A multi-stage serial filtration system composed of a porous ceramic filter and its preparation method

A filtration system, porous ceramic technology, applied in ceramic products, chemical instruments and methods, filtration treatment, etc., can solve the problems of high price, low cost, inability to effectively remove heavy metals from water, etc., achieve large specific surface area, and enhance inactivation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

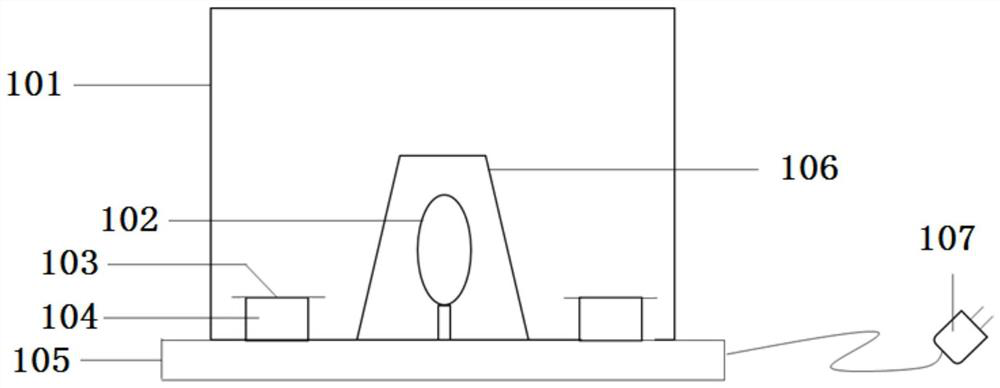

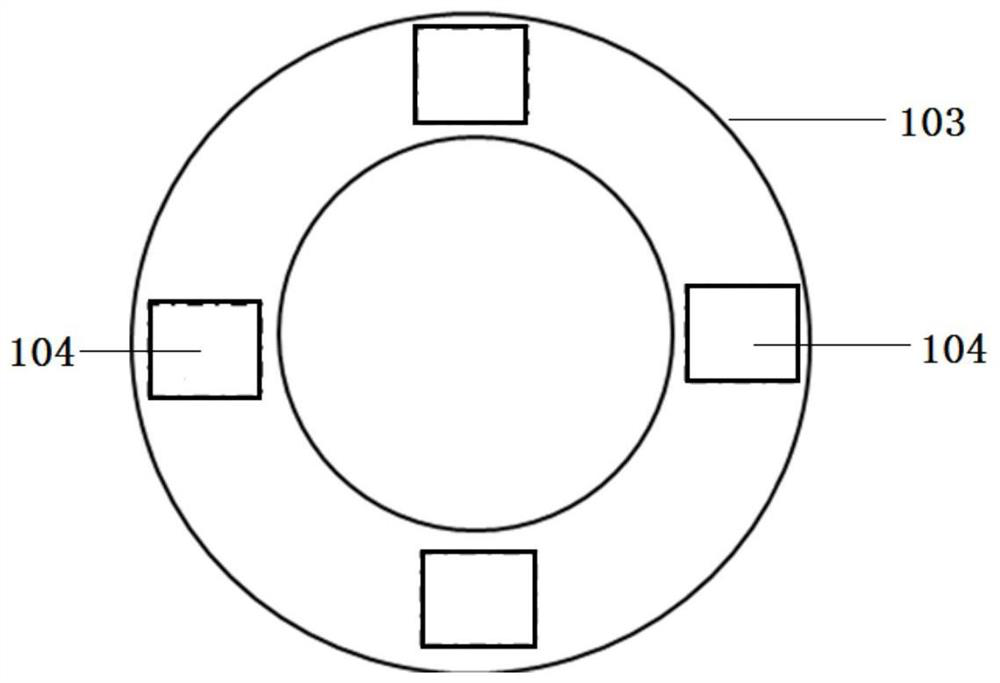

[0060] like figure 1 As shown, the coating reaction generating device 1 includes a casing 101, an ultraviolet light source 102 and a supporting member; the supporting member includes a reactor base 105, a tray support 104 and an annular tray 103; the upper end of the casing is open, and the lower end is fixed to the supporting member; The ultraviolet light source is sealed and sheathed with a glass lampshade, and then installed on the reactor base 105 and connected to the power source; on the reactor base 105, a plurality of tray supports are also fixed in the circumferential direction of the ultraviolet light source, and a circular ring is placed on the tray support. Tray 103; eg figure 2 As shown, it is a top view of the annular tray and the tray support in the coating reaction generating device, wherein the boxes are the positions of the four column-shaped tray support;

[0061] The outer shell 101 is a glass shell without a cover; the ultraviolet light source 102 is used...

Embodiment 2

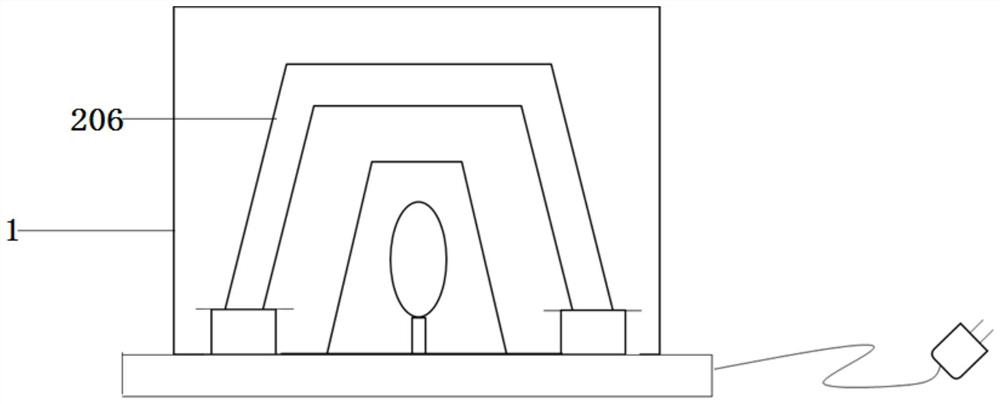

[0063] like Figure 4 As shown in the figure, the multi-stage serial filter system is surrounded by a casing, and the porous ceramic pot filter unit and the porous ceramic plate filter unit are arranged at intervals along the water flow direction in the casing; the top of the casing is provided with a light source 201 and a water inlet 202, and the bottom is provided with a water outlet 213; The light source 201 is a full-spectrum light bulb, which provides a light source for the coating on the inner surface of the 1st porous pottery pot, which helps to exert its photocatalytic performance; When the pollutants enter the tank, it is convenient for external light to enter the tank through the lid; the water outlet 213 is provided with a water outlet valve;

[0064] The battery area 203, as a part of the cover, is equipped with a battery, and is connected with the first vibrating plate, the second vibrating plate, and the full-spectrum bulb through the internal circuit in the cov...

Embodiment 3

[0070] Figure 4 The design capacity of the first porous clay pot is 6-8L. The pentavalent arsenic solution (1-100 mg / L) was added to the first porous earthenware pot. The concentration of pentavalent arsenic in the water is detected, and then the removal rate of pentavalent arsenic by the device is 85-99% through calculation. Calculated as follows:

[0071]

[0072] When the incoming water contains 10 3 ~10 6 When the concentration of Escherichia coli is cfu / mL, the concentration of Escherichia coli in the effluent is less than 1 cfu / mL, and it is calculated that the removal rate of Escherichia coli by this device is greater than 99%.

[0073] In addition, various pollutants were added to deionized water to prepare water to be treated containing various pollutants, including 10-50 cfu / mL Escherichia coli, 1.5 mg / L 1,2-dichlorobenzene, 0.8 mg / L of xylene, 1.2 mg / L of toluene, 0.1 mg / L of arsenic, and 1.5 mg / L of fluoride. Press the switch button 204 to turn on the UV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com