Anti-adhesion composite multi-layer amnion material

A technology for preventing adhesion and amniotic membrane, applied in the field of composite multi-layer amniotic membrane materials, can solve the problems of low mechanical strength, easy slippage, easy tearing, etc., to achieve the effect of improving mechanical strength and solving easy tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation of freeze-dried amniotic membrane: put the fresh amniotic membrane in the working room of the freeze dryer, pre-freeze at low temperature for several hours, turn on the condensation chamber to refrigerate, make the temperature of the cold trap reach -10℃~-56℃, turn on the vacuum pump, vacuum freeze-dry, water content is reduced to below 20%. Freeze-dried amnion was sterilized by cobalt 60 irradiation.

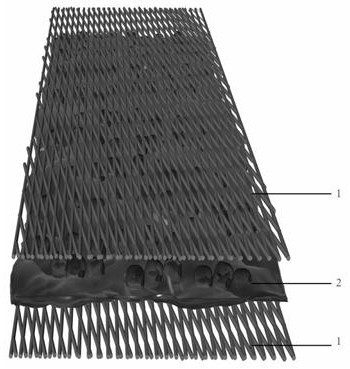

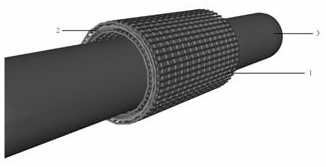

[0020] Preparation of electrospun amniotic matrix nanofibrous membrane: Prepare polycaprolactone (PCL) spinning liquid, stir and mix overnight with a magnetic bar. Set various parameters such as ambient temperature and humidity, and connect the electrospinning device. Put the electrospinning solution into the syringe, adjust the flow rate of the solution, high voltage, and adjust the receiving distance to receive the PCL fiber membrane on the two surfaces of the lyophilized amniotic membrane. The prepared nanofiber membrane was dried overnight in a vacu...

Embodiment

[0021] Example: after blunt separation between the amnion and chorion to obtain smooth, translucent fresh amnion, soak it in a balanced salt solution containing 50ug / ml penicillin and 50ug / ml streptomycin for 20 minutes, and place it in DMEM medium Store in the refrigerator at 4°C until use. Put the fresh amniotic membrane in the working room of the freeze dryer, pre-freeze at 0°C to -50°C for 1 to 10 hours, turn on the condensation chamber to cool down, make the temperature of the cold trap reach -10°C to -56°C, turn on the vacuum pump, and vacuum freeze dry. The moisture content ranges from 1% to 20%. Freeze-dried amnion was sterilized by cobalt 60 irradiation. Prepare polycaprolactone (PCL) spinning solution, stir and mix overnight with a magnetic bar. Set the ambient temperature to 25°C and the humidity to 60%, and connect the electrospinning device. Put the electrospinning solution into a 2ml syringe with a needle with a diameter of 0.7mm, adjust the flow rate of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com