Preparation method of zinc ion battery positive electrode material and electrode material prepared by preparation method

A technology for zinc ion batteries and positive electrode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of high price and complex process, and achieves low cost, simple preparation process, good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

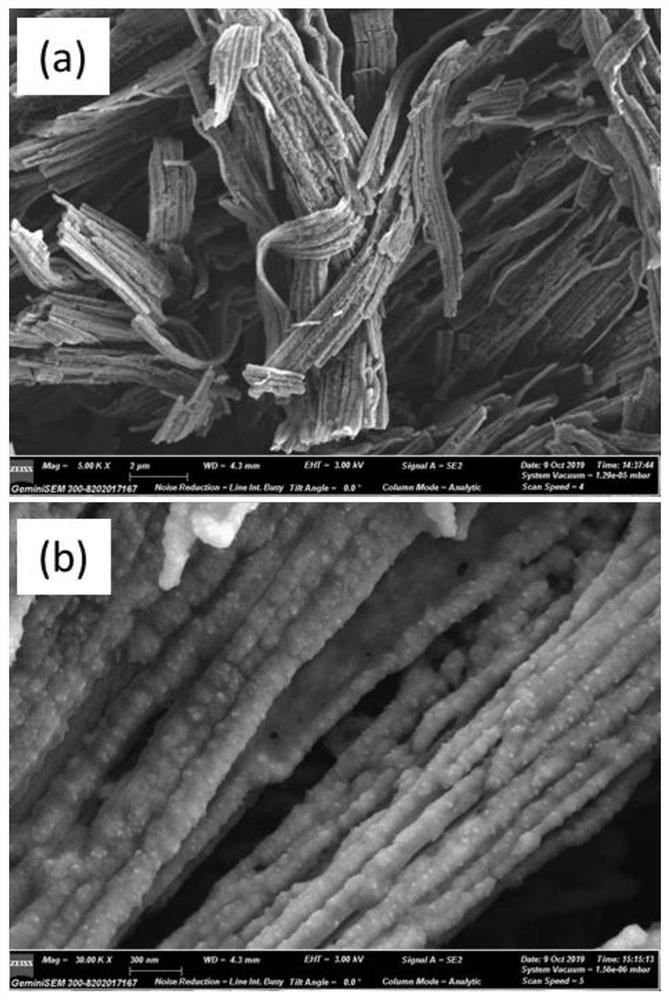

[0036] First, add 2mmol sodium dodecylbenzenesulfonate and 10mmol aniline hydrochloride to 40mL deionized water in sequence, and stir to completely dissolve the sodium dodecylbenzenesulfonate and aniline hydrochloride. Then, the mixed solution system was placed in an ice-water bath, cooled to 0-4° C., 10 mmol of ammonium persulfate was added, stirred evenly, and left to react at 4° C. for 12 hours to form a stable polyaniline hydrogel. Finally, the above-mentioned polyaniline hydrogel was washed 5 times with a large amount of deionized water, and freeze-dried to obtain a product polyaniline material that can be used as a positive electrode material for a zinc-ion battery.

Embodiment 2

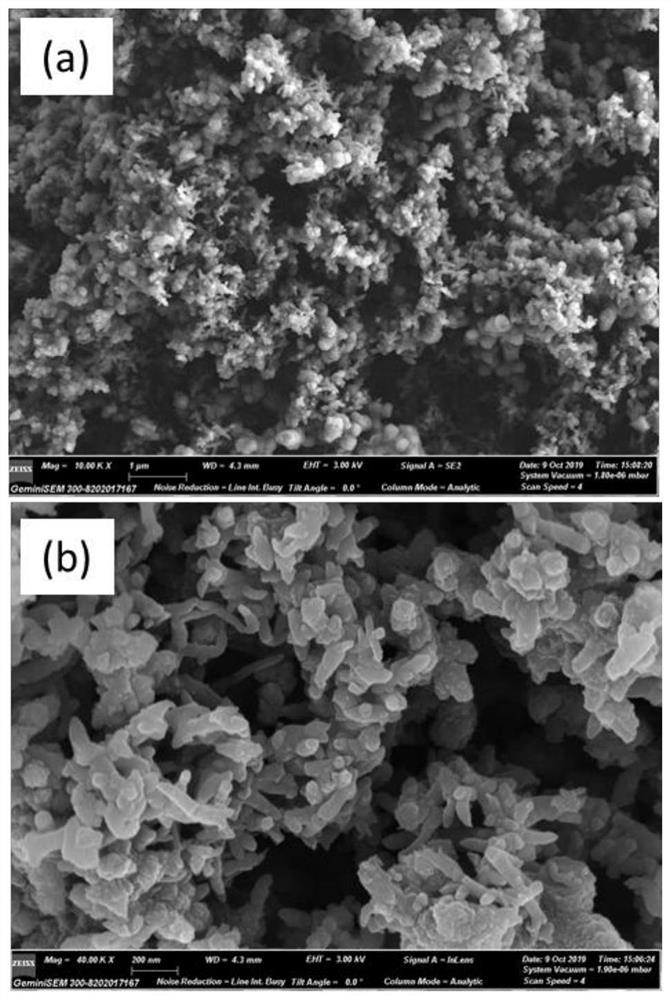

[0038] First, add 2mmol sodium dodecylbenzenesulfonate and 12mmol aniline hydrochloride to 40mL deionized water in sequence, and stir to completely dissolve the sodium dodecylbenzenesulfonate and aniline hydrochloride. Then, the mixed solution system was placed in an ice-water bath, cooled to 0-4° C., 7 mmol potassium permanganate was added, stirred evenly, and left to react at 4° C. for 12 hours to form a stable polyaniline hydrogel. Finally, the above-mentioned polyaniline hydrogel was washed 5 times with a large amount of deionized water, and freeze-dried to obtain the product polyaniline material.

Embodiment 3

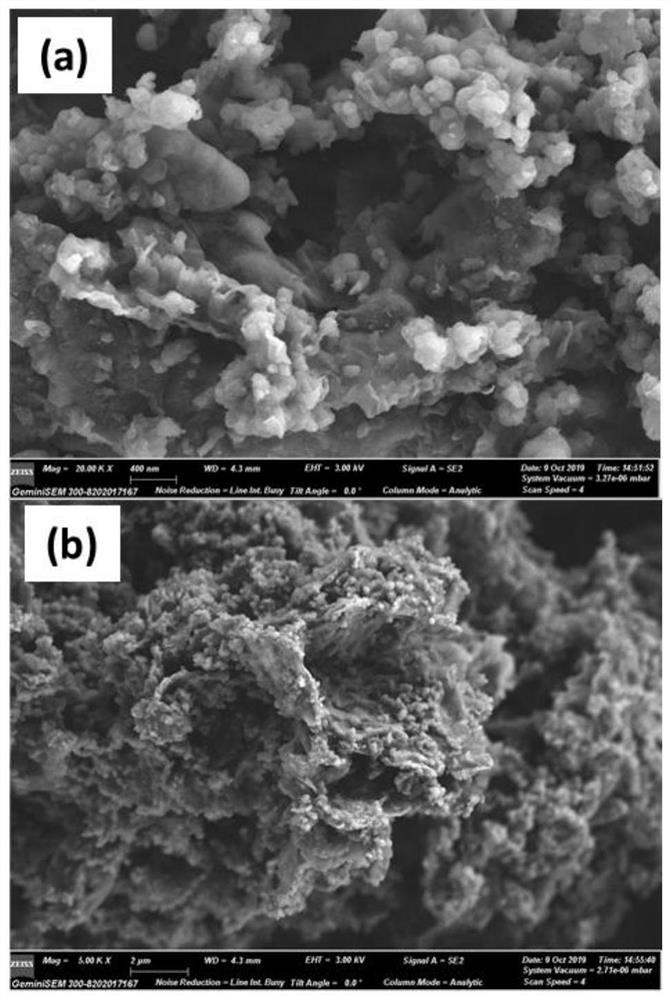

[0040] First, add 2mmol sodium dodecylbenzenesulfonate and 12mmol aniline hydrochloride to 40mL deionized water in sequence, and stir to completely dissolve the sodium dodecylbenzenesulfonate and aniline hydrochloride. Then, the mixed solution system was placed in an ice-water bath, cooled to 0-4° C., 12 mmol of ammonium persulfate was added, stirred evenly, and left to react at 4° C. for 24 hours to form a stable polyaniline hydrogel. Finally, the above-mentioned polyaniline hydrogel was washed 5 times with a large amount of deionized water, and freeze-dried to obtain the product polyaniline material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com