Pretreatment of pre-emulsion A obtained from step 1) and heating temperature increases to 65 ° C, 0.5 g of potassium sulfate and 20 g of a mixed solution of 20 g of water, and the dropwise time is 2 h, and the addition is 0.5h after the end of the end. , Then ...

Embodiment 2

[0094] 1) Preparation of pre-emulsion A: Under normal temperature, 3 g of sodium dodecyl benzene sulfonate and 1 g of alkyl polyoxyethylene ether LCN407 were added to pre-emulsion with monomer meter and agitator. After 500 g of deionized water, after stirring dissolved, 15 g of 2-methylstyrene and 227 g of methyl methacrylate and 8 g of double acetone acrylamide were sufficiently stirred for 30 min;

[0095] 2) Preparation of pre-emulsion B: Under normal temperature, 1 g of sodium dodecyl sulfonate and 1 g of alkyl polyoxyethylene ether LCN407 were added to pre-emulsion with monomer meter and agitator. After 248 g of deionized water, after stirring dissolved, 60 g of 2-methylstyrene and 56 g of acrylate and 8 g of 2- (ahydrazide) ethyl acrylic acid were added, and stirred for 30 min;

[0096] 3) Step 1) The premixed liquid A obtained by the resulting temperature above 90 ° C, starting the mixed solution of 2.4 g of ammonium sulfate and 24 g of water, and the dropwater is 3 h, and ...

Embodiment 3

[0100] 1) Preparation of pre-emulsion A: Under normal temperature, 6 g of 6 g of sodium dodecyl sulfonate and 500 g of deionized water are added to the prematurated tank with a monomer meter, and the mixture is fully stirred. To sequentially add 227 g of 4-methylstyrene and 15 g of butyl acrylate and 2 g of double acetone acrylamide, thoroughly stirred for 25 min;

[0101] 2) Preparation of pre-emulsion B: Under normal temperature, 9 g of sodium dodecyl sulfonate and 200 g of deionized water are added to pre-emulsion with a monomer tank, stirrer, and thoroughly stirred and dissolved. , 56 g of 4-methylstyrene and 60 g of methacrylate and 2 g of 2- (ahydrazide) ethyl acrylic acid were combined, stirred for 25 min;

[0102] 3) When the pre-emulsion A obtained from step 1) is heated to 80 ° C, and the mixed solution of 0.5 g of ammonium sulfate and 20 g of water is started to initiate polymerization, the dropwise time is 2.5 h, and after the end of the end of the end of 0.8h, then ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com