Method and device for firing lime and producing CO2 as byproduct by using totally-enclosed multiple kilns in series with oxygen

A fully enclosed CO2 technology, applied in chemical instruments and methods, inorganic chemistry, energy input, etc., can solve the problems of lack of effective methods for recycling, difficulty in separating and purifying carbon dioxide, and high production cost of carbon dioxide, so as to achieve easy purification and recycling, Elimination of diffusion resistance and reduction of purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

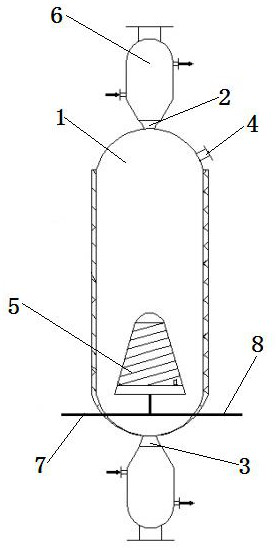

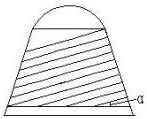

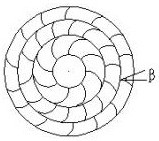

[0041] Such as Figure 1~3 As shown, the fully enclosed multi-kilns are connected in series to burn lime with oxygen and by-produce CO 2 The device comprises two lime kilns 1, flue gas waste heat boiler 11, negative pressure air extractor 12, first flue gas pipeline 9, second flue gas pipeline 10, auxiliary gas pipeline 7, fuel gas pipeline 8; each Lime kiln 1 is provided with a tangential spiral gas distribution cap 5, the tangential spiral gas distribution cap 5 is a tower type tangential spiral gas distribution cap, which is divided into 3 layers, each layer has a vertical angle α of 2° and a horizontal angle of β is 5°; the top of the lime kiln 1 is provided with a material inlet 2 and a flue gas outlet 4 respectively, and the bottom of the lime kiln 1 is provided with a material outlet 3; one end of the first flue gas pipe 9 is connected to the flue gas The hot phase inlet of the gas waste heat boiler 11 is connected; the hot phase outlet of the flue gas waste heat boile...

Embodiment 2

[0046] Fully enclosed multi-kiln connected in series to burn lime with oxygen and produce CO by-product 2 device, which includes three lime kilns 1, flue gas waste heat boiler 11, negative pressure air extractor 12, first flue gas pipeline 9, second flue gas pipeline 10, auxiliary gas pipeline 7, fuel gas pipeline 8; each Lime kiln 1 is provided with a tangential spiral gas distribution hood 5, the tangential spiral gas distribution hood 5 is a tower type tangential spiral gas distribution hood, which is divided into 5 layers, the vertical angle α of each layer is 30°, and the horizontal angle β is 45°; the top of the lime kiln 1 is provided with a material inlet 2 and a flue gas outlet 4 respectively, and the bottom of the lime kiln 1 is provided with a material outlet 3; one end of the first flue gas pipe 9 is connected to the flue gas The hot phase inlet of the gas waste heat boiler 11 is connected; the hot phase outlet of the flue gas waste heat boiler 11 is connected with...

Embodiment 3

[0051] Fully enclosed multi-kiln connected in series to burn lime with oxygen and produce CO by-product 2 The device is different from the device described in Embodiment 2 in that: the tangent spiral gas distribution cap 5 is a tower-type tangent spiral gas distribution cap, which is divided into 4 layers, and the vertical angle α of each layer is 4°, and the lateral angle β is 8°; the lime kiln 1 is a rotary kiln; the material inlet 2 and the material outlet 3 of the lime kiln 1 are connected with a gas replacement device 6; the flue gas waste heat boiler 11 is a tubular heat exchanger; The negative pressure air extractor 12 is a negative pressure twin-screw type air extraction compressor.

[0052] Fully enclosed multi-kiln connected in series to burn lime with oxygen and produce CO by-product 2 method, using the fully enclosed multi-kiln series oxygen burning lime described in this example and by-product CO 2 device, specifically as Image 6 As shown, three lime kilns 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com