Permanent magnet ferrite magnetic tile with high structural strength and preparation method thereof

A technology of permanent magnet ferrite and high structure, which is applied in the direction of inductance/transformer/magnet manufacturing, inorganic material magnetism, circuits, etc. It can solve the problems of magnetic tile reduction, achieve the effect of increasing density, improving fluidity, and increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

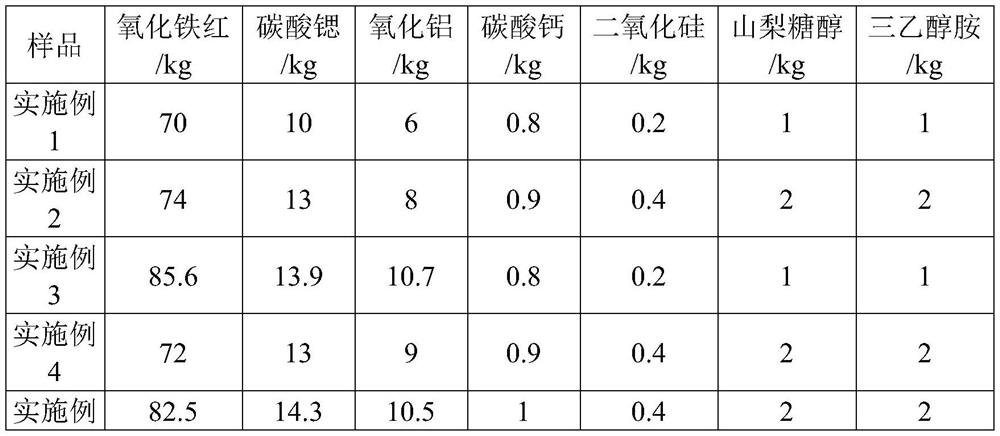

[0055] As shown in Table 1, the main difference between Examples 1 to 8 lies in the ratio of raw materials.

Embodiment 1

[0057] The preparation method of the permanent magnet ferrite magnetic tile of embodiment 1 is as follows:

[0058] S1. take iron oxide red, strontium carbonate, alumina, calcium carbonate and silicon dioxide, ball mill 10h to obtain slurry 1;

[0059] S2. add sorbitol to the slurry 1, stir at 60r / min for 15min;

[0060] S3. add triethanolamine, stir at 60r / min for 30min, settle to a water content of 15%, and obtain a settled slurry;

[0061] S4. Inject the sedimentation slurry into the cemented carbide runner mold, and use a 150-ton automatic hydraulic press to press the sedimentation slurry into green embryos; place the green embryos in a sintering electric kiln for sintering, and control the temperature to 1200 ° C for 3 hours; after cooling Obtain permanent magnet ferrite tiles.

[0062] Among them, the heating rate is 3 ℃ / min; the specification of the steel ball is Φ6.35mm.

[0063] Table 1

[0064]

[0065]

Embodiment 9~14

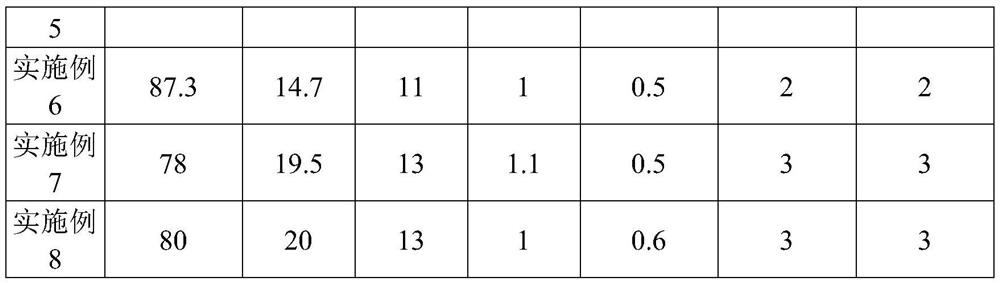

[0067] Compared with Example 5, the difference between Examples 9 to 14 is that the formula also contains zirconium oxynitrate dihydrate and a hydrolysis accelerator.

[0068] As shown in Table 2, the main difference between Examples 9 to 14 is the ratio of raw materials.

[0069] Example 9 is taken as an example for description below.

[0070] S1. Weigh iron oxide red, strontium carbonate, alumina, calcium carbonate and silicon dioxide, after ball milling for 10h, add zirconium oxynitrate dihydrate and a hydrolysis accelerator, mix at 50r / min for 30min to obtain slurry 1

[0071] S2. Add sorbitol to slurry 2, stir at 60r / min for 15min;

[0072] S3. add triethanolamine, stir at 60r / min for 30min, settle to a water content of 15%, and obtain a settled slurry;

[0073] S4. Inject the sedimentation slurry into the cemented carbide runner mold, and use a 150-ton automatic hydraulic press to press the sedimentation slurry into green embryos; place the green embryos in a sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com