A kind of spirulina oligosaccharide and its application in the preparation of functional preparations for regulating intestinal health

A technology of spirulina and spirulina powder, which is applied in the preparation of preparations for regulating intestinal health functions, in the field of spirulina oligosaccharides, can solve problems such as environmental pollution, achieve good application prospects, good regulation of intestinal flora structure, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

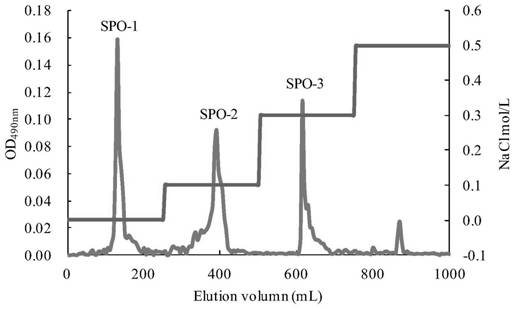

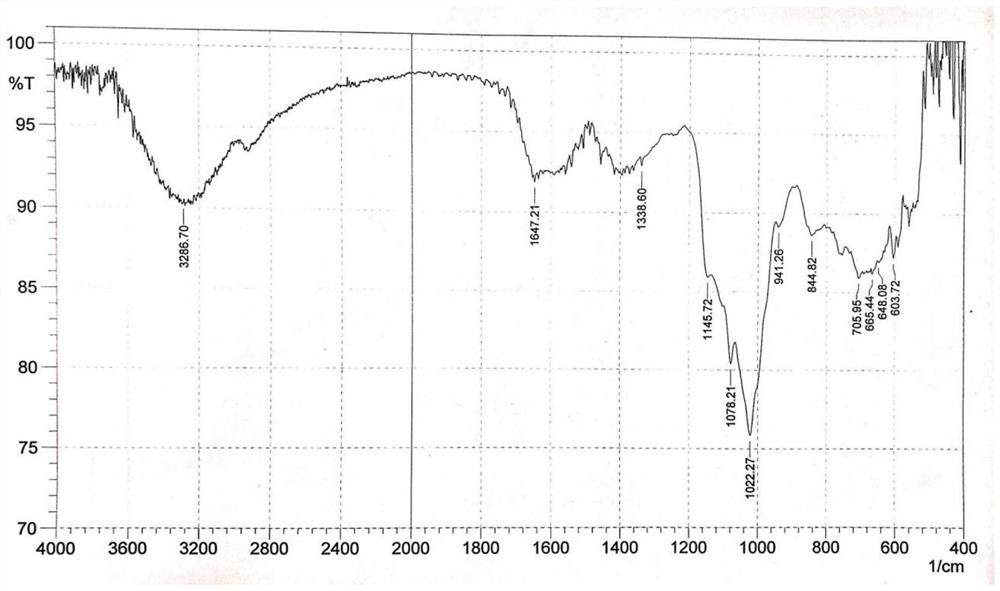

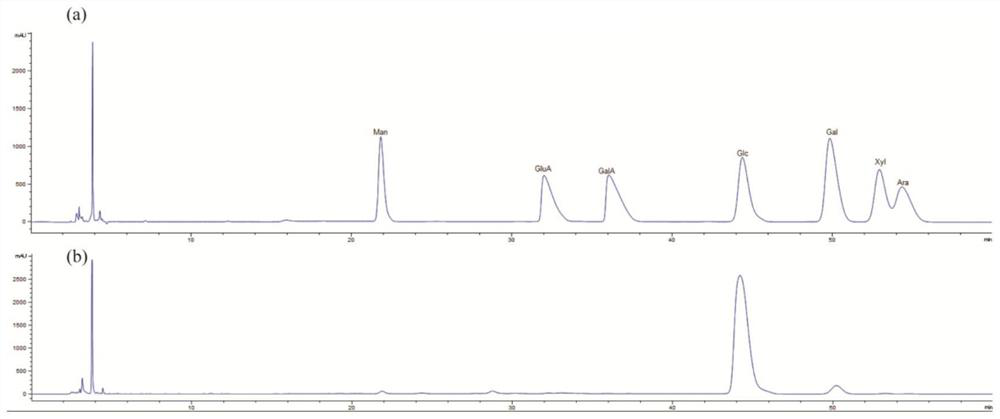

[0029] Preparation of spirulina oligosaccharides: Weigh a certain amount of spirulina powder, add 30 times the volume of distilled water, mix well, put it in a -20°C refrigerator to freeze, thaw at room temperature, and after 3 cycles, use ultrasonic extraction (ultrasonic conditions: power 50 %, time 30min, temperature 80°C), and then stirred at 80°C for 2h. Centrifuge at 10,000r / min for 30min to remove the precipitate. After the supernatant is concentrated by rotary evaporation, add 4 times the volume of absolute ethanol, refrigerate at 4°C overnight, centrifuge to collect the precipitate, add 2 times the volume of distilled water to redissolve, and add 1% papain , after enzymatic hydrolysis at 50°C for 2 hours, after deproteinization by Sevag method, add 1.5% (w / v) activated carbon to decolorize at 40°C for 1 hour, remove the activated carbon by suction filtration, adjust the pH to 8.0, add 500 U / g of marine microbial glycosidase, Hydrolyze at 40°C for 8 hours, inactivate t...

Embodiment 2

[0031] Preparation of spirulina oligosaccharides: Weigh a certain amount of spirulina powder, add 40 times the volume of distilled water, mix well, freeze in a -20°C refrigerator, thaw at room temperature, and cycle 3 times before extracting with ultrasonic waves (ultrasonic conditions: power 50 %, time 30min, temperature 80°C), and stirred at 60°C for 5h. Centrifuge at 10,000r / min for 30min to remove the precipitate. After the supernatant is concentrated by rotary evaporation, add 4 times the volume of absolute ethanol, refrigerate at 4°C overnight, centrifuge to collect the precipitate, add 2 times the volume of distilled water to redissolve, and add 1% papain , after enzymatic hydrolysis at 50°C for 2 hours, after deproteinization by Sevag method, add 1.5% (w / v) activated carbon to decolorize at 40°C for 1 hour, remove the activated carbon by suction filtration, adjust pH to 8.0, add marine microbial glycosidase 2000U / g, Hydrolyze at 50°C for 5 hours, inactivate the enzyme ...

Embodiment 3

[0033] Preparation of spirulina oligosaccharides: Weigh a certain amount of spirulina powder, add 20 times the volume of distilled water, mix well, freeze in a -20°C refrigerator, thaw at room temperature, and cycle 3 times, then use ultrasonic extraction (ultrasonic conditions: power 50 %, time 30min, temperature 80°C), and then stirred at 90°C for 2h. Centrifuge at 10,000r / min for 30min to remove the precipitate. After the supernatant is concentrated by rotary evaporation, add 3 times the volume of absolute ethanol, refrigerate overnight at 4°C, centrifuge to collect the precipitate, add 2 times the volume of distilled water to redissolve, and add 1% papain , after enzymatic hydrolysis at 50°C for 2 hours, after deproteinization by Sevag method, add 1.5% (w / v) activated carbon to decolorize at 40°C for 1 hour, remove the activated carbon by suction filtration, adjust pH to 8.0, add marine microbial glycosidase 1000U / g, Hydrolyze at 30°C for 8 hours, inactivate the enzyme in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com