Preparation method of palladium in-situ modified copper-cobalt doped cerium dioxide nanospheres

A ceria, in-situ modification technology, applied in the field of nanomaterials, can solve the problem that high-selectivity electrochemical biosensors cannot be fully satisfied, and achieve the effect of simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preparation method for palladium in-situ modification of copper-cobalt-doped ceria nanospheres is characterized in that it comprises the following steps:

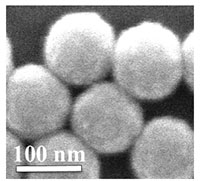

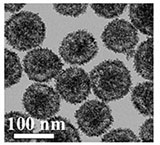

[0018] (1) Preparation of copper-cobalt double-doped ceria nanospheres: Weigh 500 mg cerium nitrate and 200 mg polyvinylpyrrolidone and dissolve them in 14 mL ethylene glycol solution, stir at a constant speed for 30 min at room temperature, and weigh 160 mg respectively Dissolve copper chloride and 229.44 mg cobalt chloride in 8 mL of ultrapure water and stir to fully dissolve, pipette 0.5 mL of copper chloride and cobalt chloride solution into the ethylene glycol solution of cerium nitrate And continue to stir. After the mixed solution is stirred evenly, transfer the reaction solution to a 20 mL polytetrafluoroethylene-lined autoclave that has been washed and dried, and put it in a drying oven at 160 °C for 8 h at high temperature to ensure After the reaction was complete, it was naturally cooled to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com