Application of new nitrided steel in manufacturing of diesel engine plunger and barrel assembly

A technology of plunger coupler and nitriding steel, applied in the direction of manufacturing tools, engine components, pistons, etc., can solve problems such as adverse effects on performance, poor pulse-shaped nitrides, and low resistance to high-frequency impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

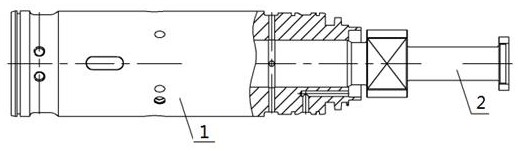

Image

Examples

Embodiment Construction

[0018] The application of a kind of new nitrided steel of the present invention in the manufacture of diesel engine plunger coupler is characterized in that the chemical composition of the new nitrided steel selected to manufacture diesel engine plunger coupler is: carbon, 0.33wt%; silicon , 0.63wt%; Manganese, 0.73wt%; Chromium, 3.35wt%; Molybdenum, 0.59wt%; Vanadium, 0.28wt%; impurity, which is an aluminum-free nitrided steel; comprising the following steps:

[0019] The first step is pretreatment before nitriding; the round steel of φ85×305mm is roughly machined to form the blank of the plunger pair, that is, the workpiece, and the workpiece is quenched and tempered to ensure that the core of the workpiece has a better comprehensive mechanical properties;

[0020] Quenching and tempering treatment procedure: first put the workpiece into the air heating furnace, and the interval between the workpieces in the furnace is ≥20mm; then heat up to raise the furnace temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com