Hyperelastic silk fibroin micro-nano hybrid fiber aerogel as well as preparation method and application thereof

A silk fibroin and hybrid fiber technology, applied in aerogel preparation, chemical instruments and methods, separation methods, etc., can solve the problems of chemical reagent toxicity, complex process, high cost, and achieve excellent mechanical elasticity and excellent structural properties. , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation method of superelastic silk fibroin micro-nano hybrid fiber aerogel, comprising the following steps:

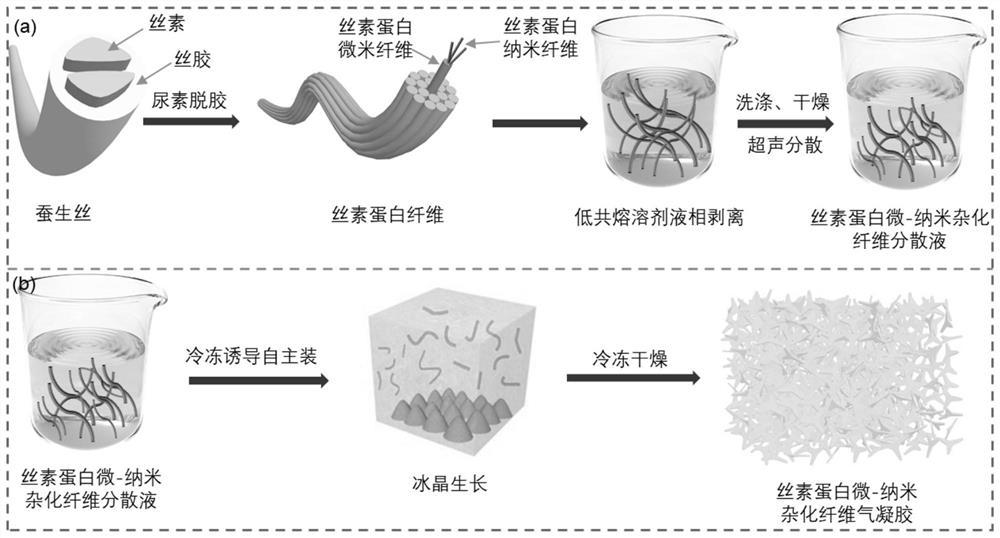

[0054] 1) Silkworm raw silk degumming: In order to avoid the damage to silk fibroin fibers caused by the alkali degumming process, the silkworm raw silk is treated by a non-alkali urea degumming process ( figure 1 shown in a), the specific operation is as follows: put 20 g of silkworm raw silk into an aqueous urea solution with a substance concentration of 8 mol / L at room temperature, then slowly heat it to 90 ° C, and degumming it at 90 ° C for 3h, silkworm The ratio of the mass of raw silk to the volume of the urea solution is 1:30g / ml; after the degumming is completed, the degummed silk is fully washed with deionized water until there is no greasy feeling, and then dried in a 40°C oven to constant weight. Degummed silk, called silk fibroin fibers, is obtained and stored in the dark.

[0055] 2) Extraction of silk fibroin micro-nano hybrid fibers: Mix ...

Embodiment 2

[0063] A preparation method of superelastic silk fibroin micro-nano hybrid fiber aerogel, comprising the following steps:

[0064] 1) silkworm raw silk degumming: with step 1 in Example 1);

[0065] 2) Extraction of silk fibroin micro-nano hybrid fibers: Mix 139.63 g of choline chloride and 90.08 g of DL-lactic acid, and heat at 100°C to form a clear and transparent liquid, namely choline chloride / Lactic acid deep eutectic solvent, wherein the ratio of the amount of choline chloride and lactic acid is 1:1; Weigh 1 g of the silk fibroin fibers obtained in Example 1, cut into pieces, and mix with 100 g of choline chloride prepared above Alkali / lactic acid deep eutectic solvent was mixed, peeled at 100 °C for 48 hours to obtain a paste-like mixture, in which the mass ratio of silk fibroin fibers and deep eutectic solvent was 1:100; deionized water was added to the paste-like mixture , the mass ratio of the two is 1:10, after mixing evenly, carry out suction filtration and washi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com