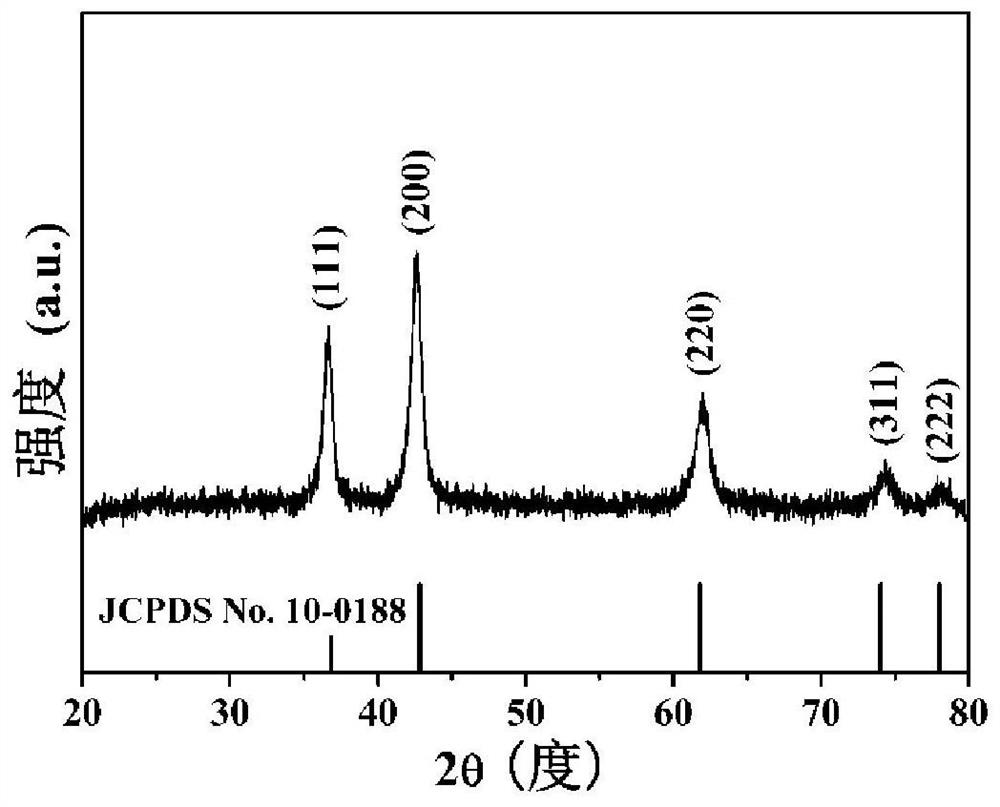

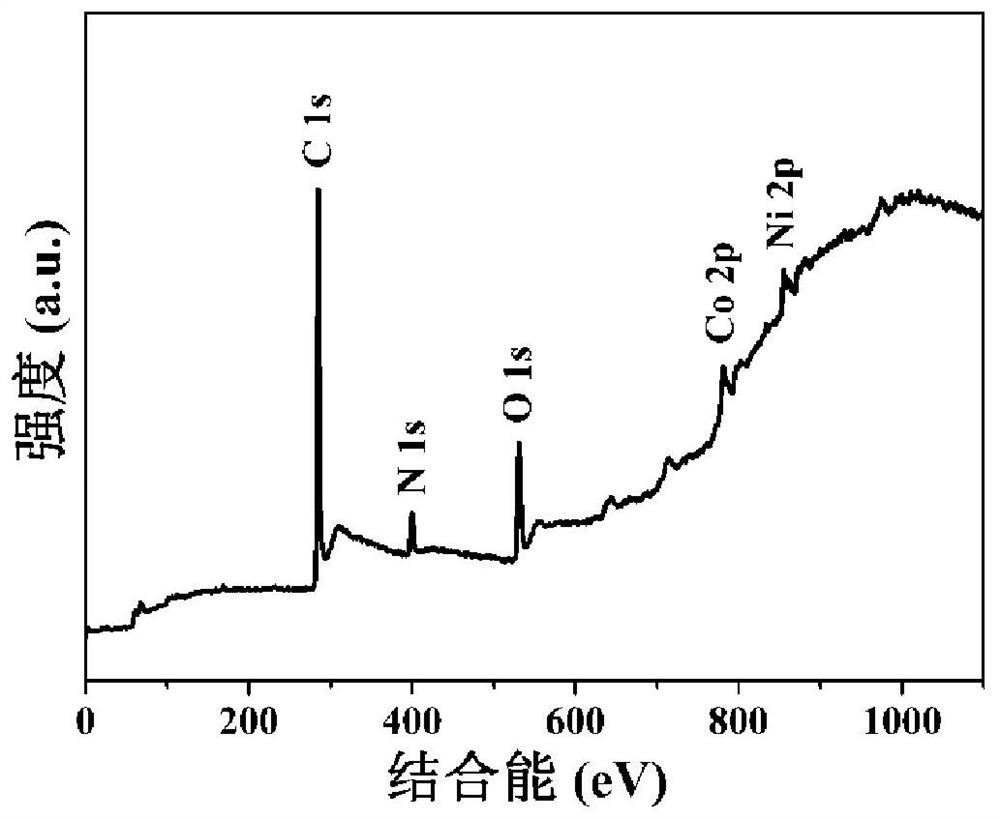

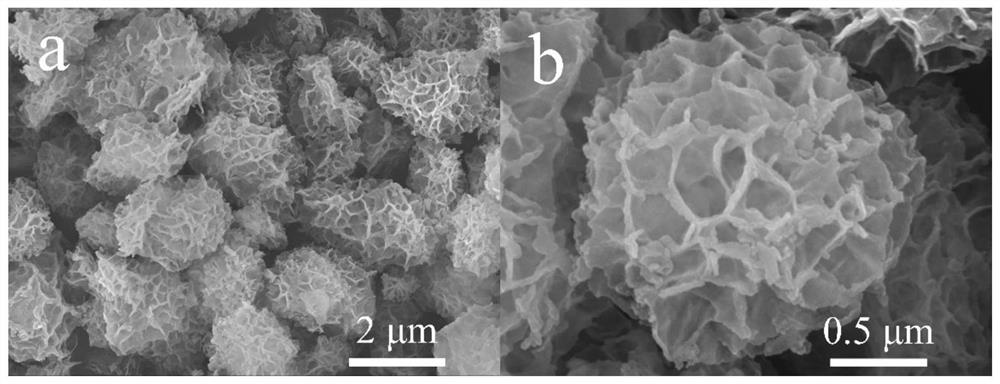

A carbon-coated nickel cobalt oxide multi-dimensional assembled microsphere negative electrode material and preparation method

A technology of carbon-coated cobalt acid and negative electrode materials, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve problems such as poor conductivity and unstable structure, and achieve excellent structural stability The effect of high stability, simple and mild preparation method, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 0.22g nickel nitrate hexahydrate and 0.22g cobalt nitrate hexahydrate were stirred and dissolved in a mixed solvent of 45mL isopropanol, 30mL ethylene glycol and 1.5mL deionized water, placed in an oven for 180 °C solvothera reaction for 12h, after cooling, the precipitation was centrifuged and washed, and dried in a blast drying box to obtain a multidimensional flower-like microsphere precursor;

[0043] (2) The resulting 100mg multidimensional flower-like precursor microspheres were dispersed in 50mL, 10mM and pH =8.5 trimethylolamine aminomethane buffer solution, 50mg of dopamine hydrochloride was added and stirred for surface polymerization, and polydopamine-coated multidimensional flower-like microsphere intermediates were obtained after 12h;

[0044] (3) The polydopamine-coated multidimensional flower-like microsphere intermediates are placed in a protective atmosphere of tubular furnace calcination at 450 °C for 3h, and the heating and cooling rate is 3 °C min -1 A...

Embodiment 2

[0046] (1) 0.093g nickel sulfate hexahydrate and 0.062g cobalt sulfate heptahydrate stirred and dissolved in a mixed solvent of 25mL propanol, 30mL ethylene glycol and 1.4mL deionized water, placed in an oven for 200 °C solvothermal reaction for 6h, after cooling, the precipitation was centrifuged and washed, and dried in a blast drying box to obtain a multidimensional flower-like microsphere precursor;

[0047] (2) The resulting 100mg multidimensional flower precursor microspheres were dispersed in 100mL, 5mM and pH = 7.5 trimethylolamine methane buffer solution, 100mg of dopamine hydrochloride was added and stirred for surface polymerization, and polydopamine-coated multidimensional flower-like bead intermediates were obtained after 6h;

[0048] (3) The polydopamine-coated multidimensional flower-like microsphere intermediates are placed in a tube furnace with a protective atmosphere and calcined at a high temperature of 350 °C for 6 h, and the heating and cooling rate is 0.5 °C...

Embodiment 3

[0050] (1) 0.26g nickel chloride hexahydrate and 0.38g cobalt chloride hexahydrate stirred and dissolved in a mixed solvent of 45mL isopropanol, 30mL propanol and 1.9mL deionized water, placed in an oven for 120 °C solvent thermal reaction for 24h, after cooling, the precipitate was centrifuged and washed, and dried in a blast drying box to obtain a multidimensional flower-like microsphere precursor;

[0051] (2) The resulting 100mg multidimensional flower precursor microspheres were dispersed in 25mL, 15mM and pH = 9.5 trimethylaminomethane buffer solution, 25mg of dopamine hydrochloride was added and stirred for surface polymerization, and polydopamine-coated multidimensional flower-like microsphere intermediates were obtained after 24h;

[0052] (3) The polydopamine-coated multidimensional flower-like microsphere intermediates are calcined at a high temperature of 550 °C in a protective atmosphere tube furnace for 1 h, and the heating and cooling rate is 0.5 °C min -1 After coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com