Animal excrement and straw bio-organic fertilizer and preparation method thereof

A technology of straw biomass and animal manure, which is applied in the treatment of biological organic parts, organic fertilizers, microorganisms, etc., can solve the problems of air pollution, pollution, waste of resources and the environment, etc., to promote crop growth, reduce environmental pollution, and increase crop yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

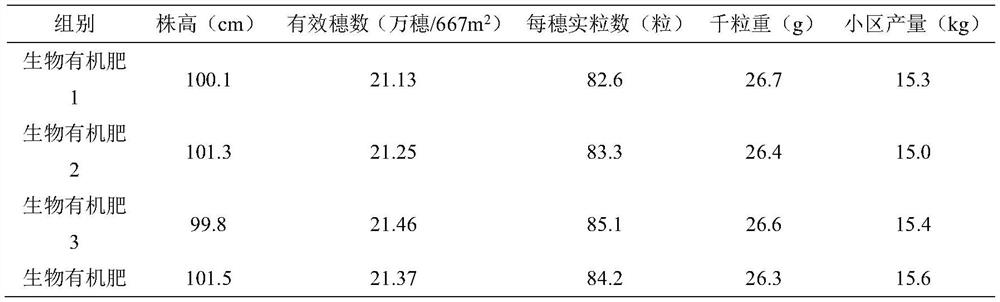

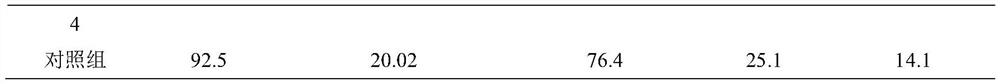

Embodiment 1

[0030] The raw materials of the bio-organic fertilizer in this embodiment include 60 parts by weight of animal manure and urine, 33 parts of straw, 0.23 part of straw decomposing agent and 0.1 part of compound probiotic liquid. The compound probiotic liquid wherein is mixed by Bacillus licheniformis bacterial liquid, Lactobacillus casei bacterial liquid and Saccharomyces cerevisiae bacterial liquid, and the parts of three kinds of bacterial liquids by weight are respectively 25 parts of Bacillus licheniformis bacterial liquids, cheese milk 40 parts of Bacillus bacteria liquid and 35 parts of Saccharomyces cerevisiae bacteria liquid. The bacterial contents of the three bacterial solutions are respectively: the bacterial contents of the Bacillus licheniformis bacterial solution ≥ 1.0×10 10 cfu / mL, the bacterial content of Lactobacillus casei ≥ 5.0×10 11 cfu / mL, the bacterial content of Saccharomyces cerevisiae liquid ≥4.0×10 8 cfu / mL. The straw decomposing agent wherein is mi...

Embodiment 2

[0036] The raw materials of the bio-organic fertilizer in this embodiment include 63 parts by weight of animal manure and urine, 30 parts of straw, 0.2 part of straw decomposing agent and 0.14 part of compound probiotic liquid. The compound probiotic liquid wherein is mixed by Bacillus licheniformis bacterial liquid, Lactobacillus casei bacterial liquid and Saccharomyces cerevisiae bacterial liquid, and the parts of three kinds of bacterial liquids by weight are respectively 30 parts of Bacillus licheniformis bacterial liquids, cheese milk 45 parts of Bacillus bacteria liquid and 29 parts of Saccharomyces cerevisiae bacteria liquid. The bacterial contents of the three bacterial solutions are respectively: the bacterial contents of the Bacillus licheniformis bacterial solution ≥ 1.0×10 10 cfu / mL, the bacterial content of Lactobacillus casei ≥ 5.0×10 11 cfu / mL, the bacterial content of Saccharomyces cerevisiae liquid ≥4.0×10 8 cfu / mL. The straw decomposing agent wherein is mi...

Embodiment 3

[0042] The raw materials of the bio-organic fertilizer in this embodiment include 67 parts by weight of animal excrement and urine, 40 parts of straw, 0.3 part of straw decomposing agent and 0.18 part of compound probiotic liquid. The compound probiotic liquid wherein is mixed by Bacillus licheniformis bacterial liquid, Lactobacillus casei bacterial liquid and Saccharomyces cerevisiae bacterial liquid, and the parts of three kinds of bacterial liquids by weight are respectively 35 parts of Bacillus licheniformis bacterial liquids, cheese milk 37 parts of Bacillus bacteria liquid and 25 parts of Saccharomyces cerevisiae bacteria liquid. The bacterial contents of the three bacterial solutions are respectively: the bacterial contents of the Bacillus licheniformis bacterial solution ≥ 1.0×10 10 cfu / mL, the bacterial content of Lactobacillus casei ≥ 5.0×10 11 cfu / mL, the bacterial content of Saccharomyces cerevisiae liquid ≥4.0×10 8 cfu / mL. The straw decomposing agent wherein is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com