Method for high-throughput screening of alpha-keto acid high-producing strains

A high-yield, high-throughput technology, applied in the field of bioengineering, can solve the problems that amino acids are insoluble in buffers, impractical, and unable to prepare high-concentration substrate mother solutions, so as to reduce the risk of contamination, improve efficiency, and improve composition. rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

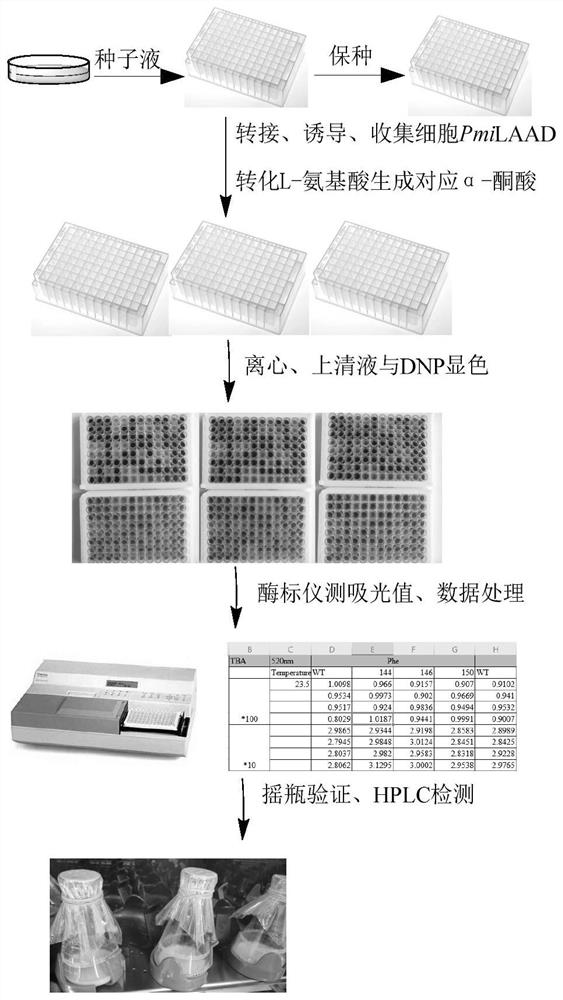

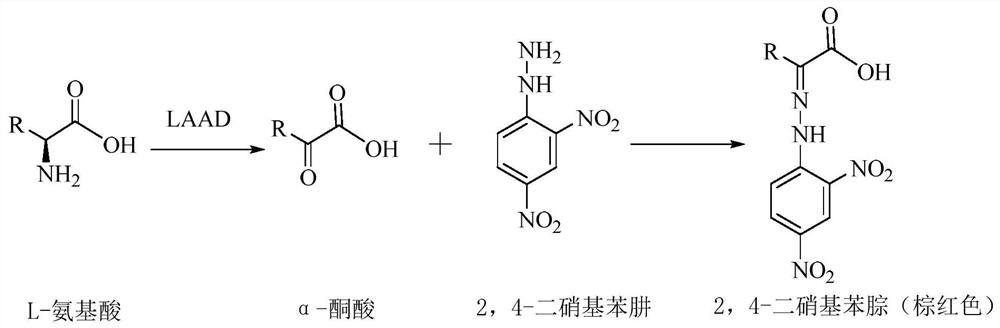

[0059] Embodiment 1 high-throughput screening

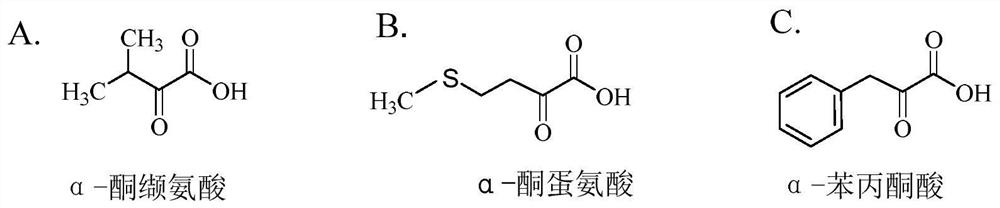

[0060] According to the structural characteristics of the crystallized L-amino acid deaminase, homology modeling was carried out and 5 amino acid sites at the substrate channel were screened for mutation, and then high-throughput screening technology was used to screen out high-yield mutants.

[0061] 1. Construction of a strain expressing L-amino acid deaminase PmiLAAD mutant

[0062] Primer design: the five amino acid sites are D144, K146, K150, H295, and H301 respectively, and saturation mutation primers are designed for these five sites. The nucleic acid sequences of the primers are as shown in SEQ ID NO.3, SEQ ID NO.4, Shown in SEQ ID NO.5, SEQ ID NO.6, SEQ ID NO.7, SEQ ID NO.8, SEQ ID NO.9, SEQ ID NO.10, SEQ ID NO.11 and SEQ ID NO.12 (as shown in the table 3).

[0063] Table 3 High-throughput screening mutation primer sequences

[0064]

[0065]

[0066] Mutants were constructed by whole-plasmid PCR: the KOD system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com