Waste oil curing agent, preparation method and application

A curing agent and monohydric technology, applied in chemical modification of fatty acids, fatty acid production, etc., can solve the problems of secondary pollution, leakage, etc., achieve good solidification state, good dispersion, and solve the collection and transshipment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The raw materials of a new type of waste oil curing agent are composed according to the following weight percentages: 89% by mass of 12-hydroxystearic acid, 2% by mass of magnesium silicate monohydrate, 3% by mass of starch, and 3% by mass of ethanol. 6%.

[0037] After mixing the above substances in proportion, stir the mixture evenly with a glass rod, put the mixture into an MMCS-900 ultrasonic cleaner, and vibrate for 5 minutes at a selected frequency of 2.8MHz under normal pressure. Take out the uniformly mixed product, put it into a DZF-6030 desktop vacuum drying oven to dry, set the temperature at 20°C, and the drying time is 2.5h. After the drying is completed, grind it to 20 mesh to obtain the curing agent 12- HSA.

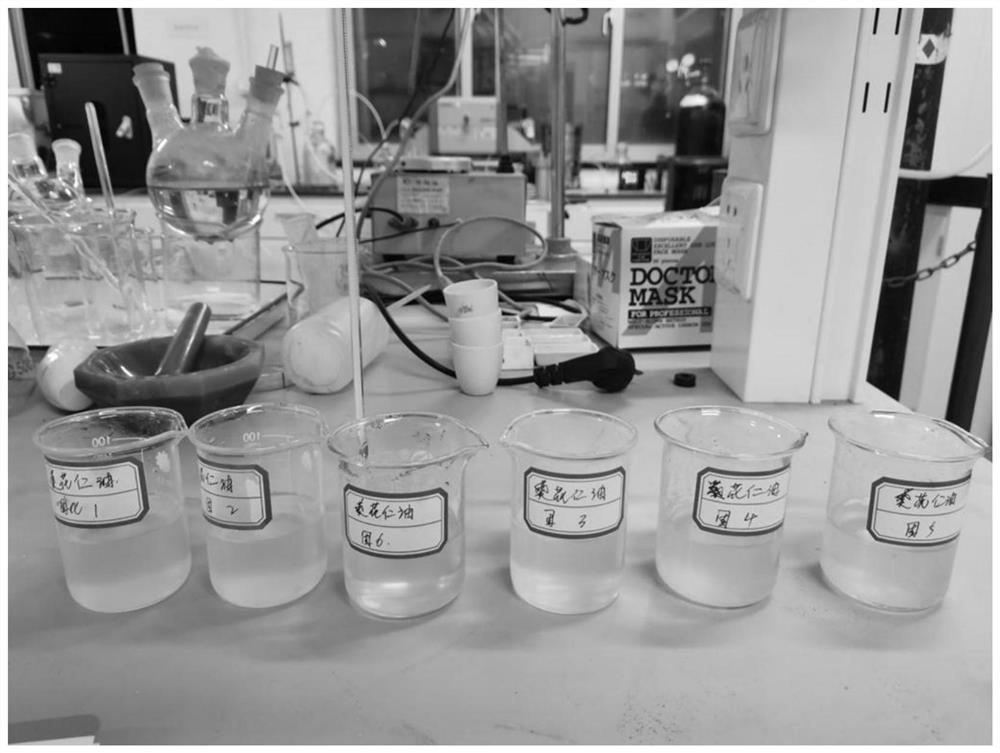

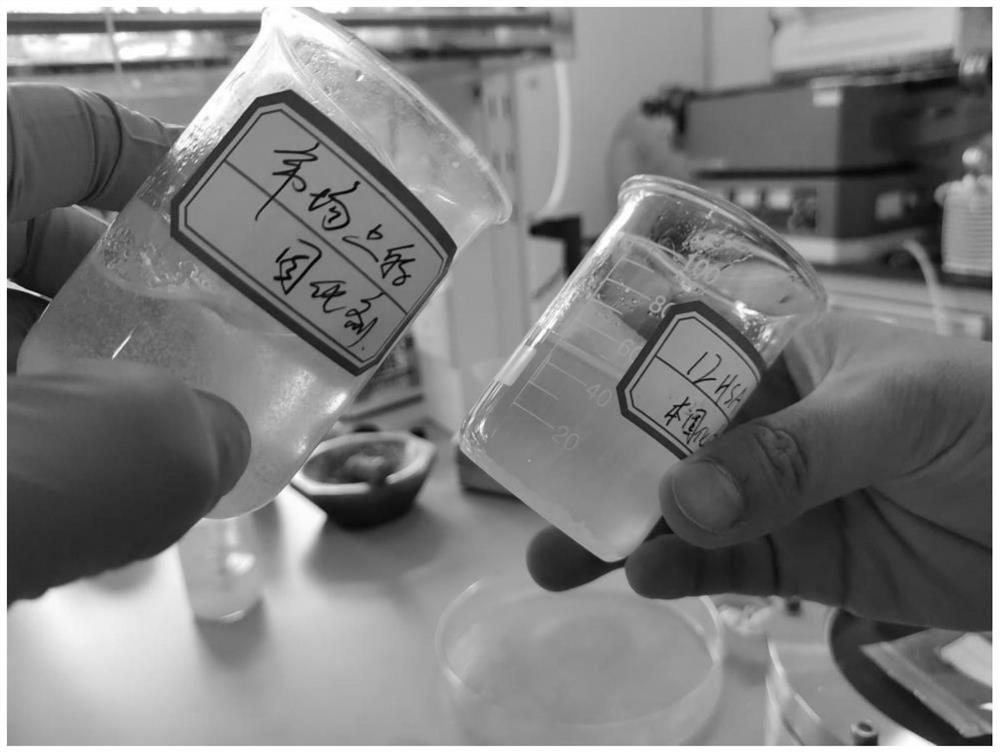

[0038] Take 90ml of sunflower kernel oil, respectively numbered "12-HSA" and "curing agent on the market", heat the oil to 100 ° C, slowly cool to 80 ° C, and the curing agent 12-HSA prepared in this example Take 2.5g and 2.5g of the commercially ...

Embodiment 2

[0042] The raw materials of a new type of waste oil curing agent are composed according to the following weight percentages: 12-hydroxystearic acid mass percentage is 92%, magnesium silicate monohydrate is 2% by mass percentage, starch mass percentage is 1%, ethanol mass percentage is 5%.

[0043] After mixing the above substances in proportion, stir the mixture evenly with a glass rod, put the mixture into an MMCS-900 ultrasonic cleaner, and vibrate for 5 minutes at a selected frequency of 2.8MHz under normal pressure. The homogeneously mixed product was taken out and put into a DZF-6030 desktop vacuum drying oven for drying, the temperature was set at 20°C, and the drying time was 2.5 hours. After drying, it is ground to 20 meshes to obtain the curing agent 12-HSA.

[0044] Take 100ml of sunflower kernel oil, respectively numbered "12-HSA" and "curing agent on the market", heat the oil to 100°C, slowly cool to 85°C, and take 2.7g of the curing agent prepared in this example...

Embodiment 3

[0046] The raw materials of a novel waste oil curing agent are composed according to the following weight percentages: 12-hydroxystearic acid mass percentage is 85%, magnesium silicate monohydrate is 6% by mass percentage, starch mass percentage is 5%, ethanol mass percentage is 4%.

[0047] After mixing the above substances in proportion, stir the mixture evenly with a glass rod, put the mixture into an MMCS-900 ultrasonic cleaner, and vibrate for 5 minutes at a selected frequency of 2.8MHz under normal pressure. The homogeneously mixed product was taken out and put into a DZF-6030 desktop vacuum drying oven for drying, the temperature was set at 20°C, and the drying time was 2.5 hours. After drying, grind to 20 meshes to obtain curing agent 12-HSA.

[0048]Take 100ml of sunflower kernel oil respectively, numbered "12-HSA" and "curing agent on the market", heat the oil to 100°C, and slowly cool to 78°C, the curing agent 12-HSA prepared in this example Take 2.7g and 2.2g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com