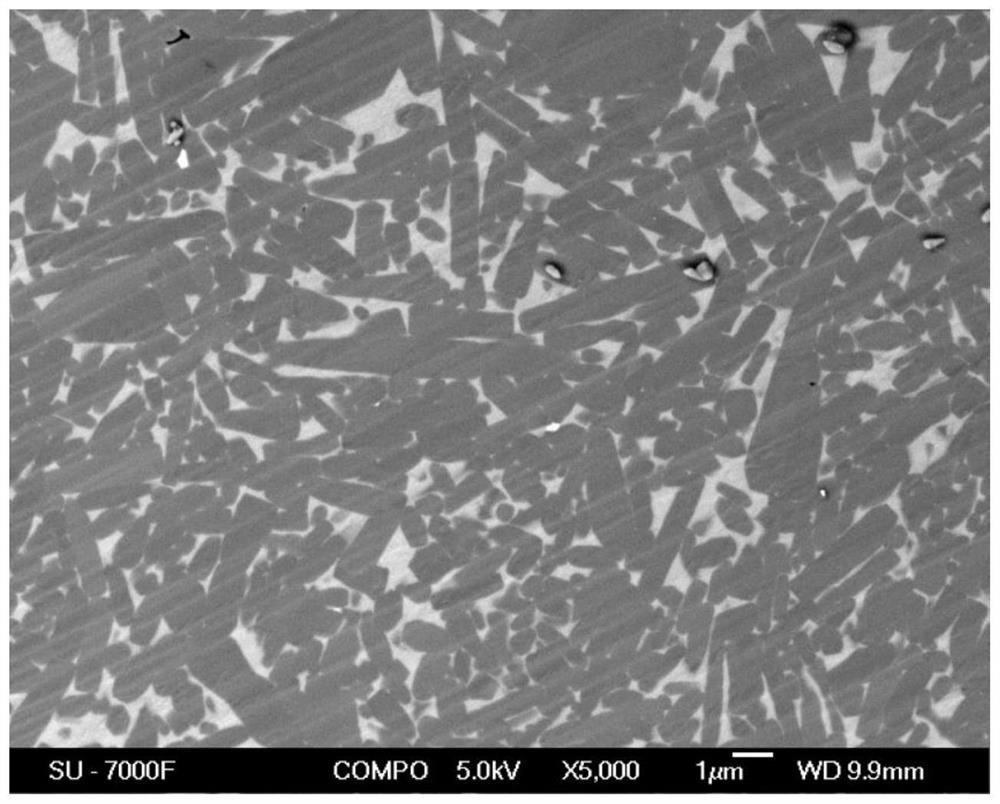

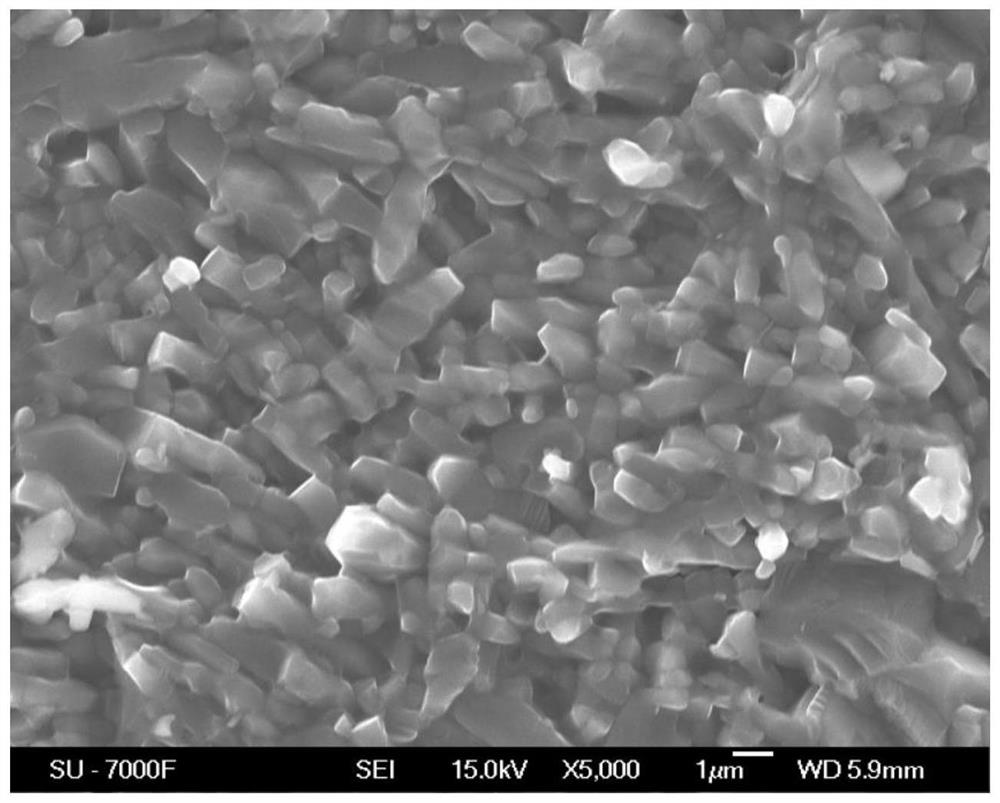

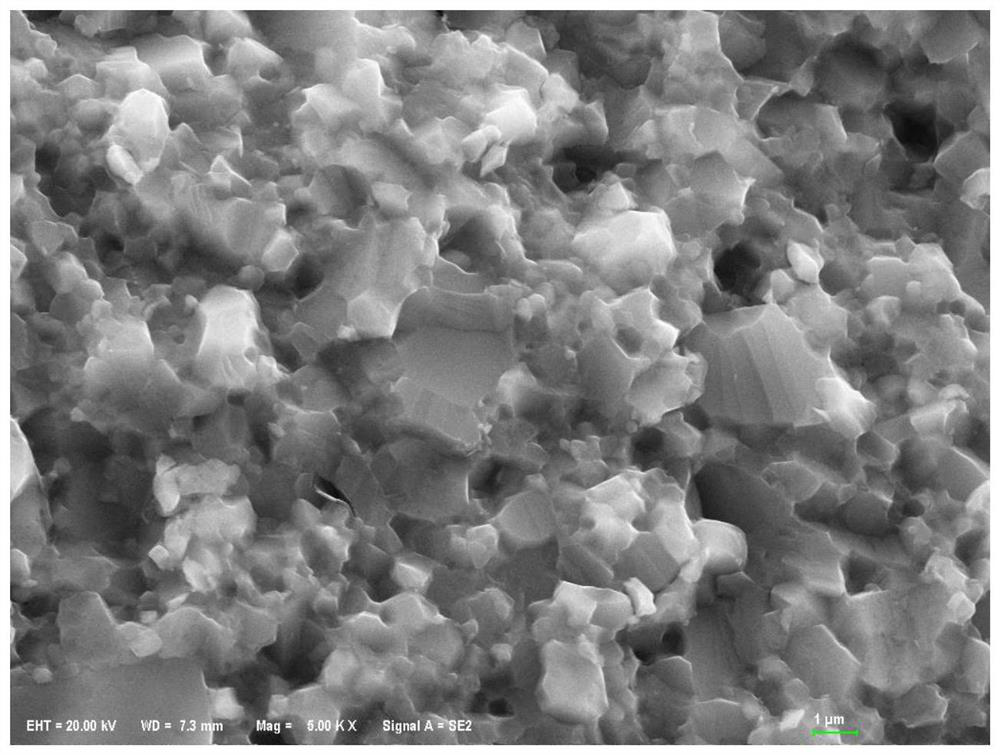

Silicon carbide whisker ceramic with typical long particle morphology and rich in lamination faults and twin crystals and preparation method thereof

A technology of silicon carbide whiskers and ceramics, which is applied in the field of preparation of silicon carbide whiskers ceramics, can solve the problems of limited matrix reinforcement effect, large dispersion of whisker aspect ratio, and failure to retain whisker structure, so as to avoid secondary regeneration Effects of crystallization, high fracture toughness, and rich twin structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 15.39g of yttrium oxide, 12.54g of aluminum oxide, and 22.07g of silicon oxide respectively, add the powder into the ball mill tank for mixing with a planetary ball mill for 6 hours, the mass ratio of material to ball is 1:2, and weigh 50g of absolute ethanol And 100g of silicon nitride balls are used as the ball milling medium, and the ball milling speed is 100r / min. The mixed slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain sintering aid powder. Weigh 10g of pure silicon carbide whiskers and 2g of sintering aid powder, add the two raw materials together into the ball mill tank for mixing for 6 hours, the mass ratio of material to ball is 1:2, weigh 30g of absolute ethanol and 24g of silicon nitride balls As the ball milling medium, the ball milling speed is 100r / min. The mixed ceramic slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain ceramic powder. Select 2g of dried ceramic powder, grind it with ...

Embodiment 2

[0031] Weigh 15.39g of yttrium oxide, 12.54g of aluminum oxide, and 22.07g of silicon oxide respectively, add the powder into the ball mill tank for mixing with a planetary ball mill for 8 hours, the mass ratio of material to ball is 1:2, and weigh 50g of absolute ethanol And 100g of silicon nitride balls are used as the ball milling medium, and the ball milling speed is 100r / min. The mixed slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain sintering aid powder. Weigh 10g of pure silicon carbide whiskers and 2g of sintering aid powder, add the two materials together into a ball mill tank for planetary ball mill mixing for 8 hours, the mass ratio of material to ball is 1:2, weigh 30g of absolute ethanol and 24g of nitrogen Silica balls were used as the ball milling medium, and the ball milling speed was 100r / min. The mixed ceramic slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain ceramic powder. Select 2g of dried c...

Embodiment 3

[0035] Weigh 15.39g of yttrium oxide, 12.54g of aluminum oxide, and 22.07g of silicon oxide respectively, add the powder into the ball mill tank and mix with planetary ball mill for 10 hours, the mass ratio of material to ball is 1:2, and weigh 50g of absolute ethanol And 100g of silicon nitride balls are used as the ball milling medium, and the ball milling speed is 100r / min. The mixed slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain sintering aid powder. Weigh 10g of pure silicon carbide whiskers and 2g of sintering aid powder, add the two raw materials together into a ball mill tank for planetary ball mill mixing for 10h, the mass ratio of material to ball is 1:2, weigh 30g of absolute ethanol and 24g of nitrogen Silica balls were used as the ball milling medium, and the ball milling speed was 100r / min. The mixed ceramic slurry was dried by rotary evaporation at 60°C and vacuum oven at 60°C to obtain ceramic powder. Select 2g of dried ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com