Preparation method of high-frequency high-Q capacitor

A capacitor and high-frequency technology, applied in the field of high-frequency high-Q capacitor preparation, can solve the problems of high-frequency, high-Q capacitors with small capacity, low Q value, and inability to meet the requirements of mobile communication equipment, and achieves low equivalent series connection. Effects of resistance, high Q, high self-resonant frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] A method for preparing a high-frequency high-Q capacitor, comprising the following steps:

[0035]Step 1. Preparation of highly active composite powder with "shell-core" structure, the specific steps are as follows:

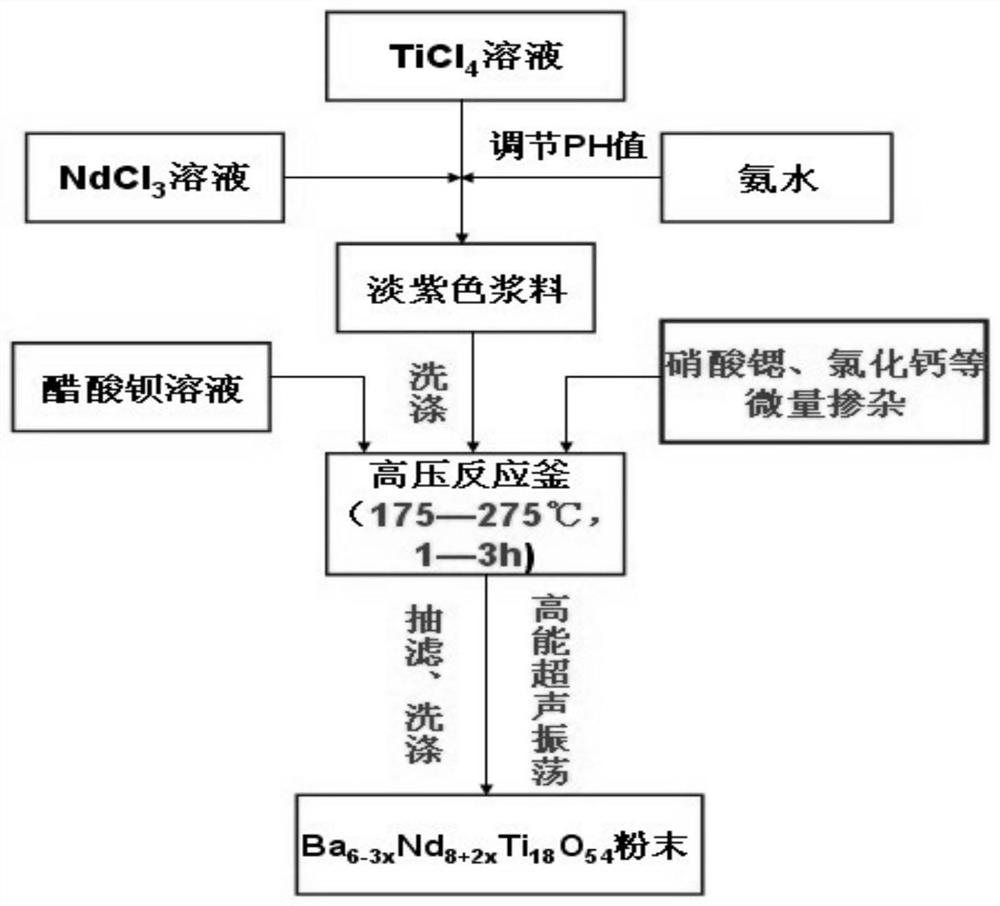

[0036] e. First, prepare Ba6-3xNd8+2xTi18O54 powder by hydrothermal method, put titanium tetrachloride, barium acetate, neodymium chloride and doping element solution in an autoclave, and carry out high pressure at 175-275°C

[0037] f. Hydrothermal reaction to obtain Ba6-3xNd8+2xTi18O54 high-activity powder uniformly doped with trace elements, for future use;

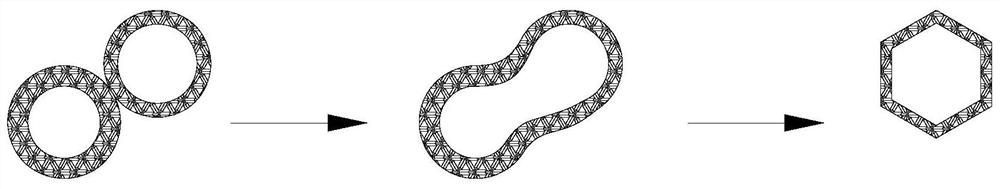

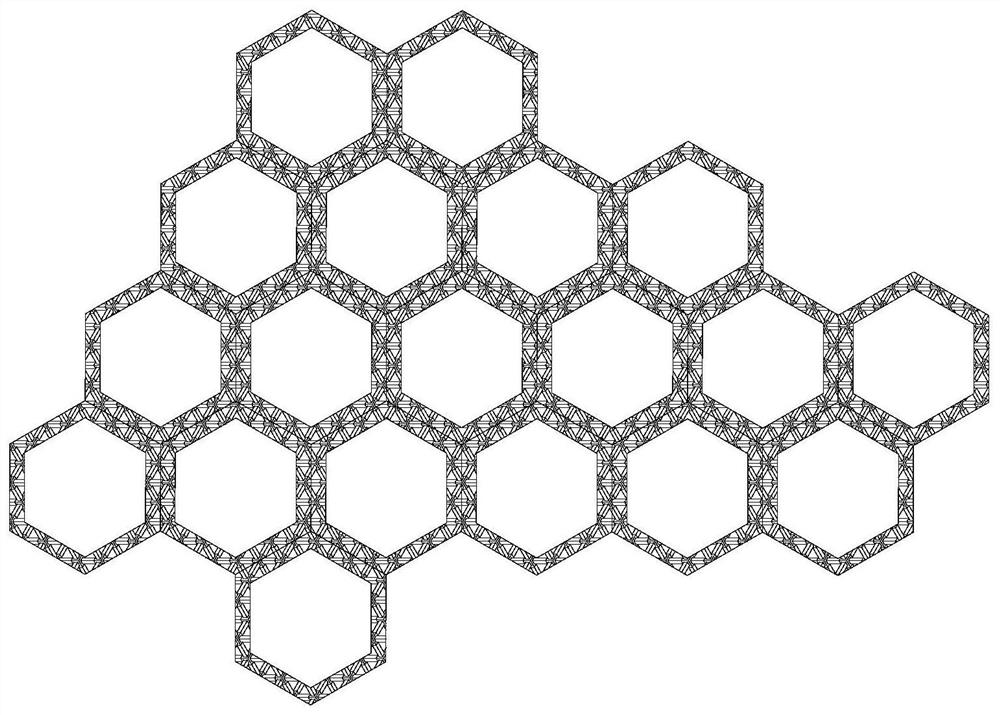

[0038] c. It is planned to add ultrasonic vibration treatment to the powder obtained in the specific step a, so that the agglomeration effect of the powder is reduced, and the dispersibility and activity are further improved. The Ba6-3xNd8+2xTi18O54 powder preparation process flow chart is as follows figure 1 shown. Then, mix the Ba6-3xNd8+2xTi18O54 powder prepared in the specific step b with Mg(...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com