Crack plugging and tracing system, and preparation method and application of microcapsule

A microcapsule and tracer technology, applied in the field of crack repair, can solve problems such as carbonization, affecting the durability and safety of concrete materials, and defects in auxiliary materials, and achieve the effect of prolonging the degradation time and avoiding premature cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

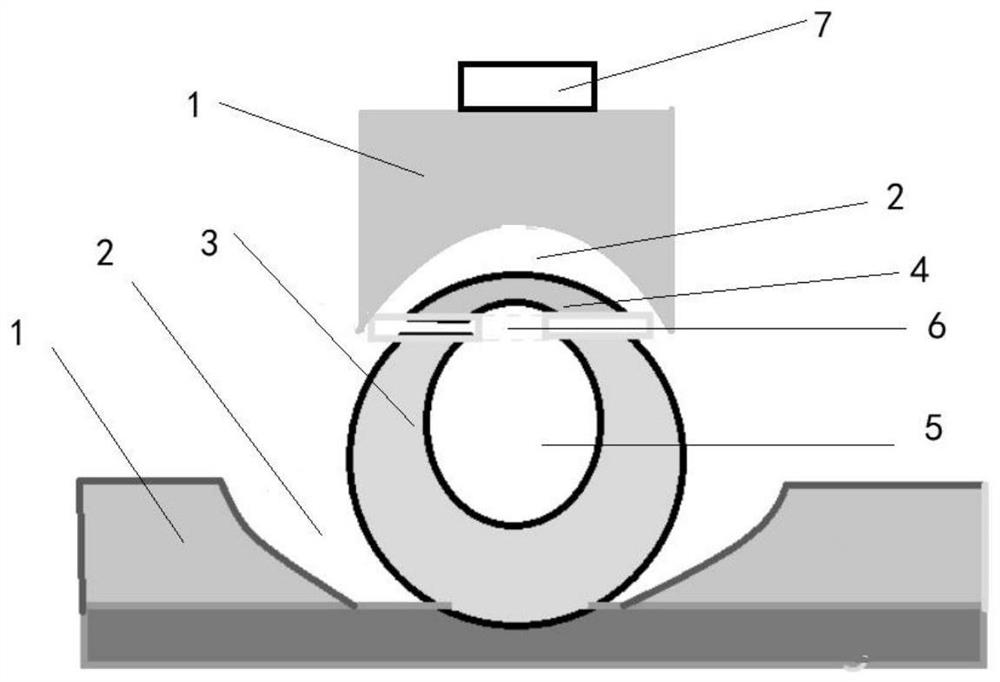

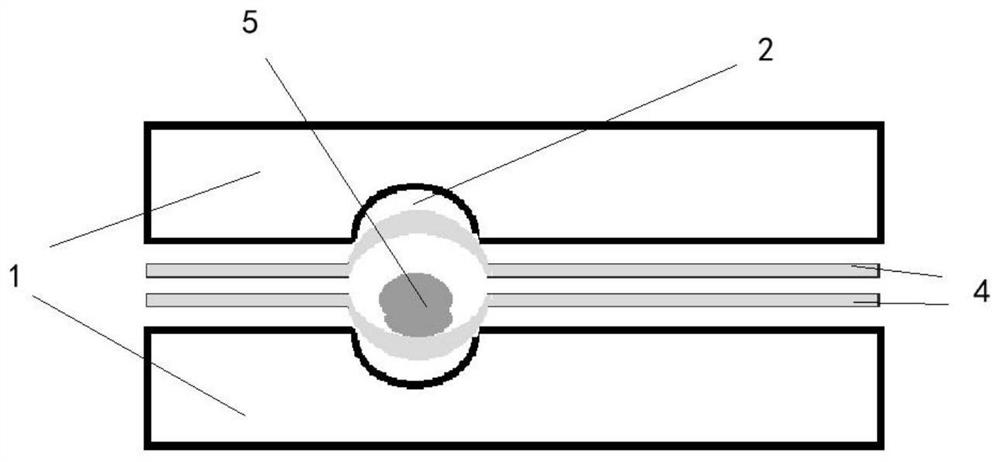

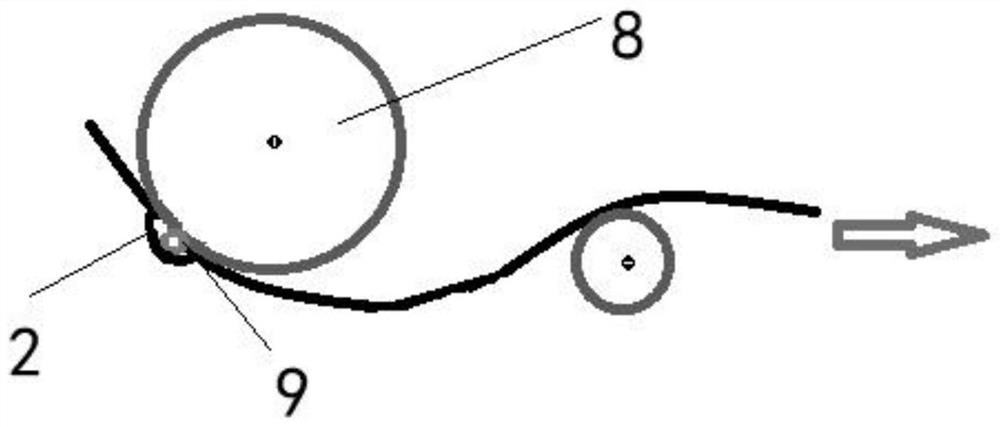

Method used

Image

Examples

Embodiment 1

[0057] (1) The raw material composition of microcapsule:

[0058] The core material of the first reaction microcapsule is epoxy resin with an epoxy value of 0.45, and the wall material is polyethylene.

[0059] The core material of the second reaction microcapsule is 1,2-propylenediamine, sodium silicate, DMP-30 and nonylphenol, and the wall material is polyethylene. Among them, the mass ratio of 1,2-propylenediamine and sodium silicate amine is 5:1, and the mass ratio of DMP-30 and nonylphenol is 2:1.

[0060] The core material of the tracer microcapsule is cyclohexanedicarboxylic acid, sodium α-alkenyl sulfonate, crotonic acid, ethanol solution and azobisisobutyronitrile, and the wall material is polyethylene. The preparation method of the core material of tracer microcapsule is as follows:

[0061] Add cyclohexanedicarboxylic acid, sodium α-alkenyl sulfonate, crotonic acid, ethanol solution and azobisisobutyronitrile in a mass ratio of 0.4:10:13:20:0.002 into a high-press...

Embodiment 2

[0078] Taking the first reaction microcapsules as an example, under the premise that other conditions are the same, only the dry hot air blowing condition of step (2) in embodiment 1 is changed, and 9 groups of experiments are designed to observe the effect of the dry hot air blowing condition on the formation of microcapsules. Impact. The conditions of the test and the molding conditions of the microcapsules are shown in Table 2 below. According to the data analysis, under the condition that the temperature of the lower mold is 15°C, the temperature of the hot air is 80°C, and the blowing time is 1s, the molding condition of the microcapsules is the best.

[0079] Table 2

[0080]

Embodiment 3

[0082] The first reaction microcapsules, the second reaction microcapsules and the tracer microcapsules prepared in Example 1 are poured into the tower foundation concrete that has been stirred evenly and not solidified with a pouring device in a ratio of 1:1:1 by weight. Material, and then clad on the main material of tower base tower foot. Make sure that the three kinds of microcapsules are mixed into the concrete material of the base tower foot, and the distribution area of the three kinds of microcapsules in the concrete material is within 5mm-10mm from the main material of the tower foot, and more than 15mm away from the outer surface of the concrete material. Use vibrating equipment to vibrate the concrete pool at the base of the tower. After the concrete material is solidified, use a black light (320-420nm) and a defect photographing device (including a photographing device with an ultraviolet sensitive screen) to trace and detect the coating position of the tower foo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com