Silicon-carbon composite material and preparation method thereof, negative electrode and battery

A silicon-carbon composite material and carbon material technology, applied in negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of affecting battery cycle performance, easy powdering and peeling of silicon negative electrode materials, etc., to improve cycle performance and buffer volume. The effect of swelling and increasing cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

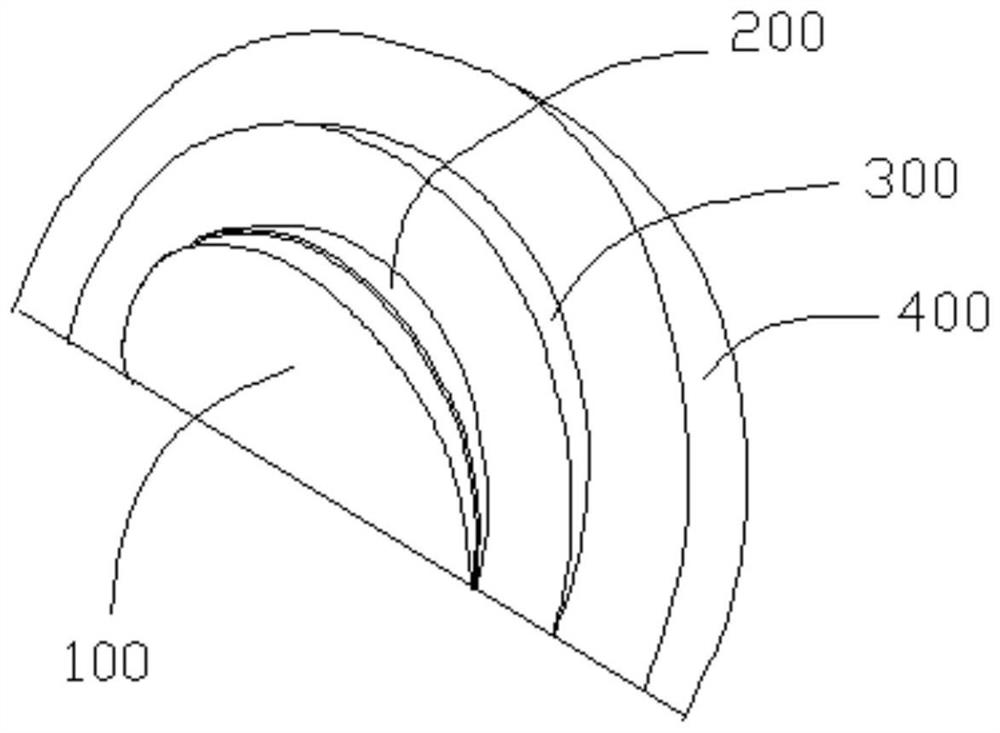

[0062] Another aspect of the present invention provides a method for preparing a silicon-carbon composite material. The preparation method includes: forming the metal layer on the surface of the silicon nanoparticle; forming the metal layer on the surface of the metal layer. carbon material layer to obtain the silicon-carbon composite material.

[0063] In some embodiments of the present invention, the preparation method includes: mixing the silicon nanoparticles, the metal salt solution, and the polymer monomer as a carbon source material, and then performing a polymerization reaction under the action of an oxidizing agent, and the intermediate is obtained after the reaction. product; the intermediate product is pyrolyzed to obtain the silicon-carbon composite material.

[0064] It should be noted that during the mixing process, metal ions tend to gather on the surface of silicon nanoparticles compared to the polymer monomer as a carbon source material, and then the polymer m...

Embodiment 1

[0076] The preparation method of silicon carbon composite material is as follows:

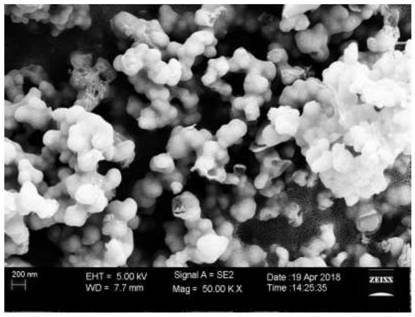

[0077] (1) Disperse 1g of nano-silicon powder (particle size is about 100nm, roughly in the range of 80nm-120nm) in 0.1g / L copper nitrate solution, add 1g of pyrrole, stir for half an hour, so that the nano-silicon powder is fully dispersed in nitric acid in the copper solution. 40 mL of hydrochloric acid was added to initiate pyrrole polymerization to obtain a suspension. The suspension was vacuum filtered and dried in an oven for 12 hours to obtain a precursor, labeled as Si@Cu(NO 3 ) 2 @PPY.

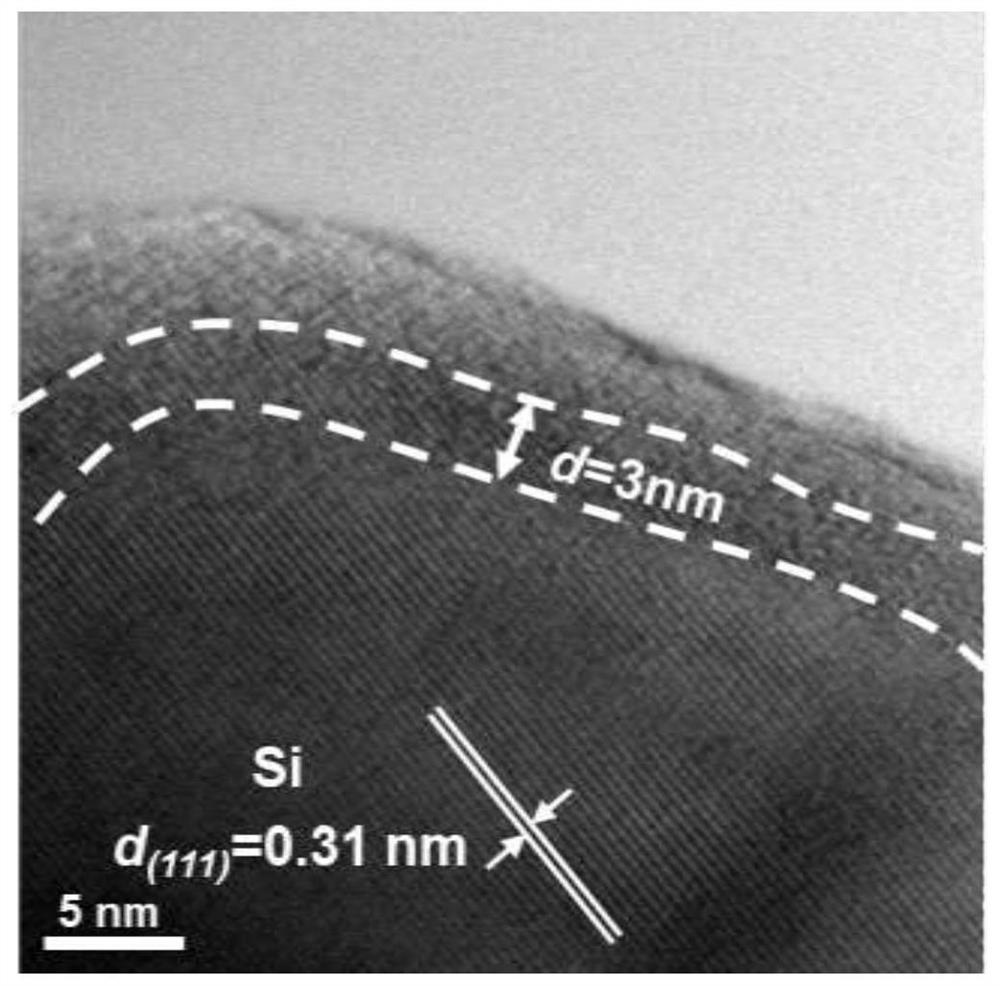

[0078] (2) The precursor Si@Cu(NO 3 ) 2 @PPY is placed in a porcelain boat and placed in a tube furnace, filled with argon protective gas, heated to 900°C, kept warm for 3 hours, cooled to room temperature, washed with distilled water and ethanol three times, filtered with suction, and dried in vacuum for 12 hours to obtain Silicon-carbon composites (marked as Si@Cu@C).

[0079] figure 2 It is...

Embodiment 2

[0083] The preparation method of silicon carbon composite material is as follows:

[0084] (1) Disperse 1g of nano-silicon powder (particle size is about 500nm, roughly in the range of 450-550nm) in 0.2g / L copper nitrate solution, add 1g of pyrrole, stir for half an hour, so that the silicon powder is fully dispersed in copper nitrate solution. 1 g of ammonium persulfate was added to initiate polymerization to obtain a suspension. The suspension was vacuum filtered and dried in an oven for 12 hours to obtain a precursor.

[0085] (2) Put the precursor in a porcelain boat and put it into a tube furnace, pass through argon protective gas, heat up to 800°C, keep warm for 3 hours, cool to room temperature, wash with distilled water and ethanol three times respectively, suction filter, vacuum Dry for 12 hours to obtain a silicon-silicon-carbon composite material.

[0086] In the silicon-carbon composite material of Example 2, the content of silicon nanoparticles is 60%, the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com