Molecular sieve compound and composite material and preparation methods and application thereof

A composite material and molecular sieve technology, applied in the field of molecular sieve composites and composite materials and their preparation, can solve the problems of difficulty in taking into account the desulfurization rate and the penetrating sulfur capacity, and achieve the effects of good adsorption, good regeneration performance, and promotion of development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

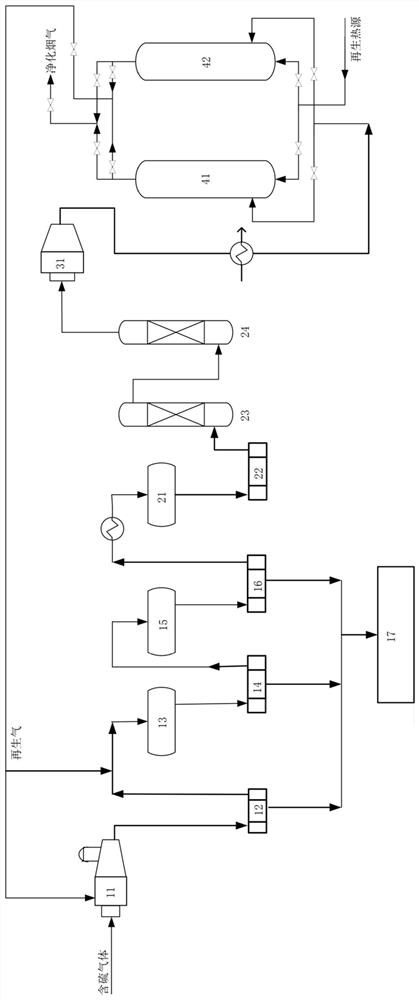

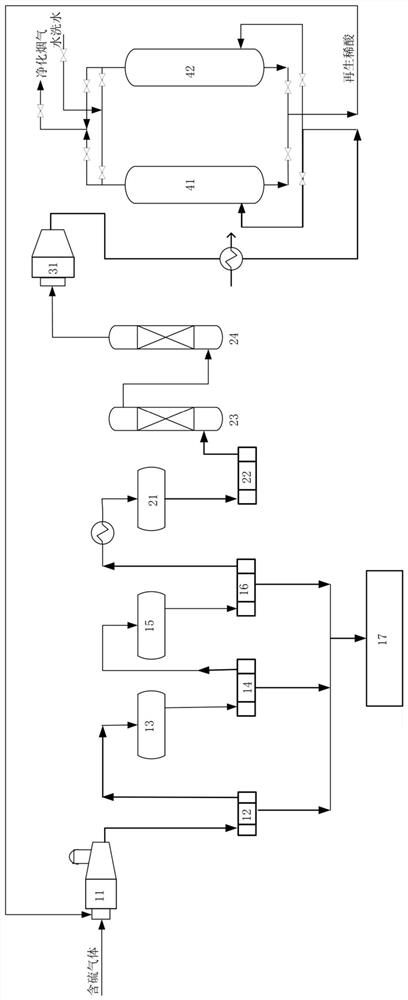

Method used

Image

Examples

preparation example Construction

[0051] According to the method for preparing the molecular sieve composite of the present invention, the amount of the aluminum precursor and the rare earth modified molecular sieve is such that the weight ratio between the aluminum element and the molecular sieve in the obtained molecular sieve composite is preferably (12-28):100.

[0052] According to the method for preparing a molecular sieve composite of the present invention, the amount of the precursor of the alkaline earth metal and the rare earth modified molecular sieve makes the weight ratio between the alkaline earth metal element and the molecular sieve in the obtained molecular sieve composite preferably (0.6-2.1):100 .

[0053] According to the method for preparing the molecular sieve composite of the present invention, the amount of the rare earth element is such that the weight ratio between the rare earth element and the molecular sieve in the obtained molecular sieve composite is preferably (3.7-9.3):100.

[...

Embodiment 1

[0162] Take by weighing 800g of molecular sieve former powder (NaY molecular sieve, silicon-aluminum ratio is 5, specific surface area is 850m 2 / g, the pore volume is 0.32ml / g) is placed in a beaker, and distilled water is added to make the water / molecular sieve weight ratio reach about 8. Weigh 76g cerium chloride (CeCl 3 ·6H 2 O), 30g lanthanum chloride (LaCl 3 ) to make rare earth chloride solution. Add the rare earth chloride solution into the beaker and stir evenly, adjust the pH value to about 4 with hydrochloric acid, place the beaker in a water bath and heat it to about 80°C, exchange for 1 hour while stirring, and the exchange process ends. Cool, filter, wash, dry. In order to increase the exchange depth of the rare earth ions, the molecular sieve after the first exchange was calcined at 550° C. for 4 hours. After roasting, the molecular sieve is exchanged twice according to the above method to obtain a modified molecular sieve.

[0163] Gained modified molecul...

Embodiment 2-7

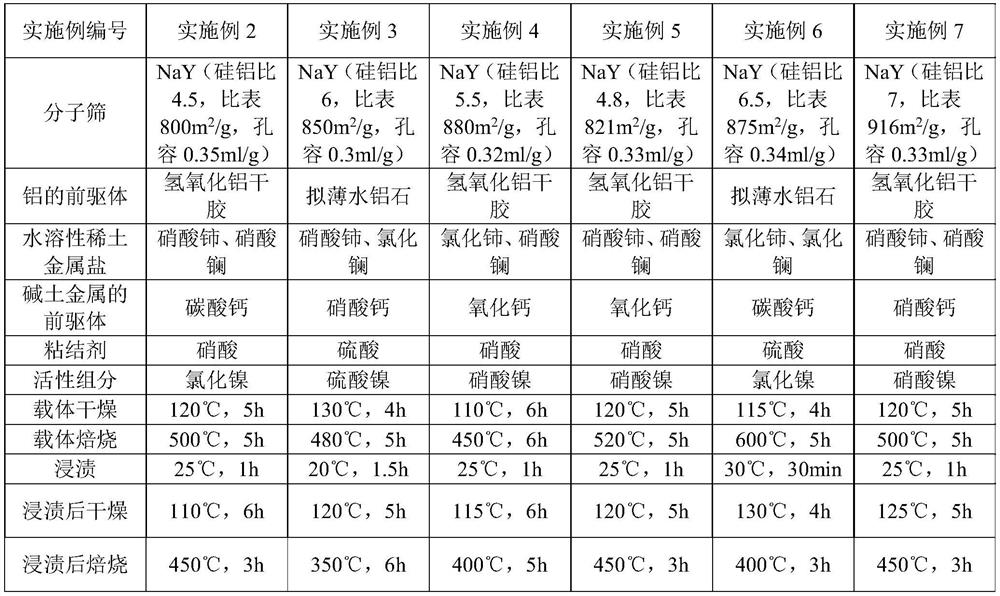

[0166] The adsorbent was prepared according to the various steps and conditions of Example 1, only the composition, preparation conditions or concentration of the impregnation solution were changed. The specific preparation conditions are shown in Table 1. The contents of each metal oxide and molecular sieve in the final adsorbent product are shown in Table 2. As shown, the measurement results of the specific surface area and the like are shown in Table 4.

[0167] Table 1

[0168]

[0169] Table 2

[0170]

[0171]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com