Polyimide film and flexible display panel including the same

A technology of polyimide base film and covering film, which is applied in the direction of identification devices, instruments, coatings, etc., and can solve problems such as eye fatigue and visibility degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] The preparation of the oligomer may include reacting a fluoro-based aromatic diamine with an aromatic diacid chloride in a reactor, and purifying and drying the obtained oligomer. In this case, the fluorine-based aromatic diamine may be added at a molar ratio of 1.01 to 2 relative to the aromatic diacid chloride, and an amine-terminated polyamide oligomer monomer may be prepared. The molecular weight of the oligomer monomer is not particularly limited, but, for example, when the weight average molecular weight is in the range of 1000 g / mol to 3000 g / mol, more excellent physical properties can be obtained.

[0070] In addition, in order to introduce an amide structure, it is preferable to use an aromatic carbonyl halide monomer such as terephthaloyl chloride or isophthaloyl chloride instead of terephthalate (or phthalate) or terephthalate Dicarboxylic acid (or phthalic acid) itself. Chlorine appears to affect the physical properties of the membrane, but this is unclear....

preparation example 1

[0154] [Preparation Example 1] Preparation of a composition for forming a hard coat layer

[0155]2-(3,4-Epoxycyclohexyl)ethyltrimethoxysilane (ECTMS, TCI Co., Ltd.) and water were mixed in a ratio of 24.64g:2.70g (0.1mol:0.15mol) to prepare a reaction solution, and The reaction solution was placed in a 250 mL two-necked flask. 0.1 mL of tetramethylammonium hydroxide catalyst (Sigma-Aldrich) and 100 mL of tetrahydrofuran (Sigma-Aldrich) were added to the above mixture, and stirred at 25° C. for 36 hours. Afterwards, layer separation was performed, the product layer was extracted with dichloromethane (Sigma-Aldrich), water was removed from the extract using magnesium sulfate (Sigma-Aldrich), and the solvent was removed by drying under vacuum to obtain epoxy silicon Oxygenated resins. As a result of measurement using gel permeation chromatography (GPC), the epoxysiloxane-based resin had a weight average molecular weight of 2500 g / mol.

[0156] The 30g epoxysiloxane-based resi...

Embodiment 1

[0158]

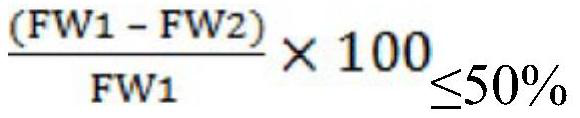

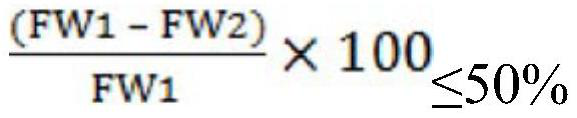

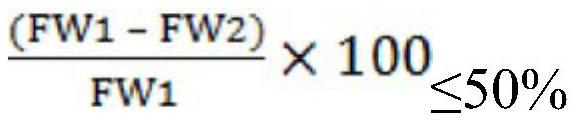

[0159] Add terephthaloyl chloride (TPC) and 2,2'-bis(trifluoromethyl)-benzidine (TFMB) in the state of a mixed solution of dichloromethane and pyridine into the reactor, and Stir at 25°C for 2 hours. At this time, the molar ratio of TPC:TFMB was set to 300:400, and the solid content was adjusted to 10% by weight. Thereafter, the reactant was precipitated in an excess amount of methanol, and the solid content obtained by filtration was vacuum-dried at 50° C. for 6 hours or more to obtain an oligomer. The molecular weight (FW) of the prepared oligomer was 1670 g / mol.

[0160] N,N-dimethylacetamide (DMAc), 100 mol of oligomer and 28.6 mol of 2,2'-bis(trifluoromethyl)benzidine (TFMB) as solvent were added to the reactor and fully Stir. After confirming that solid raw material dissolves completely, fumed silica (surface area 95m 2 / g, <1 μm) was added to DMAc in an amount of 1000 ppm relative to solids and dispersed using ultrasonic waves. Add 64.3 mol of cyclobutan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com