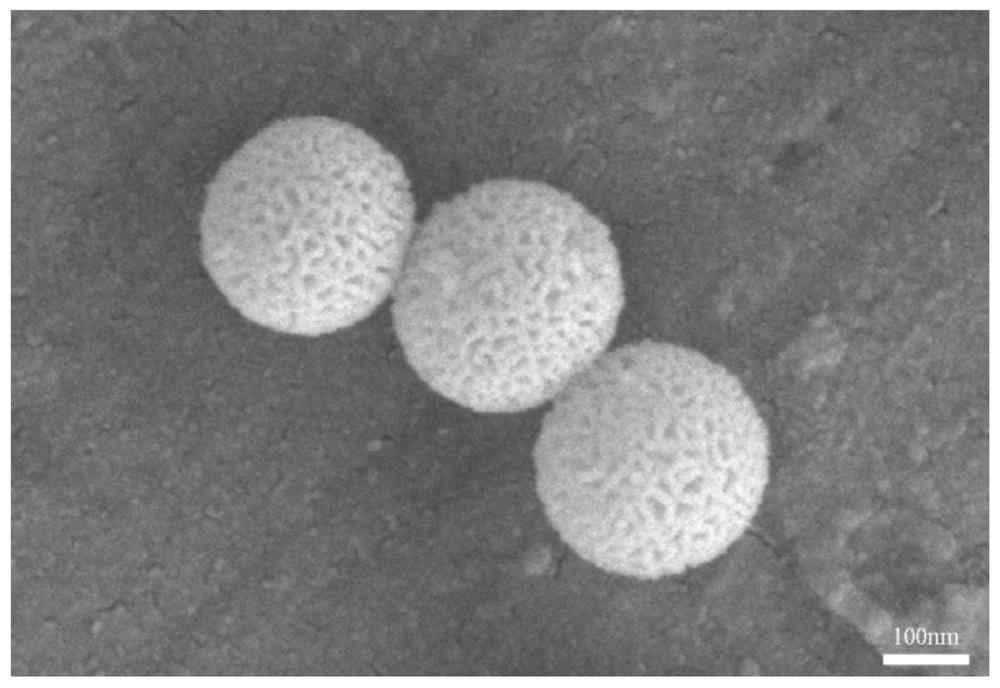

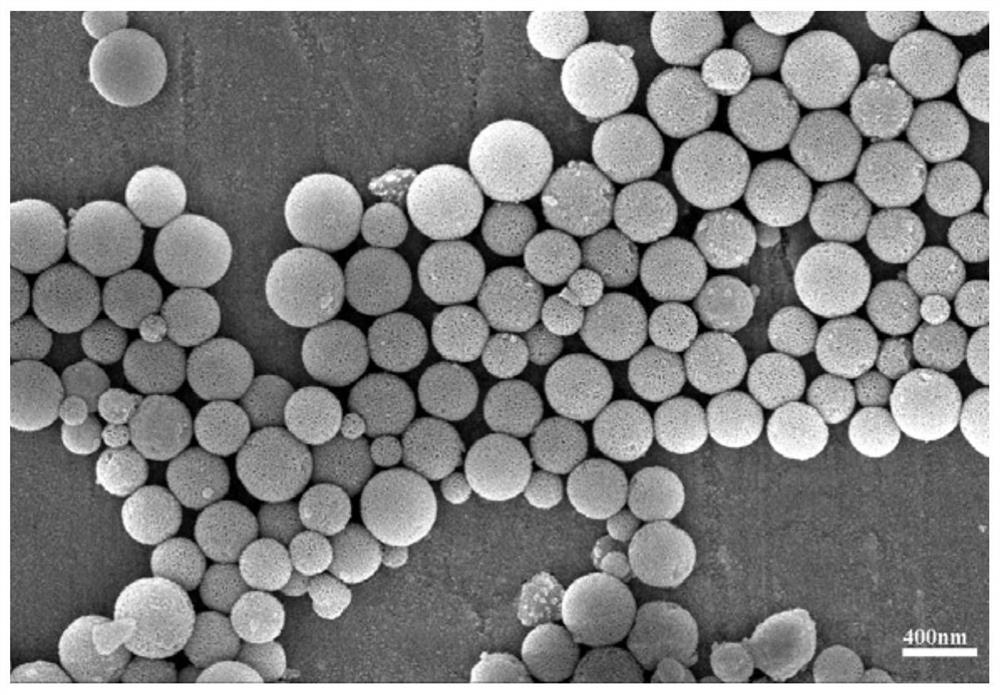

Mesoporous bioactive glass/chitosan composite hemostatic sponge and preparation method thereof

A technology of bioactive glass and hemostatic sponge, which is applied in the field of medical devices, achieves the effect of simple method, broad application prospect and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A mesoporous bioactive glass / chitosan composite hemostatic sponge and a preparation method thereof, the preparation method of which is as follows:

[0047] (1) Preparation steps of mesoporous bioactive glass powder:

[0048] 1) Dissolve 0.6g of urea and 2g of cetylpyridinium bromide (CPB) in 150ml of deionized water, and stir evenly;

[0049] 2) After adding 42ml of cyclohexane, add 0.84g of isopropanol as a surfactant, and stir vigorously to form a uniform emulsion;

[0050] 3) Use a syringe pump to add 4.8g tetraethyl orthosilicate (TEOS) dropwise at a rate of 2ml / min. After reacting at room temperature for 30 minutes, add 0.6g triethyl phosphate (TEP) dropwise, and react for 30 minutes and then heat up to Continue to react for 12 hours at 70°C under the conditions of oil bath and condensing reflux, then add 3.112g of calcium nitrate tetrahydrate (CN), continue to react for 4 hours, cool to room temperature, and age for 18 hours;

[0051] 4) Centrifuge at 10,000r / mi...

Embodiment 2

[0058] A mesoporous bioactive glass / chitosan composite hemostatic sponge and a preparation method thereof, the preparation method of which is as follows:

[0059] (1) Preparation steps of mesoporous bioactive glass powder:

[0060] 1) Dissolve 1.6g of urea and 8g of cetylpyridinium bromide (CPB) in 192ml of deionized water, and stir well;

[0061] 2) After adding 128ml of cyclohexane, add 2g of isopropanol as a surfactant, and stir vigorously to form a uniform emulsion;

[0062] 3) Use a syringe pump to add 14.5g tetraethyl orthosilicate (TEOS) dropwise at a speed of 2ml / min. After reacting at room temperature for 30 minutes, add 0.483g triethyl phosphate (TEP) dropwise, and heat up to Continue to react for 12 hours at 70°C under the conditions of oil bath and condensing reflux, then add 2.507g of calcium nitrate tetrahydrate (CN), continue to react for 4 hours, cool to room temperature, and age for 24 hours;

[0063] 4) Centrifuge at 10,000r / min for 20min, wash with acetone...

Embodiment 3

[0070] A mesoporous bioactive glass / chitosan composite hemostatic sponge and a preparation method thereof, the preparation method of which is as follows:

[0071] (1) Preparation steps of mesoporous bioactive glass powder:

[0072] 1) Dissolve 1.333g of urea and 8g of cetylpyridinium bromide (CPB) in 200ml of deionized water, and stir evenly;

[0073] 2) After adding 120ml of cyclohexane, add 1.5g of isopropanol as a surfactant, and stir vigorously to form a uniform emulsion;

[0074] 3) Use a syringe pump to add 13.33g tetraethyl orthosilicate (TEOS) dropwise at a rate of 2ml / min. After reacting at room temperature for 30 minutes, add 0.256g triethyl phosphate (TEP) dropwise, and react for 60 minutes and then heat up to Continue to react for 12 hours at 75°C under the conditions of oil bath and condensing reflux, then add 1.329g of calcium nitrate tetrahydrate (CN), continue to react for 5 hours, cool to room temperature, and age for 24 hours;

[0075] 4) Centrifuge at 10,0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com