Structure and preparation method of MOSFET device based on diamond substrate

A diamond and single crystal diamond technology, applied in the field of microelectronics, can solve the problems of the maximum saturation current device switching ratio output resistance, insufficient cut-off frequency, the advantages of diamond-based devices are not fully reflected, and the quality of diamond materials is not enough, etc. Simple process, excellent pinch-off characteristics, high breakdown voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

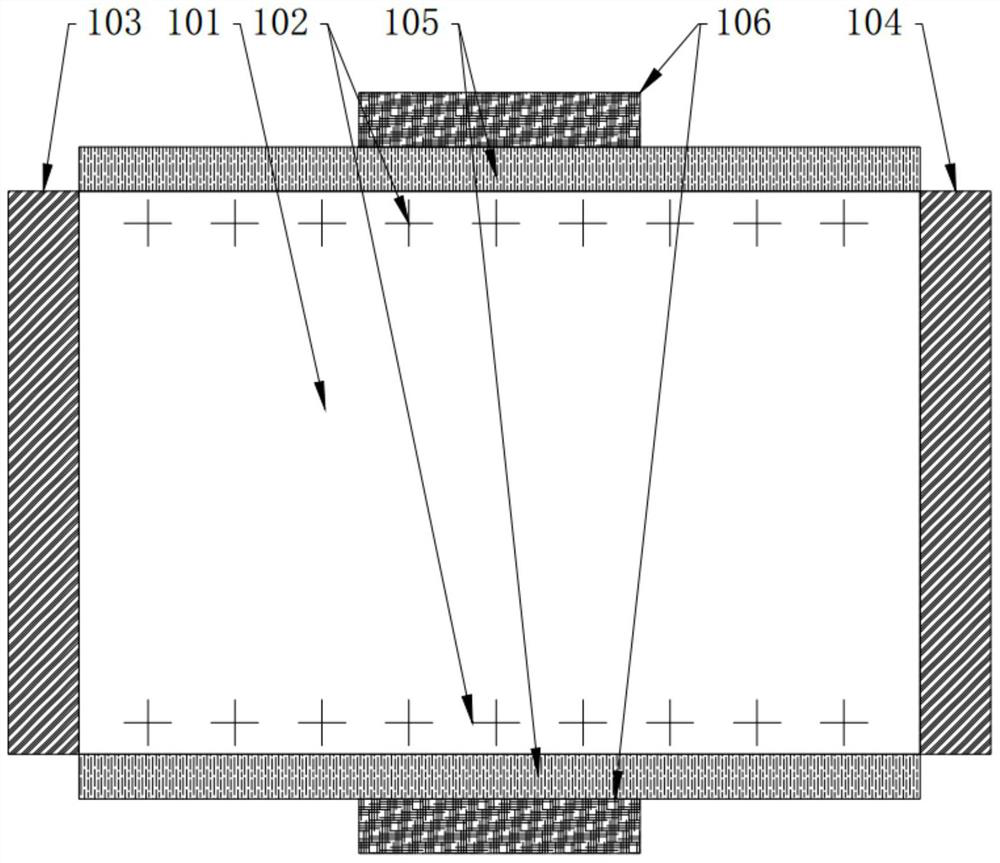

[0035] S1: Using a colorless single crystal diamond 101 grown by MPCVD as a substrate, at a temperature of 850° C., expose the upper and lower surfaces of the diamond substrate 101 to hydrogen plasma for 10 minutes to form a hydrogen terminal layer 102, and the hydrogen flow rate is 500 sccm;

[0036] S2: On both sides of the diamond substrate 101 with the hydrogen terminal layer 102, deposit a layer of Au with a thickness of 100 nm by electron beam evaporation, and form an ohmic contact with the surface of the diamond substrate as a source electrode and a drain electrode;

[0037] S3: Deposit 4nm-thick Al on the upper and lower surfaces of the sample obtained in the previous step, and then anneal at 80°C for 30min to form 5nm-thick Al 2 o 3 As a gate dielectric layer;

[0038] S4: Finally, 100 nm of Al is deposited on the surface of the gate dielectric layer, and the gate electrode is formed by peeling off to complete the preparation of the device.

Embodiment 2

[0040] S1: using colorless single crystal diamond grown by MPCVD as a substrate, at a temperature of 700-900°C, exposing the upper and lower surfaces of the diamond substrate 101 to hydrogen plasma for 5 minutes to form a hydrogen terminal layer 102, and the hydrogen flow rate is 450 sccm;

[0041] S2: On both sides of the diamond substrate 101 with the hydrogen terminal layer 102, deposit a layer of Au with a thickness of 50 nm by electron beam evaporation, and form an ohmic contact with the surface of the diamond substrate 101 as the source electrode 103 and the drain electrode 104;

[0042] S3: Deposit 4nm-thick Al on the upper and lower surfaces of the sample obtained in the previous step, and then anneal at 70-90°C for 25min to form 3nm-thick Al 2 o 3 As a gate dielectric layer 105;

[0043] S4: Finally, 90 nm of Al is deposited on the surface of the gate dielectric layer 105, and the gate electrode 106 is formed by peeling off to complete the preparation of the device. ...

Embodiment 3

[0045] S1: Using colorless single crystal diamond grown by MPCVD as the substrate, at a temperature of 900° C., the upper and lower surfaces of the diamond substrate 101 were exposed to hydrogen plasma for 15 minutes to form a hydrogen terminal layer 102, and the hydrogen flow rate was 550 sccm;

[0046] S2: On both sides of the diamond substrate 101 with the hydrogen termination layer 102, a layer of Au with a thickness of 150 nm is deposited by electron beam evaporation to form an ohmic contact with the surface of the diamond substrate 101 as the source electrode 103 and the drain electrode 104;

[0047] S3: Deposit 4nm-thick Al on the upper and lower surfaces of the sample obtained in the previous step, and then anneal at 90°C for 35min to form 10nm-thick Al 2 o 3 As a gate dielectric layer 105;

[0048] S4: Finally, 110 nm of Al is deposited on the surface of the gate dielectric layer 105, and the gate electrode 106 is formed by peeling off to complete the preparation of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com