Preparation method of polydopamine/polylactic acid/nano-copper composite fiber membrane with photo-thermal/copper synergistic antibacterial function

A technology of composite fibrous membrane and polylactic acid fiber, which can be applied in fiber type, fiber treatment, biochemical fiber treatment, etc., can solve the problems of increasing surgical risk and developing drug resistance, and achieves the promotion of osteogenesis and angiogenesis, and promotes bone tissue repair. , rapid and long-lasting anti-bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

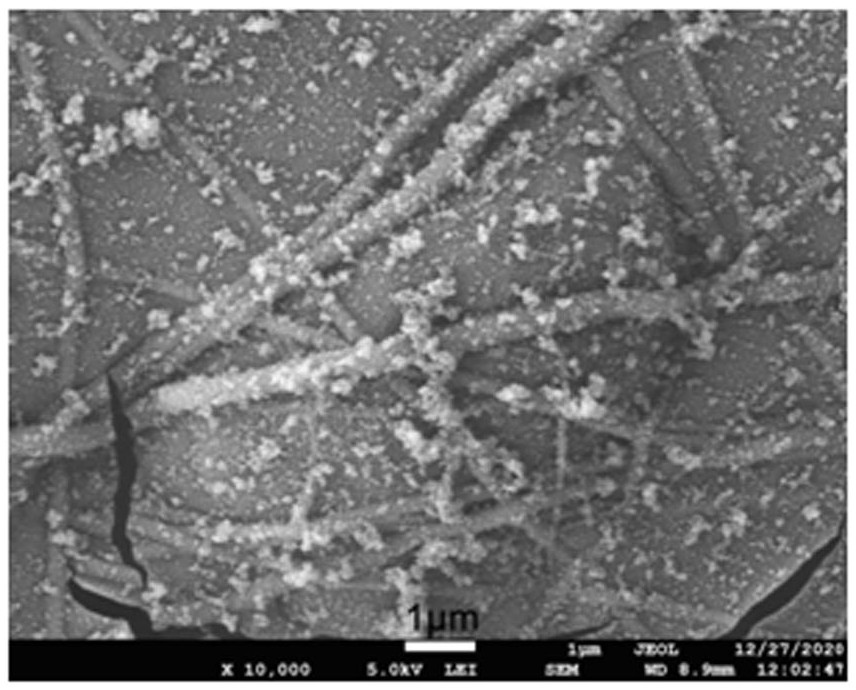

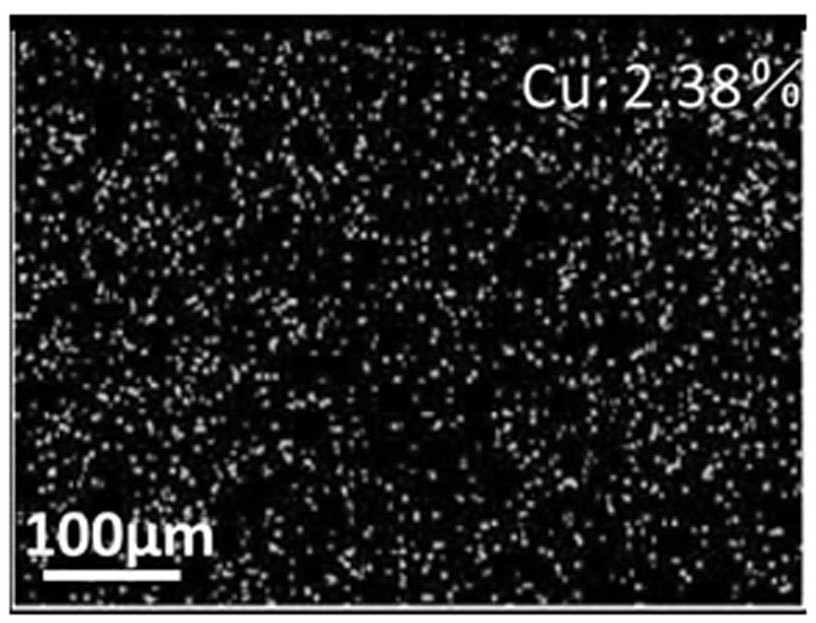

[0033] The invention provides a method for preparing a polydopamine / polylactic acid / nano-copper composite fiber membrane with photothermal / copper synergistic antibacterial function, comprising the following steps:

[0034] (1) Dissolve 1.44 g of polylactic acid in 9 mL of trifluoroethanol, and use mechanical stirring at a speed of 1300r / min for 16 h to completely dissolve it to obtain a uniform electrospinning solution of polylactic acid;

[0035] (2) Electrospinning was carried out with the polylactic acid electrospinning solution obtained in step (1) as the raw material. The parameters were high-voltage electrostatic field voltage 15kv, spinning receiving distance 13 cm, and syringe advancing speed 3 mL / h. Polylactic acid fiber membrane on the surface of the foil collector;

[0036] (3) The polylactic acid fiber membrane obtained in step (2) was vacuum-dried at 70°C for 72 h to completely remove the residual solvent, and then the obtained fiber membrane was cut into 2 cm×2 c...

Embodiment 2

[0043] The invention provides a method for preparing a polydopamine / polylactic acid / nano-copper composite fiber membrane with photothermal / copper synergistic antibacterial function, comprising the following steps:

[0044] (1) Dissolve 1.81 g of polylactic acid in 15 mL of dimethyl sulfoxide, and use mechanical stirring at a speed of 1000r / min for 20 h to completely dissolve it to obtain a uniform electrospinning solution of polylactic acid;

[0045] (2) Electrospinning was carried out using the polylactic acid electrospinning solution obtained in step (1) as a raw material. The parameters were high-voltage electrostatic field voltage 12kv, spinning receiving distance 15 cm, and syringe advancing speed 2 mL / h. Polylactic acid fiber membrane on the surface of the foil collector;

[0046] (3) The polylactic acid fiber membrane obtained in step (2) was vacuum-dried at 80°C for 96 h to completely remove the residual solvent, and then the obtained fiber membrane was cut into 4 cm×4...

Embodiment 3

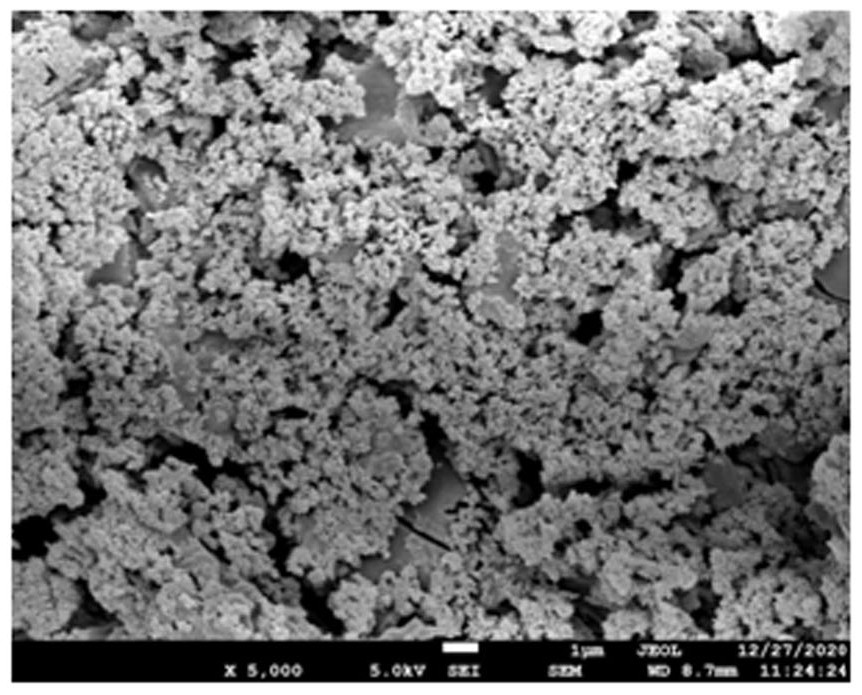

[0052] The invention provides a method for preparing a polydopamine / polylactic acid / nano-copper composite fiber membrane with photothermal / copper synergistic antibacterial function, comprising the following steps:

[0053] (1) Dissolve 6.56 g of polylactic acid in 36 mL of an equal proportion mixed solution of hexafluoroisopropanol and chloroform, and use a mechanical stirrer at a speed of 1500r / min for 12 h to completely dissolve it to obtain a uniform electrospun polylactic acid silk solution;

[0054] (2) Electrospinning was carried out with the polylactic acid electrospinning solution obtained in step (1) as raw material. The parameters were high-voltage electrostatic field voltage 18kv, spinning receiving distance 14 cm, and syringe advancing speed 4 mL / h. Polylactic acid fiber membrane on the surface of the foil collector;

[0055] (3) The polylactic acid fiber membrane obtained in step (2) was vacuum-dried at 80°C for 96 h to completely remove the residual solvent, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com