A preparation method for 3D printing femoral head with customizable regenerative porous nanomaterials

A technology of nanomaterials and femoral heads, applied in 3D printing, femoral heads, manufacturing tools, etc., can solve the problems of stimulating repair and growth, low utilization rate of artificial bone components, insufficient toughness and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

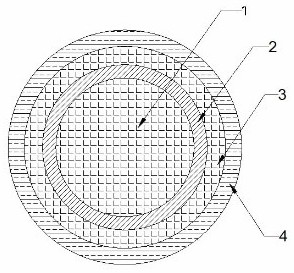

Image

Examples

Embodiment Construction

[0040] Step 1: Use CT scanning equipment to perform three-dimensional scanning of the damaged hip joint and femoral head of the hip joint to obtain image data. Based on the damaged hip joint femoral head, use three-dimensional software to redesign the size and shape of the hip joint femoral head that can be transplanted.

[0041] The second step: take Ti powder (purity is 99.9%), Mg particles (purity is 99.8%), Si particles (purity is 99.8%), Ca particles, Mo powder molar ratio is (30-50): (15- 25): (30-40): (10-20): (0.1-0.3) After mixing evenly, put it into a high-energy ball mill for processing to obtain ultrafine composite powder with a grain size of 80-100nm.

[0042] Step 3: Mix deionized water, sodium polyacrylate, β-tricalcium phosphate, hydroxymethyl propylene, and cellulose in the mass fraction ratio of (1-1.2): (0.8-1): (2-5): (1 -1.5): (1.2-1.6) Mix and put into a closed container, add equal volume of 0.1mol / L pyrrole and 0.2mol / L polyferric chloride, mix and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com