Low-dielectric polyimide film and preparation method thereof

A polyimide film and polyimide technology, applied in the field of microelectronics, can solve the problems of unsatisfactory and high dielectric constant, and achieve lower dielectric constant, good heat resistance, good thermal stability and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the embodiment of the present invention, the preparation method of the low dielectric polyimide film comprises the following steps,

[0032] (1) Add tris(4-aminophenyl)amine to the polyamic acid solution with a mass concentration of 10-20%, stir to obtain a polyamic acid solution containing a cross-linked structure, and cast the polyamic acid solution evenly onto a glass plate placed in a vacuum oven to remove air bubbles and dry. In the present invention, the polyamic acid solution is polymerized in situ in a polar solvent by biphenyltetracarboxylic dianhydride (BPDA), 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene (6FAPB) get, the condition is N 2 In the atmosphere, stir at room temperature for 3 to 8 hours; the selected polar solvent of the present invention is N, N-dimethylformamide (DMF), N, N-dimethylacetamide (DMAC), N-methylpyrrolidone (NMP); in the present invention, the selected time for removing air bubbles is 3 to 10 minutes.

[0033] (2) Place the d...

Embodiment 1

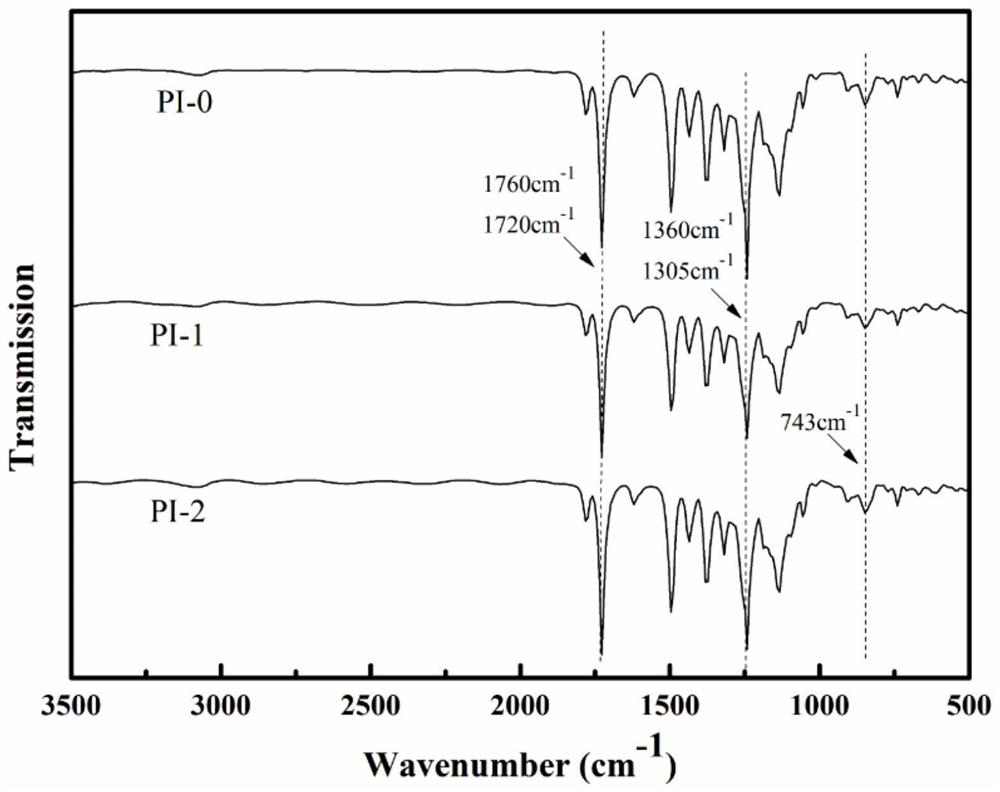

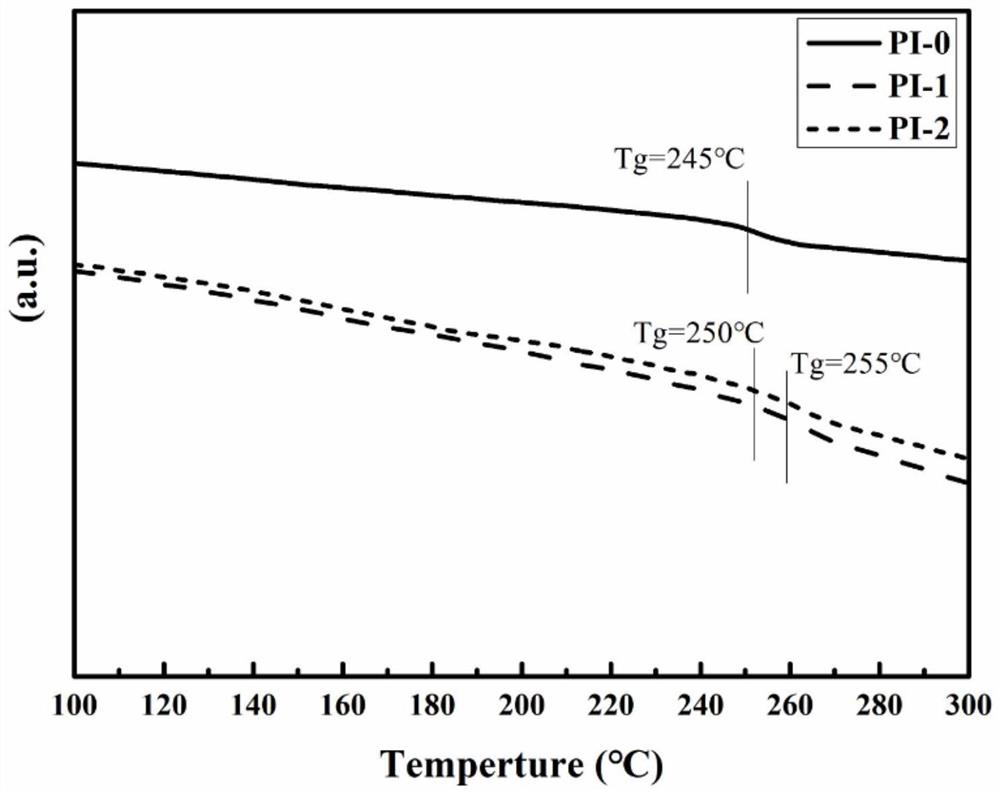

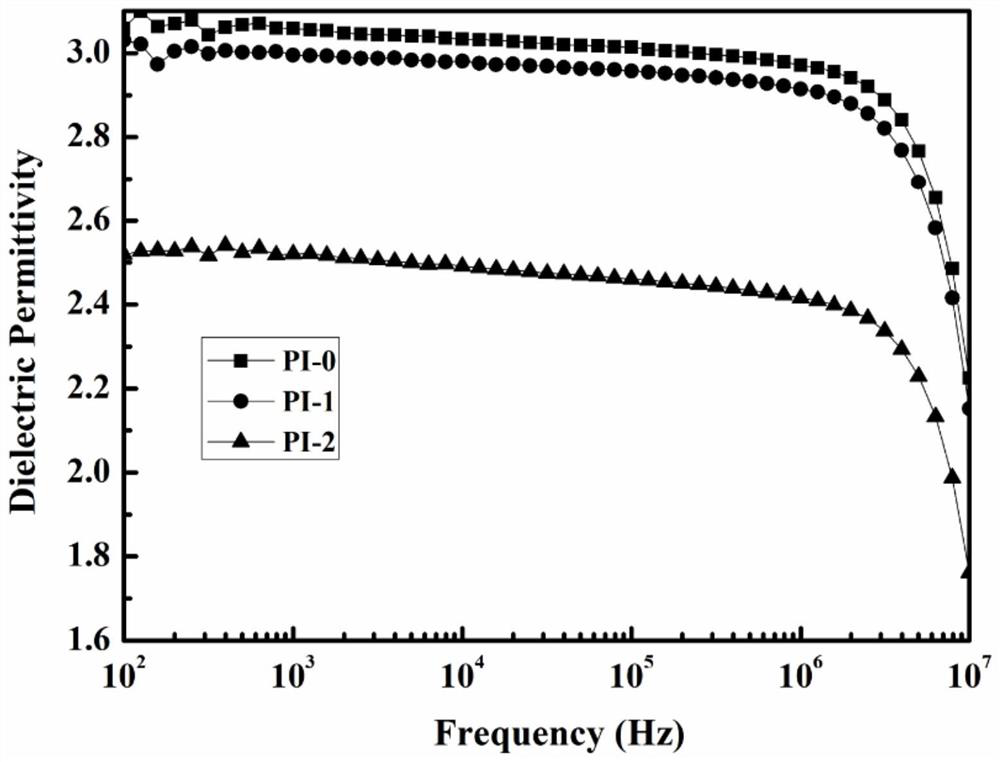

[0038] Dissolve 0.5090g 6FAPB in 3.927ml DMAC, stir until completely dissolved; then add 0.3530g BPDA in three batches, and 2 Stir at room temperature for 5 h in an atmosphere to obtain a homogeneous viscous solution with a mass concentration of 18%. Then add 0.0023g of TPA, stir in an ice-water bath for 5 minutes, and after it is completely dissolved, place the above mixed system in a vacuum oven at 60°C for 3 minutes to remove air bubbles. Finally, cast it on a dry glass plate by casting method, place it in a blast drying oven, and carry out thermal amidation in a temperature gradient of 80-300°C (80°C, 100°C, 200°C, 300°C for 1h each) , the heating rate is 6°C / min), the cross-linked polyimide film PI-1 can be obtained, and its dielectric constant is 2.15 (f=10 7 Hz).

Embodiment 2

[0040] Dissolve 0.5040g 6FAPB in 3.927ml DMAC, stir until completely dissolved; then add 0.3530g BPDA in batches, and 2 Stir at room temperature for 5 h in an atmosphere to obtain a homogeneous viscous solution with a mass concentration of 18%. Then add 0.0050g TPA, stir in an ice-water bath for 5 minutes, and after it is completely dissolved, put the above mixed system in a vacuum drying oven to remove air bubbles for 3 minutes. Finally, cast it on a dry glass plate by casting method, place it in a blast drying oven, and carry out thermal amidation in a temperature gradient of 80-300°C (80°C, 100°C, 200°C, 300°C for 1h each) , the heating rate is 6°C / min), the cross-linked polyimide film PI-2 can be obtained, and its dielectric constant is 1.76 (f=10 7 Hz).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com