A kind of tissue adhesive and its preparation method and application

A tissue adhesive and cross-linking agent technology, used in applications, surgical adhesives, pharmaceutical formulations, etc., can solve the problem of inability to fully meet clinical needs, poor mechanical properties, and super-strong hydrogels lack of cell affinity and tissue. Adhesion and other issues, to achieve the effect of good wide applicability, good biocompatibility, and high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 2 g of gelatin (bovine origin) was dissolved in 20 mL of deionized water at 60°C to obtain a 10 wt / vol% gelatin solution. After the pH value was adjusted to 8.5 with sodium hydroxide solution, 0.2 g / mL aqueous tannic acid solution was added dropwise to the gelatin solution using a syringe (a total of 1 mL of tannic acid aqueous solution was used), and after it was completely dissolved and uniformly mixed ( The time was controlled at 0.5h), and the pH of the solution was adjusted to 7.1 with hydrochloric acid solution, which was recorded as solution I.

[0064] 0.04 g of genipin was dissolved in 1 mL of 70% ethanol solution at room temperature. Subsequently, the solution I and the genipin solution (volume ratio of 1:1) were poured into a double-barrel syringe, extruded, and subjected to in-situ cross-linking reaction at room temperature (25° C.) for 10 min to obtain high-strength adhesion. Strong tissue adhesive.

Embodiment 2

[0069] 1.5 g of gelatin (fish source) was dissolved in 20 mL of deionized water at 40°C to give a 7.5 wt / vol % gelatin solution. After adjusting the pH value to 8.1 with sodium hydroxide solution, use a syringe to add 0.5 g / mL gallic acid aqueous solution dropwise to the gelatin solution (a total of 1 mL of gallic acid aqueous solution is used), and after it is completely dissolved and mixed evenly (time control) At 0.75h), the pH of the solution was adjusted to 7.1 with a hydrochloric acid solution, which was designated as solution I.

[0070] 0.08 g of genipin was dissolved in 2 mL of 75% ethanol solution at room temperature. Subsequently, solution I and genipin solution (volume ratio of 3:1) were poured into a double-barrel syringe, extruded, and subjected to in-situ cross-linking reaction at room temperature (20° C.) for 15 min to obtain high-strength adhesion. Strong tissue adhesive.

[0071] Use a double-barrel syringe to extrude solution I and genipin solution (volume...

Embodiment 3

[0075] 1.5 g of gelatin (porcine source) was dissolved in 30 mL of deionized water at 40° C. to obtain a 5 wt / vol % gelatin solution. After the pH value was adjusted to 8.8 with sodium hydroxide solution, 0.8 g / mL tannic acid aqueous solution was added dropwise to the gelatin solution using a syringe (a total of 1 mL of tannic acid aqueous solution was used), and the pH of the solution was adjusted to 7.1 with hydrochloric acid solution , denoted as solution I.

[0076] 0.1 g of genipin was dissolved in 1 mL of 75% ethanol solution at room temperature. Subsequently, solution I and genipin solution (volume ratio of 1.5:1) were poured into a double-barrel syringe, extruded, and subjected to in-situ cross-linking reaction at room temperature (30° C.) for 20 min to obtain high-strength adhesion. Strong tissue adhesive.

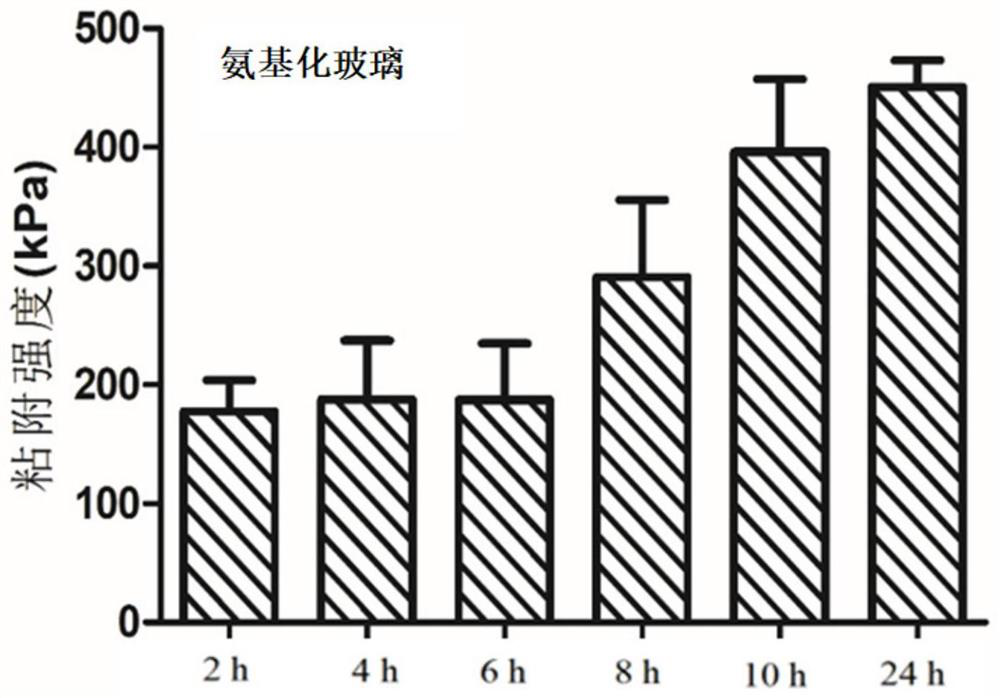

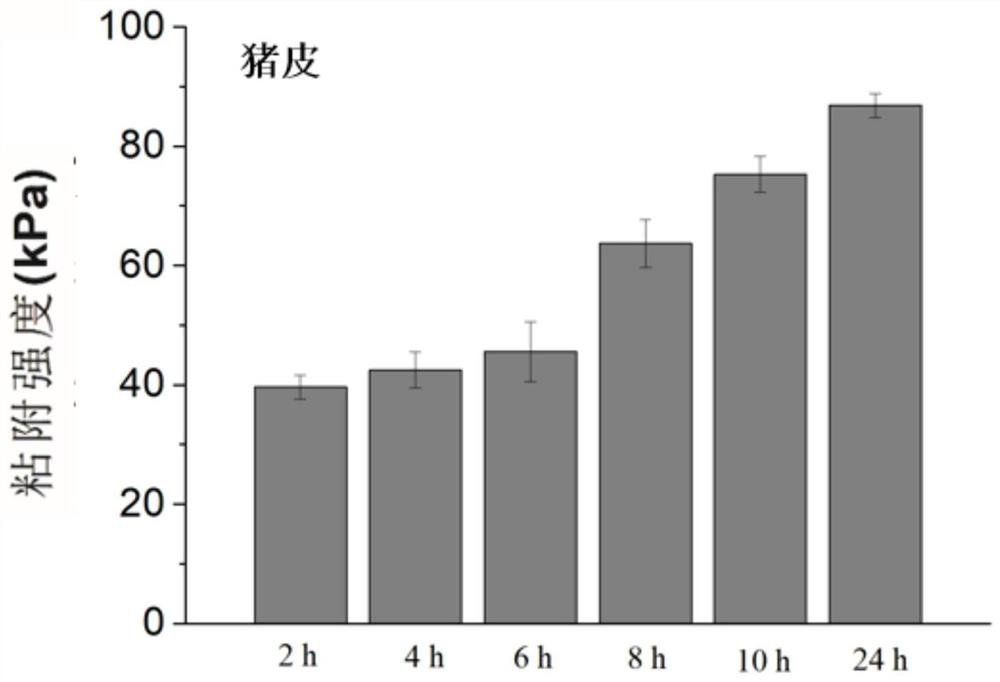

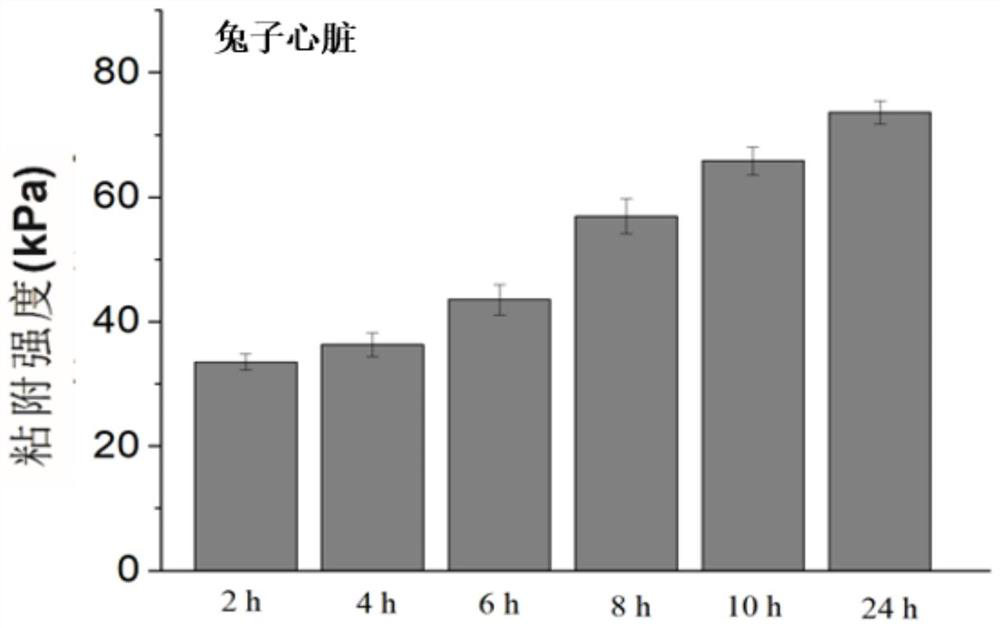

[0077] Use a double-barrel syringe to extrude solution I and genipin solution (volume ratio of 1.5:1) to the surface of pigskin, rabbit heart, aminated glass, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com