Preparation method of vacuum low-temperature fried allium victorialis crisp chips

A technology of vacuum low-temperature frying and shallots, which is applied in the forming of food, the function of food ingredients, food preservation, etc., can solve the problems of the onion planting industry that cannot meet the needs, the market conditions are affected by foreign countries, and the market risks are large, and achieve Effects of increasing cell permeability, shortening frying time, and prolonging commodity shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

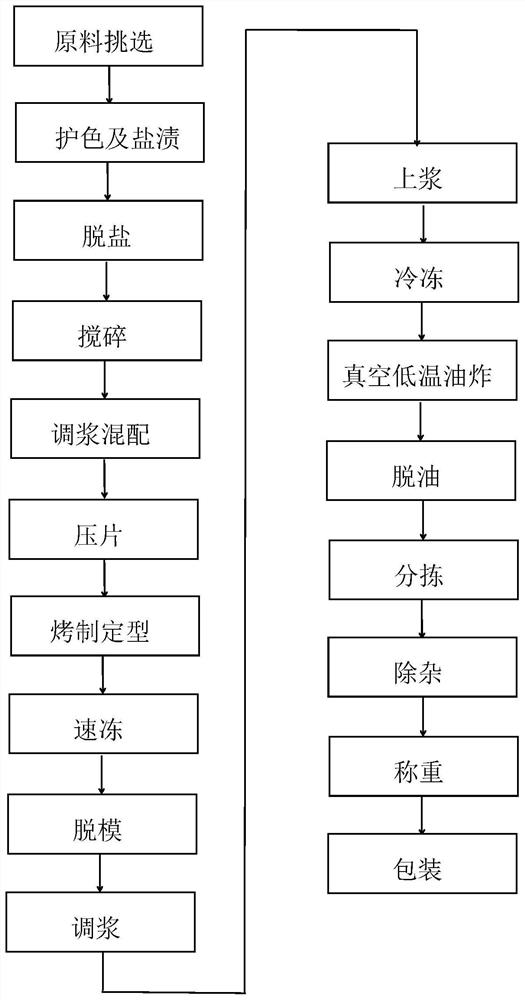

[0045] Such as figure 1 As shown, it is a flow chart of a preparation method of vacuum low-temperature deep-fried shallot chips of the present invention, which includes steps: raw material selection → color protection and salting → desalination → crushing → pulp mixing → sheeting → roasting Formulating→Quick freezing→Demolding→Mulching→Sizing→Freezing→Vacuum low-temperature frying→Deoiling→Sorting→Impurity removal→Weighing→Packaging. The specific steps are as follows:

[0046] S1: Selection of raw materials

[0047] Select fresh and tender raw materials, remove yellowed, diseased, moth-eaten, and inedible parts; rinse the selected allium scallion leaves with clean water, classify them according to the size of the leaves, and bundle them into bundles with a thickness of 8-10cm.

[0048] S2: Color protection and salt staining

[0049] Soak the shallot leaves in an aqueous solution containing 0.8-1.2% NaCl and 0.05-0.15% citric acid for 15-30 minutes, perform color protection ...

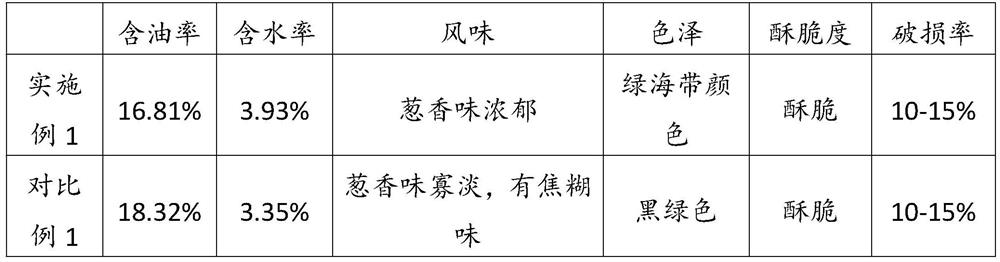

Embodiment 1

[0081] The invention provides a sesame-flavored scallion crisp, the preparation process of which is as follows:

[0082] (1) Selection of raw materials: select fresh and tender raw materials, and remove non-edible parts such as yellowing, diseased spots and moths. Rinse the selected allium scallion leaves with clean water, sort and bundle them into bundles according to the size and specifications of the leaves, and the thickness of the bundles is 10cm.

[0083] (2) Salting and color protection: put the processed leaves of the onion into 1% NaCl, 0.1% citric acid to prepare a color protection solution, and soak for 20 minutes. Then, the leaves of the onion are salted by using the salt water soaking method, the salt water concentration is 10%, and the salt soaking time is 24 hours.

[0084] (3) Desalination: put the salted onion onion in 1% light salt water, the mass ratio of water to raw material is 4:1, desalinate for more than 2 hours, and then take it out and drain the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com