Preparation method of two-dimensional In2S3/SnS heterojunction crystal material

A crystalline and heterogeneous technology, applied in the field of preparation of two-dimensional In2S3/SnS heterogeneous crystalline materials, can solve the problems of complex reaction process, destruction of product structure and properties, complicated synthesis process, etc., to achieve high crystal quality and reduce energy consumption. , the effect of reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

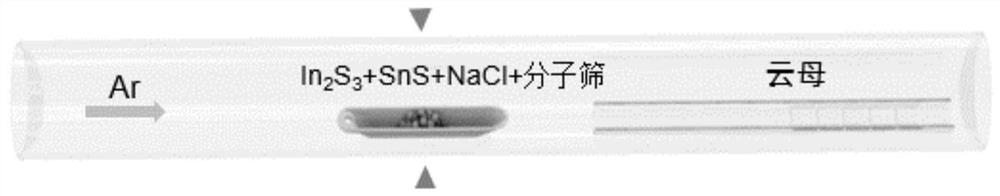

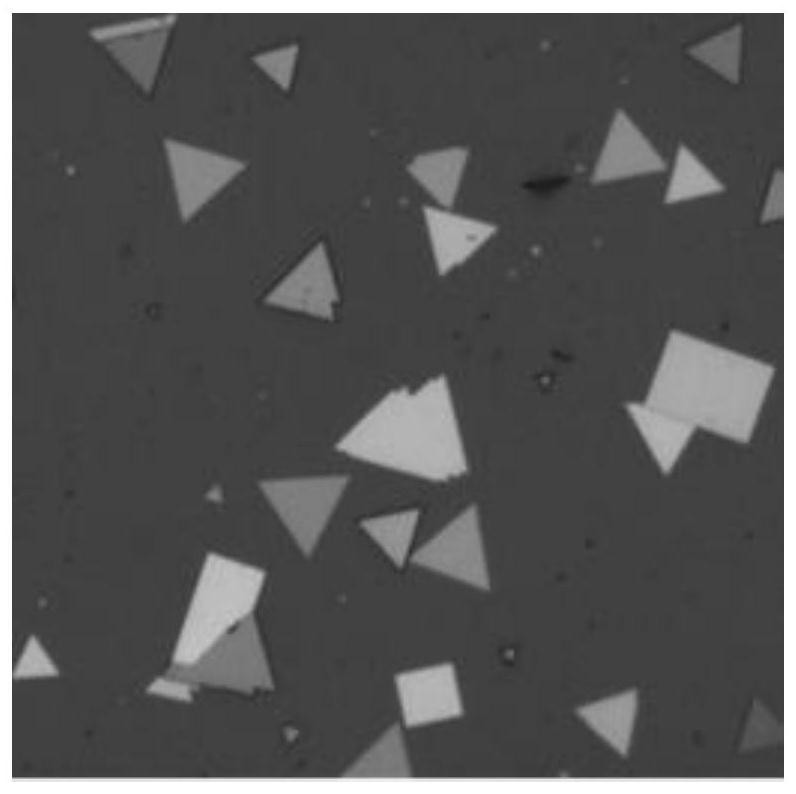

Embodiment 1

[0030] A horizontal tube furnace with a single temperature zone is used as the reaction device. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, and the temperature of the central temperature zone (corresponding to the center of the furnace) is 830°C , the temperature in the downstream deposition area is 600°C, and the heating method is rapid heating (in advance, the tube slide rail furnace is heated to the specified reaction temperature in the non-reaction area, and then the furnace is quickly moved to the reaction area for rapid temperature increase). Using In 2 S 3 and SnS powder (purity>99.99%) as In 2 S 3 and SnS source, adding NaCl at the same time to obtain the precursor (in the precursor, the mass ratio of indium sulfide to tin sulfide is 2:1), and at the same time, the molecular sieve is placed above the precursor and placed in the central temperatu...

Embodiment 2

[0034] A horizontal tube furnace with a single temperature zone is used as the reaction device. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, the temperature in the central temperature zone is 820°C, and the temperature in the downstream deposition zone The temperature is 600°C, and the heating method is rapid heating (in advance, the tube slide rail furnace is heated to the specified reaction temperature in the non-reaction area, and then the furnace is quickly moved to the reaction area for rapid temperature increase). Using In 2 S 3 and SnS powder (purity>99.99%) as In 2 S 3 and SnS source, adding NaCl at the same time to obtain a precursor (in the precursor, the mass ratio of indium sulfide to tin sulfide is 2:1), and at the same time, molecular sieves are placed above the precursor and placed in the central temperature zone; A 1cm*1cm piece of fluor...

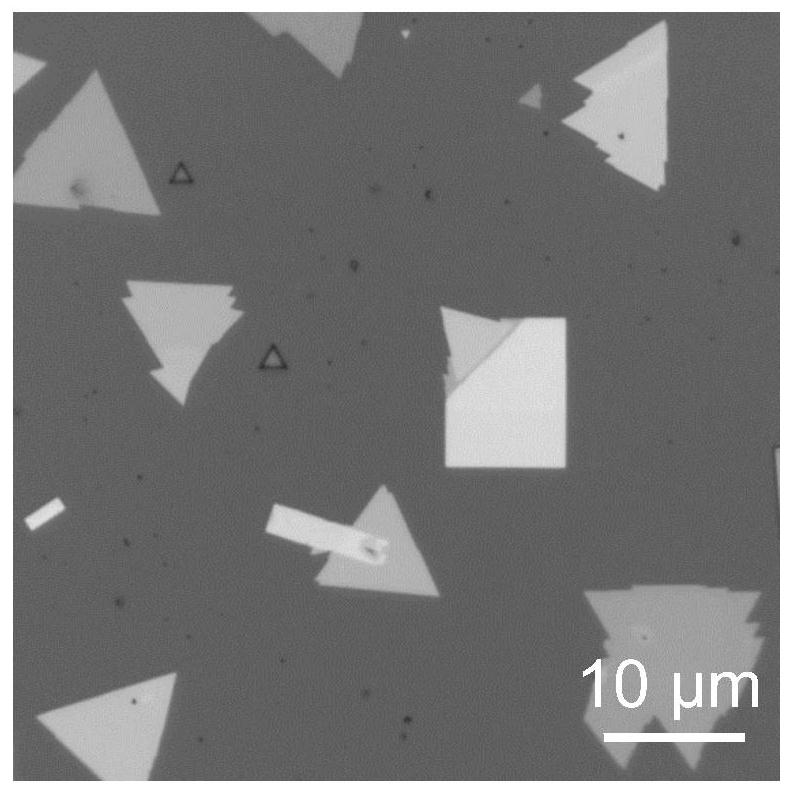

Embodiment 3

[0036] A horizontal tube furnace with a single temperature zone is used as the reaction device. The tube length of the horizontal tube furnace is 90cm, the outer diameter is 25mm, the tube wall thickness is 2mm, the range of the constant temperature zone is 10cm, the temperature in the central temperature zone is 850°C, and the temperature in the downstream deposition zone The temperature is 600°C, and the heating method is rapid heating (in advance, the tube slide rail furnace is heated to the specified reaction temperature in the non-reaction area, and then the furnace is quickly moved to the reaction area for rapid temperature increase). Using In 2 S 3 and SnS powder (purity>99.99%) as In 2 S 3 and SnS source, adding NaCl at the same time to obtain a precursor (in the precursor, the mass ratio of indium sulfide to tin sulfide is 2:1), and at the same time, molecular sieves are placed above the precursor and placed in the central temperature zone; A 1cm*1cm piece of fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com