Novel nano-catalyst with visible light response as well as preparation method and application thereof

A nano-catalyst and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as low utilization rate of solar energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In a second aspect, the application provides a method for preparing a novel nanocatalyst responding to visible light, which specifically includes the following steps:

[0033] (1) Dissolve citric acid and urea with a mass ratio of (2-3):1 in deionized water, transfer to an autoclave at 160°C-180°C for 6h-10h, cool to room temperature, and react The product is centrifuged to take the supernatant, and further vacuum freeze-dried to prepare CDs; wherein, the heating rate during the calcination process is 3° C. / min to 5° C. / min.

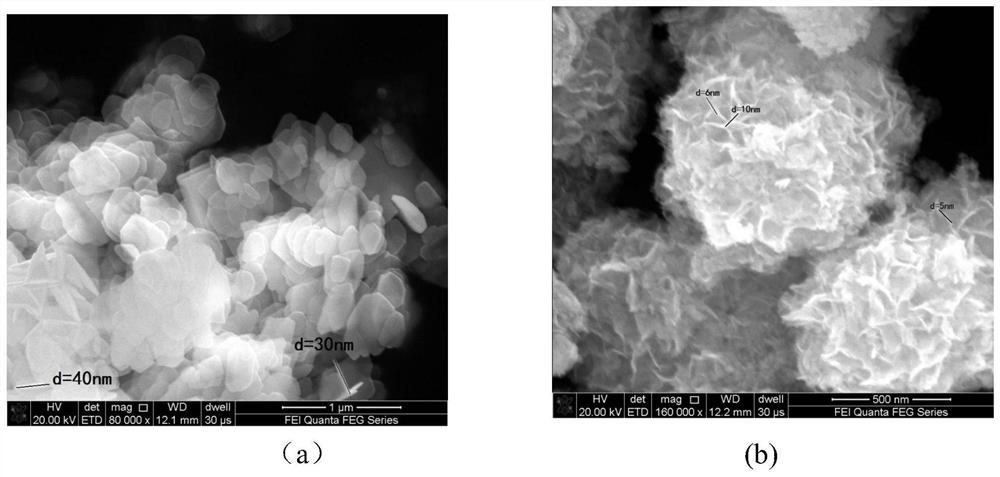

[0034] (2) KCl and Bi(NO 3 ) 3 ·5H 2 O was dissolved in glycerol or ethylene glycol, respectively, and then the KCl solution was slowly added to the Bi(NO 3 ) 3 ·5H 2 In the O solution, stir constantly to ensure thorough mixing, then transfer the mixture to an autoclave, and conduct a hydrothermal reaction at 160°C to 180°C for 15h to 18h; after cooling to room temperature, the reaction product is subjected to centrifugal washing treatment, a...

Embodiment 1

[0047] Step 1: Accurately weigh 3.0 g of citric acid and 1.0 g of urea and dissolve them in 20 ml of deionized water, then transfer the above solution to an autoclave, and react at 180°C for 8 hours. After cooling to room temperature, the mixture was transferred to a centrifuge tube, centrifuged at high speed for 30 min, and the supernatant was freeze-dried to obtain CDs powder;

[0048] Step 2, accurately weigh 2mmol of Bi(NO 3 ) 3 ·5H 2 O and 2mmol KCl were dissolved in 30ml of glycerol, and ultrasonically stirred until the reactants were completely dissolved, then the two were mixed and stirred to obtain a white suspension. Then the white suspension was transferred to a 100 mL autoclave and reacted at 160° C. for 16 hours. After cooling to room temperature, it was centrifuged and washed several times with absolute ethanol and deionized water, and the obtained precipitate was dried at 60 °C to obtain BiO 1-x Cl.

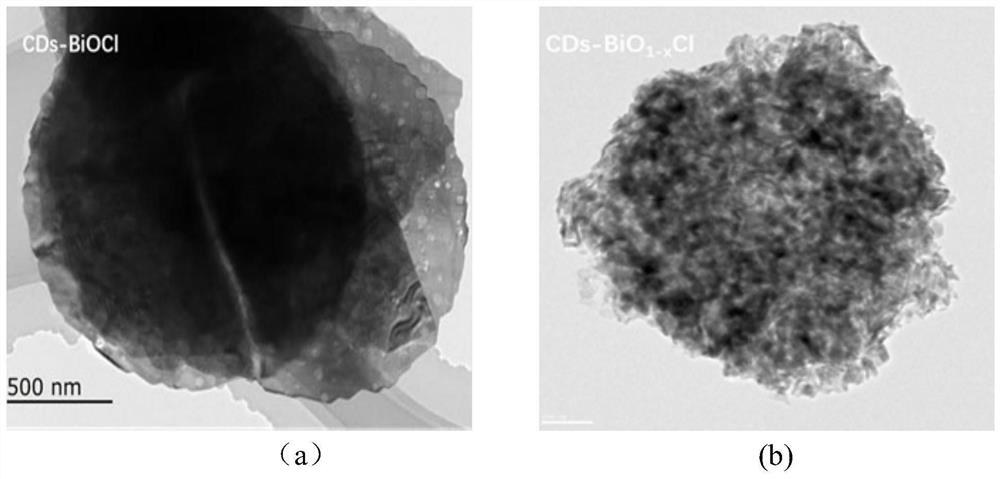

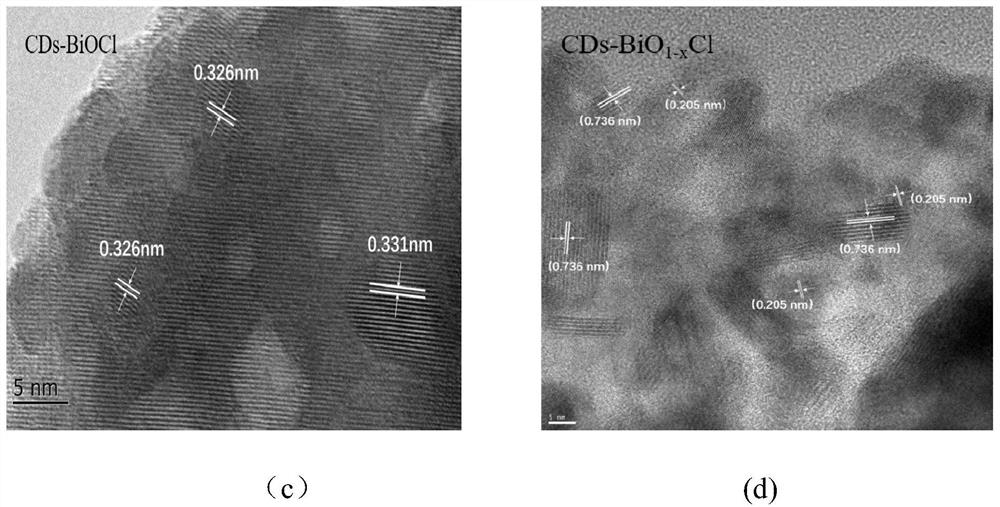

[0049] Step 3, accurately weigh 25mg of CDs powder obtai...

Embodiment 2

[0051] Step 1: Accurately weigh 3.0 g of citric acid and 1.0 g of urea and dissolve them in 20 ml of deionized water, then transfer the above solution to an autoclave, and react at 180°C for 8 hours. After cooling to room temperature, the mixture was transferred to a centrifuge tube, centrifuged at high speed for 30 min, and the supernatant was freeze-dried to obtain CDs powder;

[0052] Step 2, accurately weigh 2mmol of Bi(NO 3 ) 3 ·5H 2 O and 2mmol KCl were dissolved in 30ml of glycerol, and ultrasonically stirred until the reactants were completely dissolved, then the two were mixed and stirred to obtain a white suspension. Then the white suspension was transferred to a 100 mL autoclave and reacted at 160° C. for 16 hours. After cooling to room temperature, it was centrifuged and washed several times with absolute ethanol and deionized water, and the obtained precipitate was dried at 60 °C to obtain BiO 1-x Cl.

[0053] Step 3, accurately weigh 5mg of CDs powder obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com