A highly dispersed magnetic nano photocatalyst and its preparation method

A nano-photocatalyst, high-dispersion technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve secondary pollution, low photocatalytic activity, high photogenerated hole-electron recombination rate, etc. problems, to achieve the effect of high dispersion in water phase, simple control steps and low reagent cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

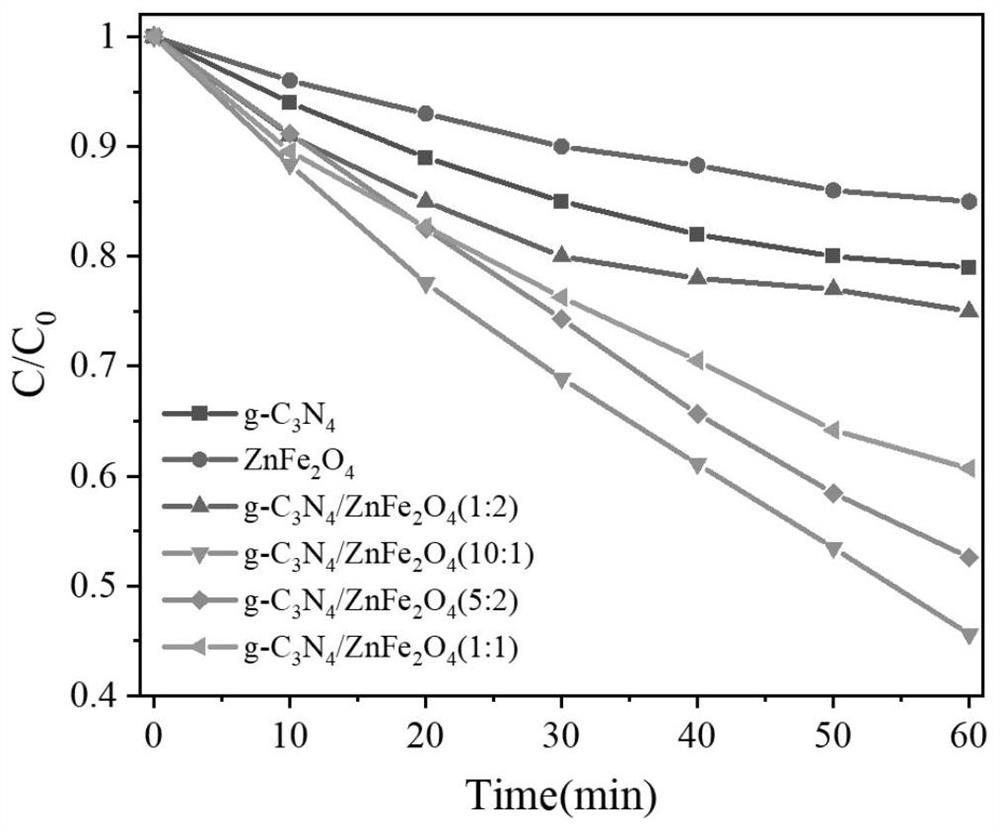

[0045] Synthetic g-C 3 N 4 / ZnFe 2 o 4 (10:1) nano catalyst (g-C in step (2) 3 N 4 with ZnFe 2 o 4 The mass ratio is 10:1).

[0046] Specific steps are as follows:

[0047] (1) Preparation of g-C by calcination 3 N 4 Powder: CH 4 N 2O (urea) was placed in a muffle furnace, heated to 550°C at a rate of 2.5°C / min, and calcined for 4 hours to obtain g-C 3 N 4 powder.

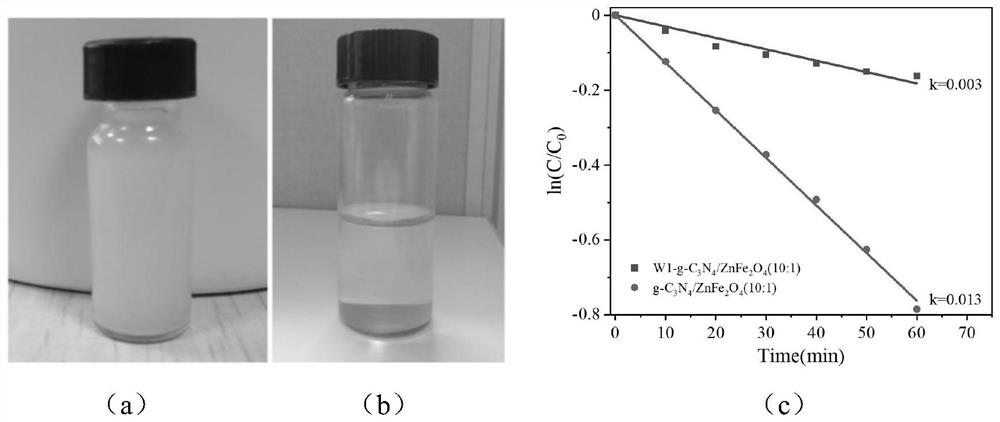

[0048] (2) Preparation of precursor solution: first, add the g-C obtained in step (1) to water 3 N 4 powder, and stirred and mixed, and then ultrasonicated at 400W for 30 minutes to obtain a uniformly dispersed suspension A. After the suspension stood for 12 hours, g-C 3 N 4 Still uniformly dispersed in water, g-C in suspension A 3 N 4 The concentration is 6g / L. Secondly, Fe(NO 3 ) 3 9H 2 O and Zn(NO 3 ) 2 ·6H 2 O, stirred to form solution B, Fe in solution B 3+ The concentration is 2.50mmol / L, Zn 2+ The concentration is 1.25mmol / L. Finally, solution B was added dropwise at a rate of 0....

Embodiment 2

[0052] Synthetic g-C 3 N 4 / ZnFe 2 o 4 (5:2) nano catalyst (g-C in step (2) 3 N 4 with ZnFe 2 o 4 The mass ratio is 5:2).

[0053] Specific steps are as follows:

[0054] (1) Preparation of g-C by calcination 3 N 4 Powder: CH 4 N 2 O (urea) is placed in a muffle furnace, heated to 500°C at a rate of 4°C / min, and calcined for 2 hours to obtain g-C 3 N 4 powder.

[0055] (2) Preparation of precursor solution: first, add the g-C obtained in step (1) to water 3 N 4 Powder, and stir to mix, and then ultrasonic 60min under 400W power to obtain a uniformly dispersed suspension A, after the suspension stood for 12h g-C 3 N 4 Still uniformly dispersed in water, g-C in suspension A 3 N 4 The concentration is 5g / L. Secondly, Fe(NO 3 ) 3 9H 2 O and Zn(NO 3 ) 2 ·6H 2 O, stirred to form solution B, Fe in solution B 3+ The concentration is 10.00mmol / L, Zn 2+ The concentration is 5.00mmol / L. Finally, solution B was added dropwise at a rate of 0.2ml / s to the contin...

Embodiment 3

[0059] Synthetic g-C 3 N 4 / ZnFe 2 o 4 (1:1) nano catalyst (g-C in step (2) 3 N 4 with ZnFe 2 o 4 The mass ratio is 1:1).

[0060] Specific steps are as follows:

[0061] (1) Preparation of g-C by calcination 3 N 4 Powder: CH 4 N 2 O (urea) is placed in a muffle furnace, heated to 530°C at a rate of 3°C / min, and calcined for 3 hours to obtain g-C 3 N 4 powder.

[0062] (2) Prepare the precursor solution: first, add the g-C obtained in (1) to water 3 N 4 powder, and stirred and mixed, and then ultrasonicated at 400W for 90 minutes to obtain a uniformly dispersed suspension A. After the suspension stood for 12 hours, g-C 3 N 4 Still uniformly dispersed in water, g-C in suspension A 3 N 4 The concentration is 4g / L. Secondly, the ratio of the amount of substances added to water is 2:1 C 15 h 21 FeO 6 and Zn(CH 3 COO) 2 , stirred to form solution B, Fe in solution B 3+ The concentration is 50.00mmol / L, Zn 2+ The concentration is 25.00mmol / L. Finally, sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com