Reinforced modified PET polyester blend and polyethylene glycol terephthalate blend plastic

A technology of polyethylene terephthalate and blends, applied in the field of polymer materials, can solve problems such as increased production costs, increased personnel burns, unfavorable environmental protection, etc., and achieves increased crystallization temperature, accelerated crystallization rate, mechanical The effect of not degrading performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

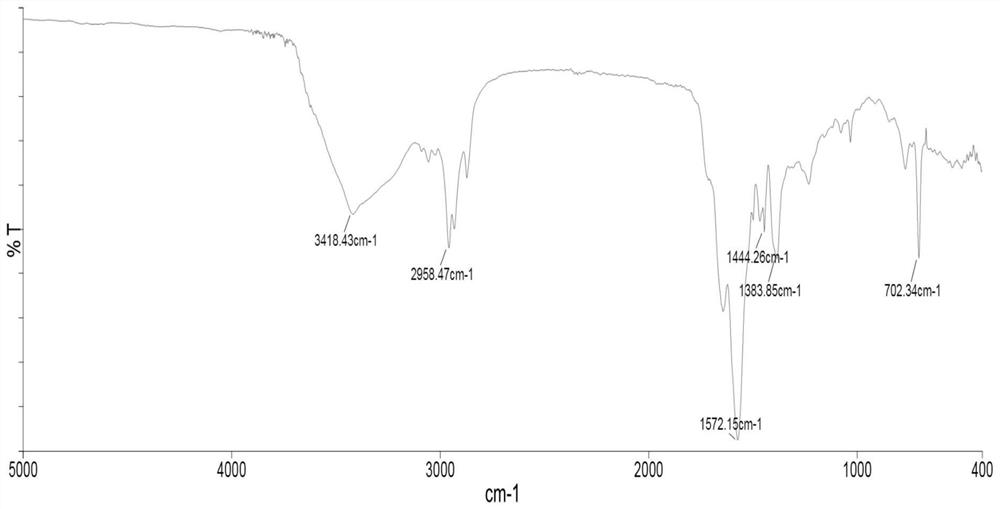

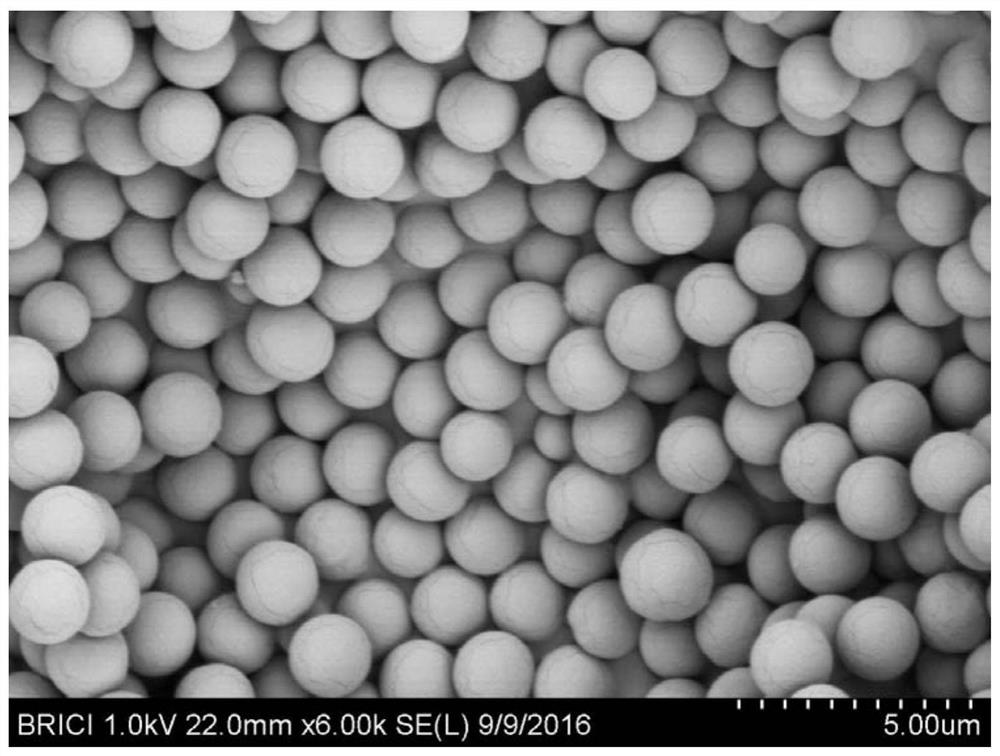

[0075] (1) Dissolve 100g of maleic anhydride, 118g of α-methylstyrene, 26g of divinylbenzene, and 2g of azobisisobutyronitrile in 1000mL of isoamyl acetate, and react at 70°C for 5 hours under a nitrogen atmosphere . The reacted system was centrifuged by a centrifuge at 5000 rad / min for 30 minutes to obtain cross-linked α-methylstyrene / maleic anhydride polymer microspheres, which were washed and purified with n-hexane and dried in vacuum. At the same time, the supernatant after centrifugation is analyzed by LC-MC (liquid chromatography-mass spectrometry on-line), and the remaining monomer amount is measured, and the remaining monomer amount is subtracted from the input monomer amount (or cross-linking amount). Quantity (or crosslinking dosage) obtains the monomer quantity (or crosslinking dosage) that actually participates in the reaction, thereby obtains the molar ratio between structural unit A, structural unit B and crosslinking structure, as shown in Table 1 below.

[007...

preparation Embodiment 2

[0078] (1) Dissolve 100g of maleic anhydride, 118g of α-methylstyrene, 26g of divinylbenzene, and 2g of azobisisobutyronitrile in 1000mL of isoamyl acetate, and react at 70°C for 5 hours under a nitrogen atmosphere . After the reaction, the system was centrifuged at 5000 rad / min for 30 minutes to obtain cross-linked α-methylstyrene / maleic anhydride polymer microspheres, which were washed and purified with methanol and dried in vacuum; the structural characteristics are shown in Table 1 Show.

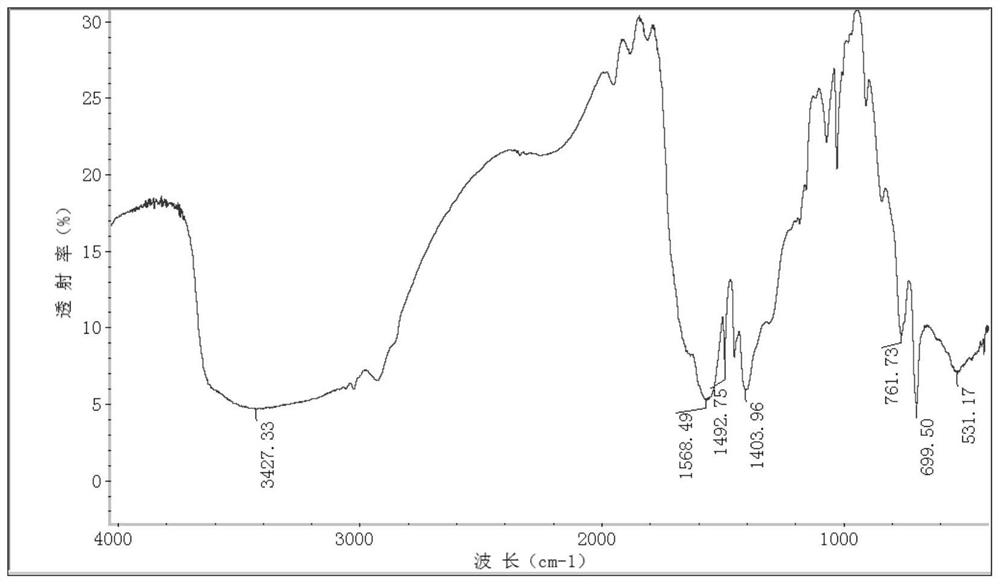

[0079] (2) Join 50g of cross-linked α-methylstyrene / maleic anhydride polymer microspheres into 400mL dispersant n-heptane, then add 6.2g potassium hydroxide (relative to every mole of maleic anhydride, alkali 0.55 mol) and 83.8 g of aniline (4.5 mol per mol of maleic anhydride) were reacted at 80° C. for 2.5 hours. The reacted system was centrifuged under the condition of 5000rad / min for 30 minutes by a centrifuge, 300mL of ethanol was added to the obtained solid for stirring and washi...

preparation Embodiment 3

[0081] (1) 130 g of maleic anhydride, 104 g of styrene, 26 g of divinylbenzene, and 2.5 g of azobisisobutyronitrile were dissolved in 1000 mL of isoamyl acetate, and reacted at 60° C. for 10 hours under a nitrogen atmosphere. After the reaction, the system was centrifuged under the condition of 5000rad / min for 30 minutes to obtain cross-linked α-methylstyrene / maleic anhydride polymer microspheres, which were washed with methanol and dried in vacuum; the structural characteristics are shown in Table 1 below .

[0082] (2) Join 50g of cross-linked α-methylstyrene / maleic anhydride polymer microspheres in 350mL dispersant n-hexane, then add 3.6g sodium hydroxide (relative to the maleic anhydride per mole, the consumption of alkali 0.45 mol) and 22.0 g of 2-hydroxyethylamine (the amount of amine used is 1.7 mol per mol of maleic anhydride), and reacted at 30° C. for 7 hours. After the reaction, the system was centrifuged under the condition of 5000rad / min for 30 minutes, and 400mL...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com