Silicon-carbon composite material, preparation method and application thereof, electrode and lithium ion battery,

A silicon-carbon composite material, lithium carbonate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of the cycle performance and rate performance of silicon-based anode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

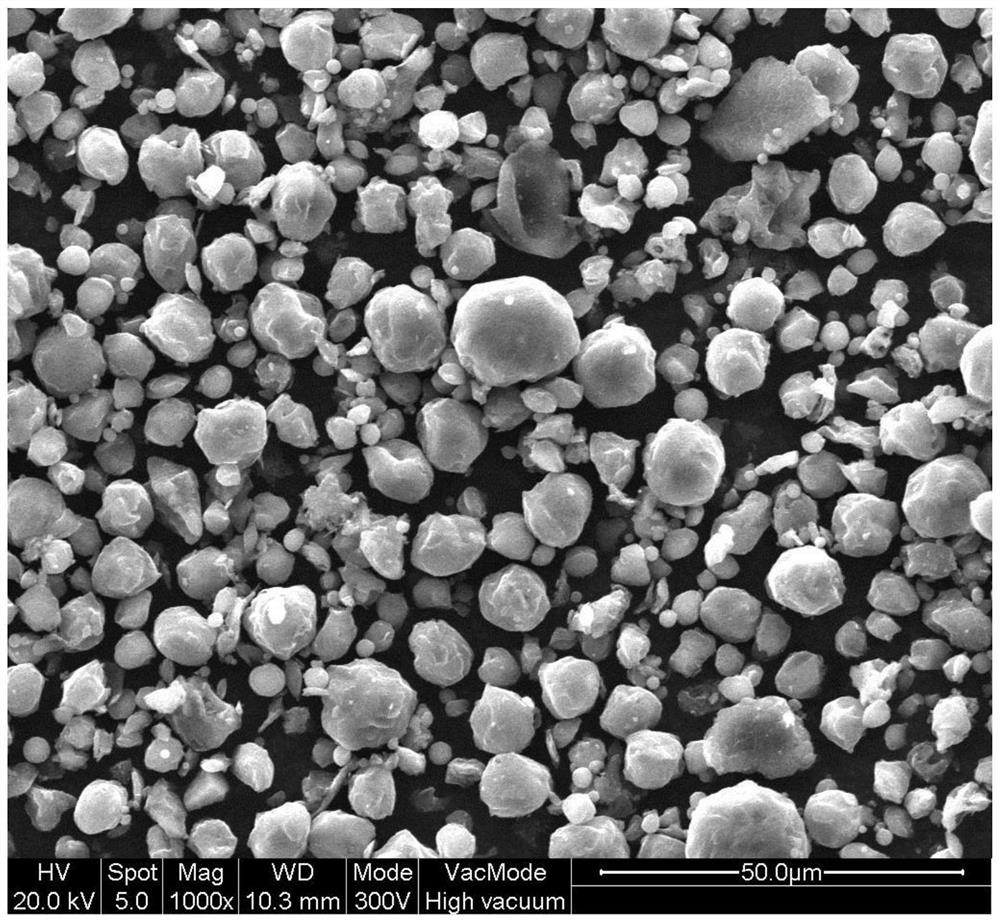

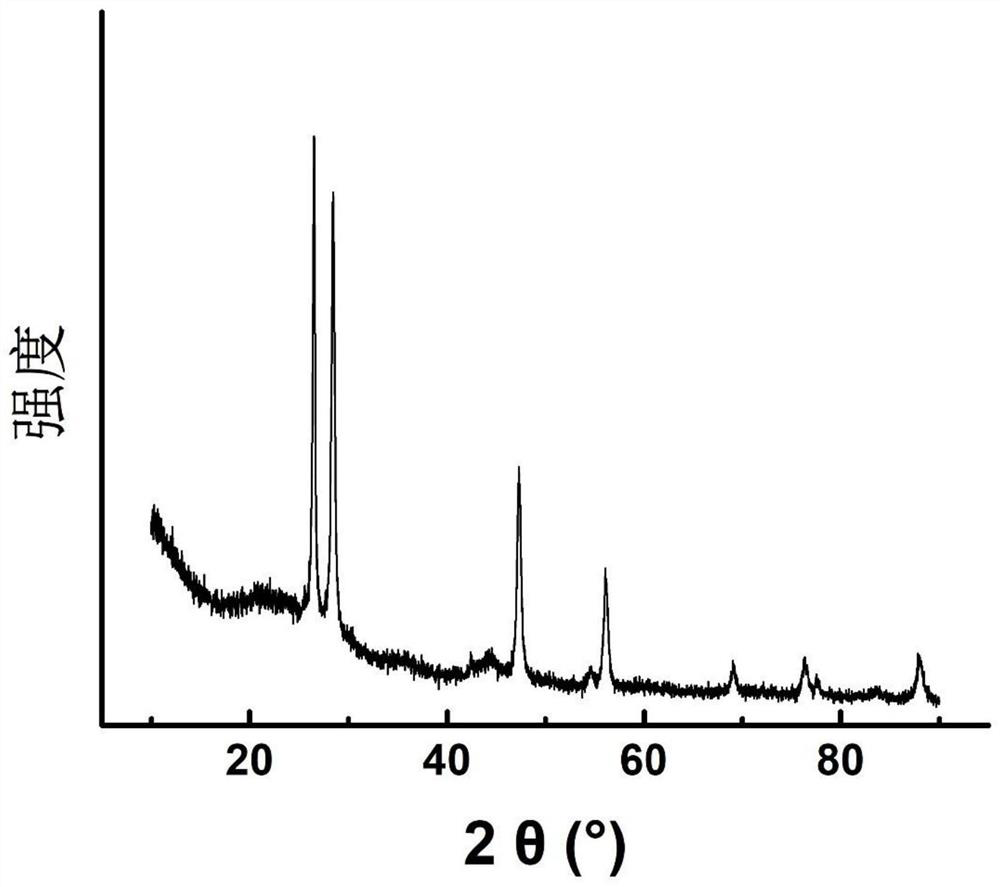

[0081] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0082] S1. The solvent is NMP-ethanol mixed solvent with a ratio of 10:90. According to 900 parts of solvents, 100 parts of silicon, 3 parts of lithium carbonate, 0.03 parts of single-walled carbon nanotube-NMP slurry (calculated by carbon nanotubes) and 50 parts of flake graphite powder, stir in a high-speed disperser for 0.5 hours;

[0083] Then transfer to the pin-rod type dynamic separation high-energy sand mill for sand grinding. The sand mill adopts yttrium oxide stabilized zirconia balls with a diameter of 0.5mm, and the speed adopts 98% of the design speed of the equipment, and the sand mill is continuous for 2 hours;

[0084] Then add 100 parts of novolac resin, 9 parts of hexamethylenetetramine, 8 parts of PVA 1788, 5 parts of PVP K30, and sand again for 2 hours to obtain a sand-milled homogeneous slurry;

[0085] Finally, the slurry was transferred to an ultrasonic machine...

Embodiment 2

[0090] Except adding 5 parts of lithium carbonate and 0.1 part of single-walled carbon nanotube-NMP slurry (calculated as carbon nanotubes) in step S1, other steps and conditions were the same as in Example 1.

Embodiment 3

[0092] A method for preparing a silicon-carbon composite material, comprising the steps of:

[0093] S1. The solvent is NMP-ethanol mixed solvent with a ratio of 10:90. According to 900 parts of solvents, 100 parts of silicon, 5 parts of lithium carbonate, 0.03 parts of single-walled carbon nanotube-NMP slurry (in terms of carbon nanotubes) and 10 parts of flake graphite powder, stir in a high-speed disperser for 0.5 hours;

[0094] Then transfer to the pin-rod type dynamic separation high-energy sand mill for sand grinding. The sand mill adopts yttrium oxide stabilized zirconia balls with a diameter of 0.5mm, and the speed adopts 98% of the design speed of the equipment, and the sand mill is continuous for 2 hours;

[0095] Then add 40 parts of flake graphite powder, 100 parts of novolac resin, 9 parts of hexamethylenetetramine, 8 parts of PVA 1788, 5 parts of PVP K30, and sand mill for 1 hour to obtain sand mill homogeneous slurry;

[0096] Finally, the slurry was transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com