Super-early-strength polycarboxylate-type water reducing agent as well as preparation method and application thereof

A polycarboxylate-based, ultra-early-strength type technology, applied in the field of polycarboxylate-based water reducers, can solve problems such as slow strength development, achieve high early strength, good slump retention, and promote the effect of cement hydration reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

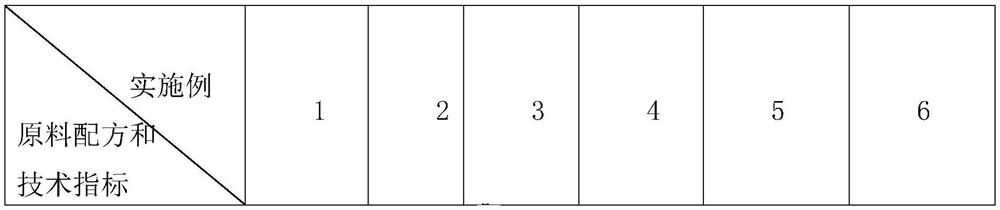

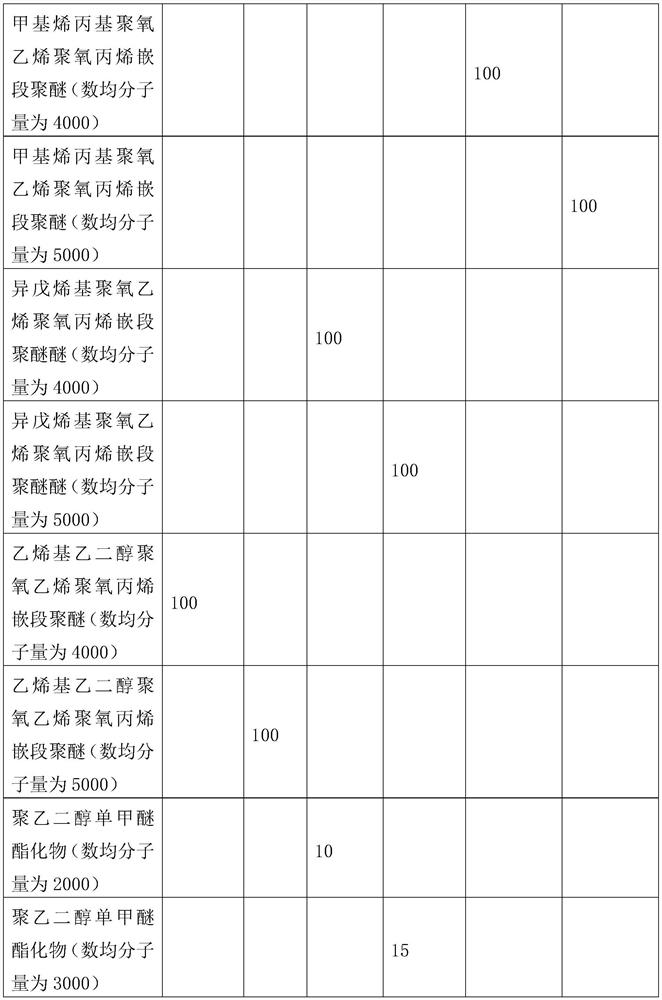

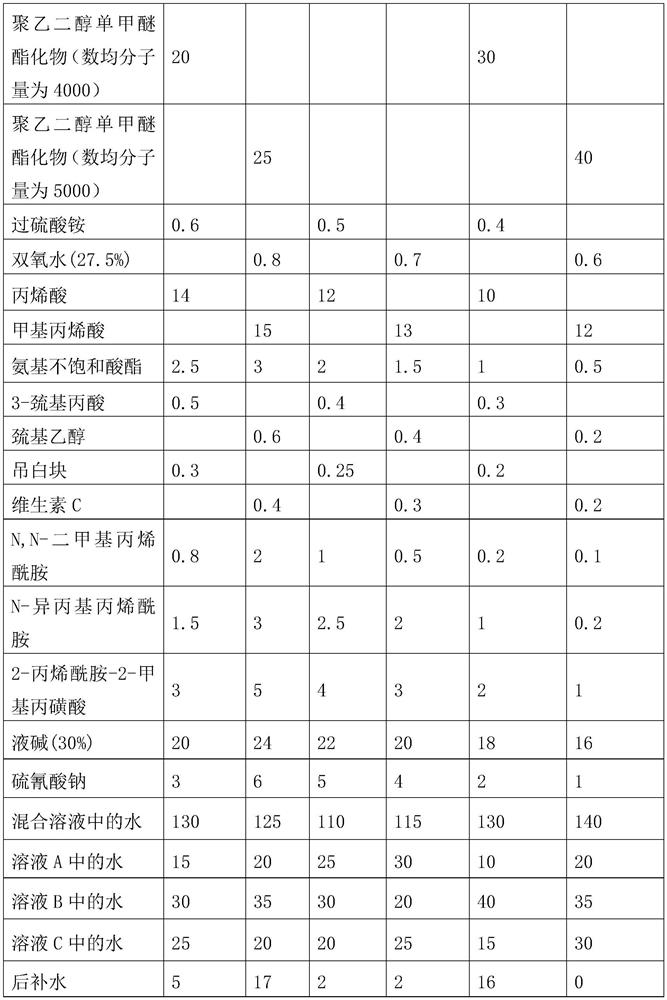

[0048] In the first aspect, the present application provides a method for preparing a super-early-strength polycarboxylate water reducer, the preparation method comprising: in the presence of an oxidizing agent, a reducing agent and a chain transfer agent, including unsaturated polyoxygen Ethylene polyoxypropylene block amine ether, polyethylene glycol monomethyl ether ester, unsaturated monocarboxylic acid, amino unsaturated ester, N,N-dimethylacrylamide, N-isopropylacrylamide and 2 -The monomer mixture of acrylamide-2-methylpropanesulfonic acid undergoes free radical polymerization reaction, and then adds liquid caustic soda for neutralization, and then adds thiocyanate to obtain the super-early-strength polycarboxylate water-reducing agent.

[0049] In one embodiment, based on parts by weight, the super early strength polycarboxylate water reducer is made of the following raw material components: 100 parts of unsaturated polyoxyethylene polyoxypropylene block amine Ether, ...

Embodiment 1

[0081] A preparation method of super-early-strength polycarboxylate water-reducer, comprising the steps of:

[0082] (1) Preparation before polymerization: 100 parts of ethylene glycol polyoxyethylene polyoxypropylene block polyether with a number average molecular weight of 4000, 20 parts of polyethylene glycol monomethyl ether esterified with a number average molecular weight of 4000 and 120 parts of water parts by weight, put it into a reaction container, heat up to 30°C, stir fully to completely dissolve the solid and mix evenly to obtain the first mixed solution;

[0083] Preparation of solution A: Accurately weigh 14 parts by weight of acrylic acid, 2.5 parts by weight of amino unsaturated ester, 0.5 parts by weight of mercaptopropionic acid and 15 parts by weight of water, stir and mix evenly and pump into high tank A for dripping;

[0084] Preparation of solution B: Accurately weigh 0.3 parts by weight of hanging white block (alias: sodium formaldehyde sulfoxylate, model...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com