Preparation method of multilayer electronic product

A technology for electronic products and insulating layers, which is applied in the field of preparation of multilayer electronic products, and can solve the problems of inability to achieve integration, low production efficiency, and inability to apply industrially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

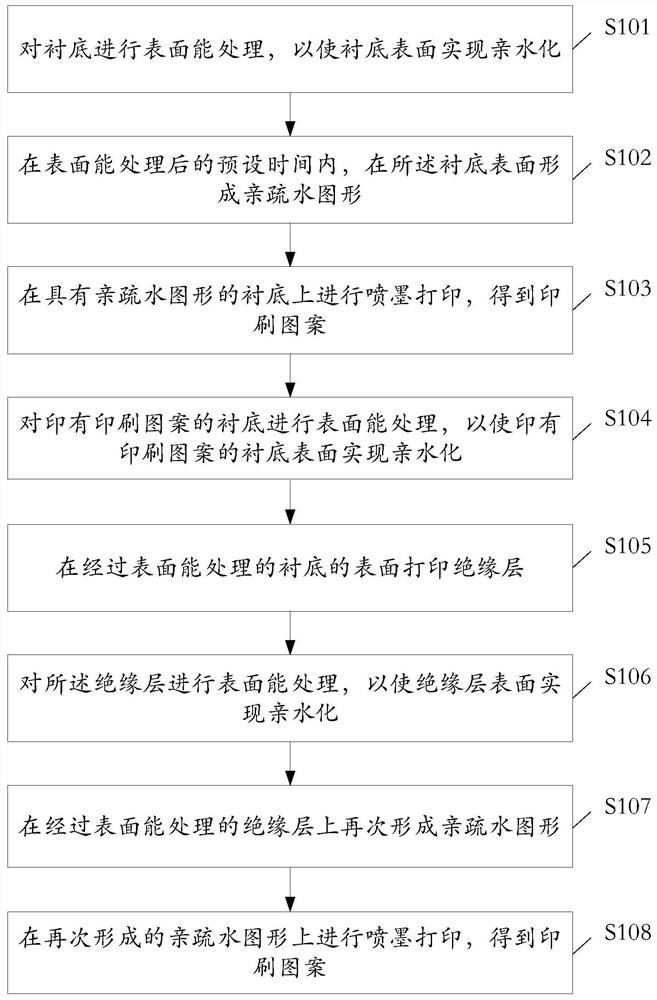

[0065]Such asfigure 1 As shown, the present invention provides a method of preparing a multilayer electronic product, including:

[0066]S101, the substrate can be processed so that the surface of the substrate is hydrophilized;

[0067]The substrate of the present invention needs to be performed in advance, the surface energy treatment is preferably a strong oxidation treatment, and the specific process includes cleaning the substrate; drying the substrate after the cleaning; At least one of the ozone treatment, oxygen or oxidation, ionic treatment, and ultraviolet light treatment, and the Si-O- (H) group of the substrate surface.

[0068]Specifically, when the strong oxidation treatment is ozone treatment, it has the advantages of simple and convenient, high-quality equipment.

[0069]Specifically, when the strong oxidation is treated with an oxygen or oxygen, a vacuum plasma and an atmospheric plasma treatment (generally also referred to as corona treatment). Vacuum plasma needs to evacuate,...

Embodiment 1

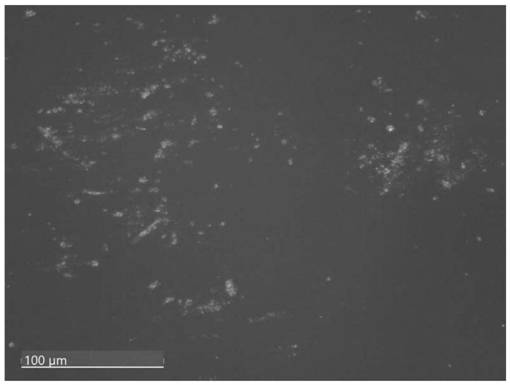

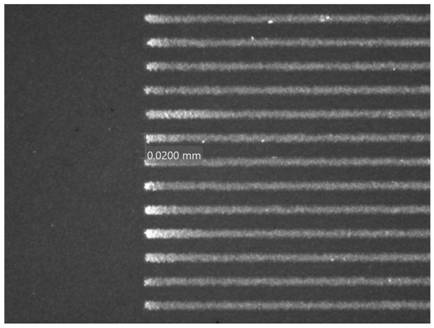

[0158](1) The glass is used as a substrate, and the substrate is performed by highly active ozone components produced by the ultraviolet cleaning machine for 5-50 minutes (preferably 30 minutes), so that the surface of the substrate is active Si- O- (h) group;

[0159](2) The seal made of silicone rubber containing the -O-Si-R group is selected from the seal of the polydimethylsiloxane;

[0160](3) In 1s after the end of the strong oxidation treatment, the printed roller of the seal is fixed to the substrate surface of the Si-O- (H) group, and the contact pressure is limited to around 1000Pa. . The roller pressure is 50 mm / s, and the width of 50 microns in accordance with the printing roller and the plane contact region is estimated, the average contact time of the seal and the substrate surface is substantially 1 ms. The water contact angle of the substrate is made from about 15 ° C to about 70 ° C;

[0161]The seal is separated from a substrate with a Si-O- (H) group to obtain a rocket p...

Embodiment 2

[0170](1) The glass is used as a substrate, and the substrate is treated with a spray gun treated with a normal pressure plasma, and the average treatment time is 3-5 s, so that the substrate is formed to form an active Si-O- (H) group;

[0171](2) The seal made of silicone rubber containing the -O-Si-R group is made of methyl vinyl silicone rubber.

[0172](3) In 30s after strong oxidation treatment, the printed roller of the stamp is fixed to the substrate surface of the Si-O- (H) group, and the contact pressure is limited to about 2000 Pa. The roller pressure velocity is 5 mm / s, which is estimated according to the width of the printed roller and the planar contact region, and the average contact time of the seal and the substrate surface is substantially 10 ms, which causes the water contact angle of the substrate from about 20 ° C to About 75 ° C;

[0173]The seal is separated from a substrate with a Si-O- (H) group to obtain a rocket pattern;

[0174](4) The ink containing the conductive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com