Supercapacitor electrode material, preparation method thereof and supercapacitor

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems that the electrochemical performance of electrode materials needs to be further improved, cannot be mass-produced, and has few active sites. Improve electrochemical performance, enrich active sites, and improve the effect of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

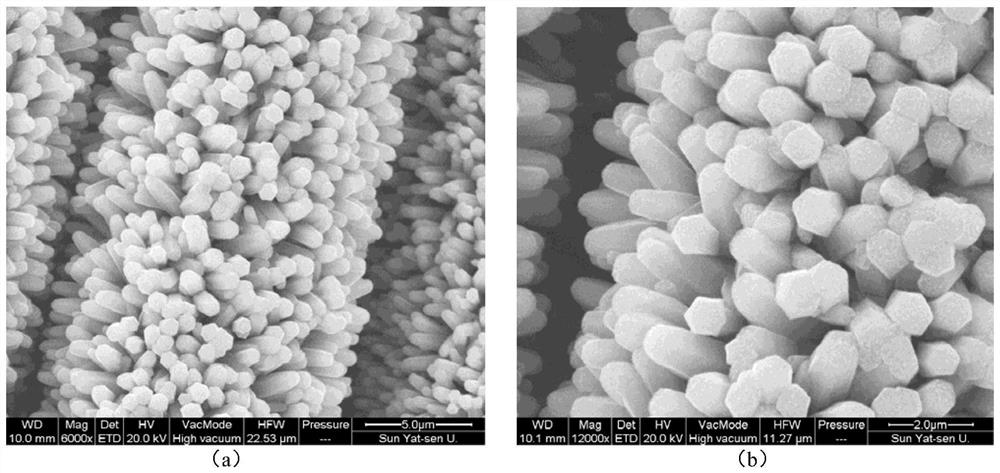

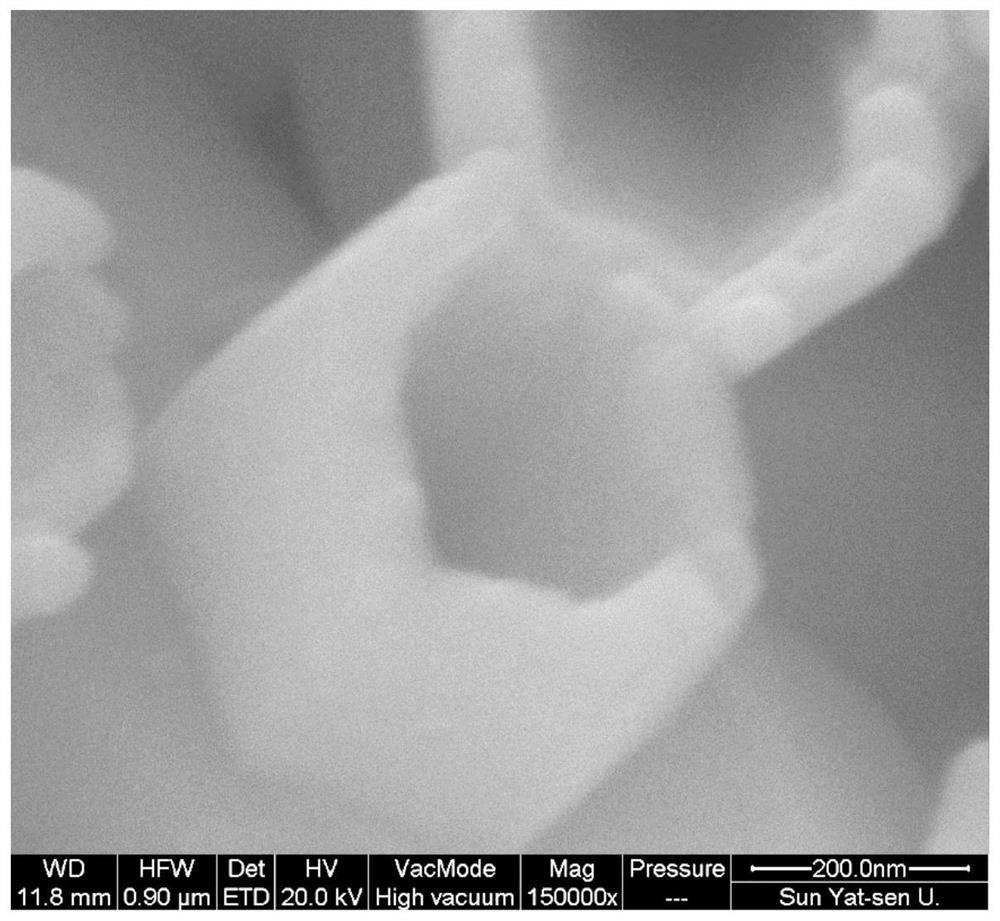

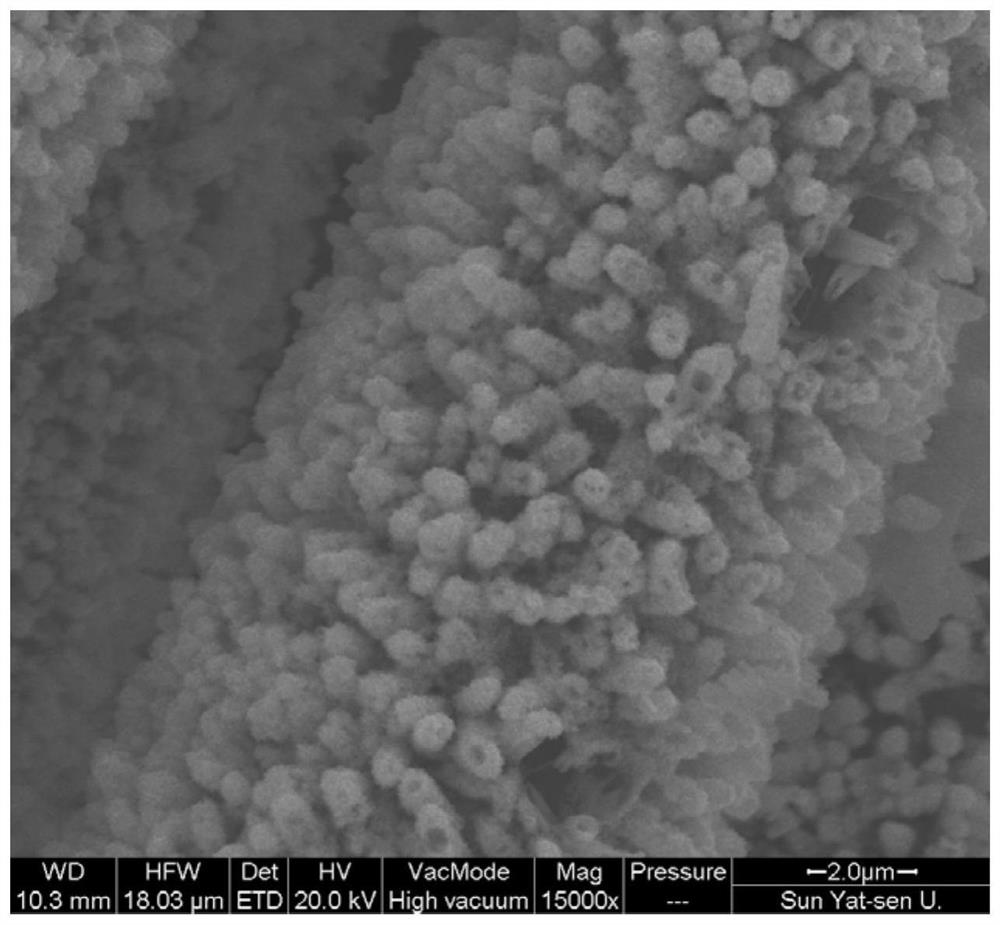

Image

Examples

Embodiment 1

[0042] A kind of supercapacitor electrode material, its preparation method comprises the following steps:

[0043] S1. Sonicate the flexible carbon fiber cloth in ethanol at room temperature for 30min, then soak it in concentrated nitric acid with a mass fraction of about 68% for 1h, then sonicate and rinse in ultrapure water for 30min, and finally wash it with ultrapure water, and then Dry at 60°C;

[0044] S2, using zinc nitrate and ammonium nitrate to prepare an electroplating solution, so that the electroplating solution contains 0.01M zinc ions and 0.04M ammonium ions; then the flexible carbon fiber cloth treated in step S1 is used as a cathode, and connected to the circuit together with the anode carbon rod, Then insert the electrode into the electroplating solution, control the temperature of the electroplating solution to 70°C, and set the current density at 0.8mA / cm 2 Electrodeposition was carried out for 90 minutes; after the electrodeposition was completed, the dep...

Embodiment 2

[0049] A kind of supercapacitor electrode material, its preparation method comprises the following steps:

[0050] S1. Sonicate the flexible carbon fiber cloth in ethanol at room temperature for 30min, then soak it in concentrated nitric acid with a mass fraction of about 68% for 1h, then sonicate and rinse in ultrapure water for 30min, and finally wash it with ultrapure water, and then Dry at 60°C;

[0051] S2, using zinc nitrate and ammonium nitrate to prepare an electroplating solution, so that the electroplating solution contains 0.01M zinc ions and 0.04M ammonium ions; then the flexible carbon fiber cloth treated in step S1 is used as a cathode, and connected to the circuit together with the anode carbon rod, Then insert the electrode into the electroplating solution, control the temperature of the electroplating solution to 70°C, and set the current density at 0.8mA / cm 2 Electrodeposition was carried out for 90 minutes; after the electrodeposition was completed, the dep...

Embodiment 3

[0056] A kind of supercapacitor electrode material, its preparation method comprises the following steps:

[0057] S1. Sonicate the flexible carbon fiber cloth in ethanol at room temperature for 30min, then soak it in concentrated nitric acid with a mass fraction of about 68% for 1h, then sonicate and rinse in ultrapure water for 30min, and finally wash it with ultrapure water, and then Dry at 60°C;

[0058] S2, using zinc nitrate and ammonium nitrate to prepare an electroplating solution, so that the electroplating solution contains 0.01M zinc ions and 0.04M ammonium ions; then the flexible carbon fiber cloth treated in step S1 is used as a cathode, and connected to the circuit together with the anode carbon rod, Then insert the electrode into the electroplating solution, control the temperature of the electroplating solution to 70°C, and set the current density at 0.8mA / cm 2 Electrodeposition was carried out for 90 minutes; after the electrodeposition was completed, the dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com