Co-extrusion type base-coat-free matt film with antibacterial function and preparation method of co-extrusion type base-coat-free matt film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

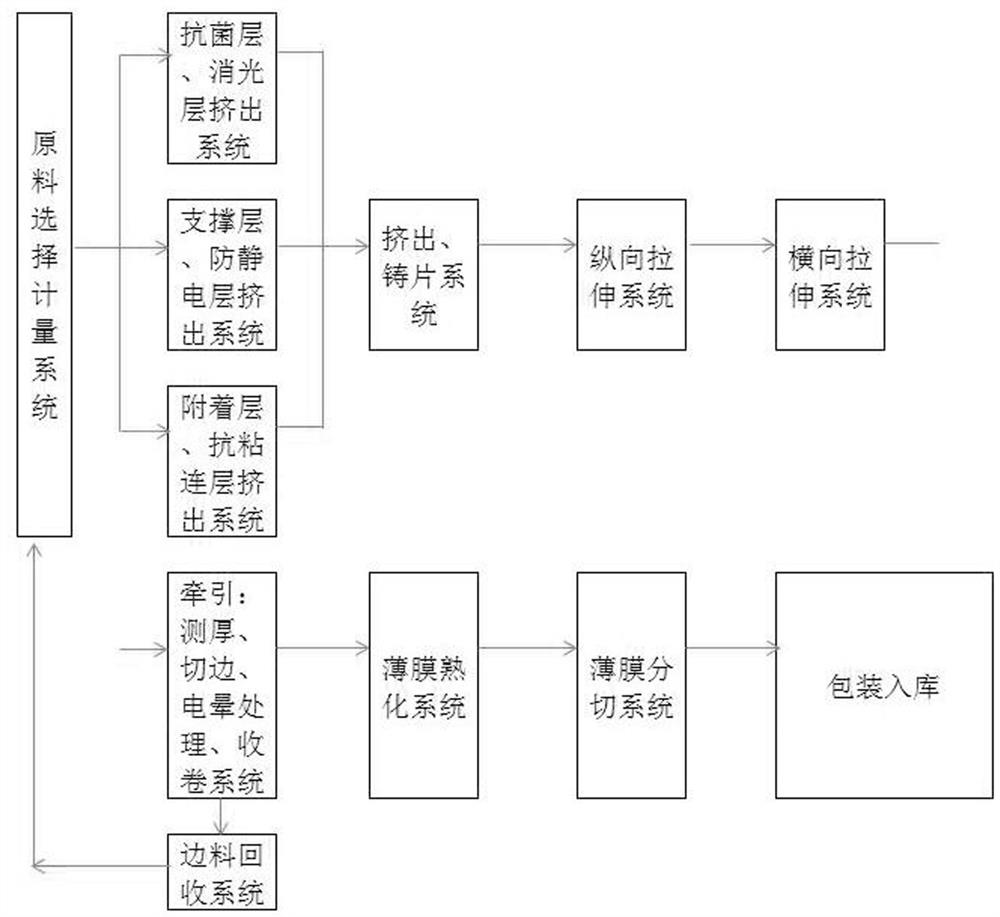

Method used

Image

Examples

Embodiment 1

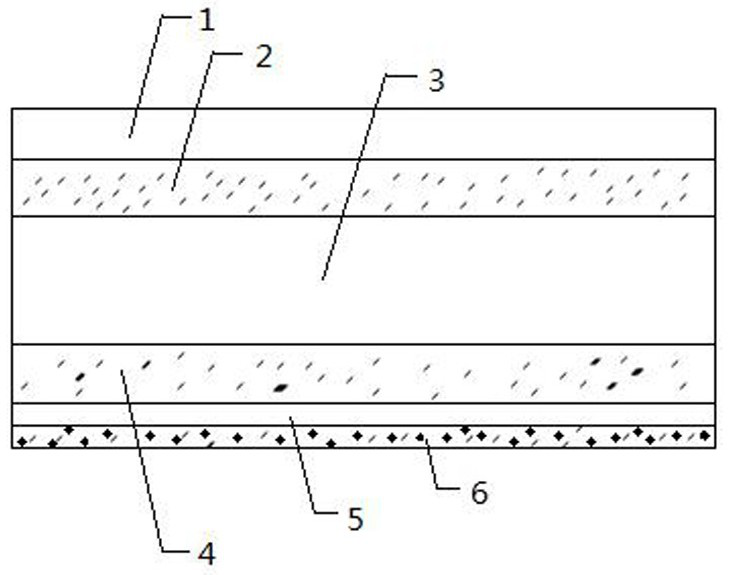

[0034]A co-extruded antibacterial function primerless matting film, including a film body, the film body sequentially includes an antibacterial agent layer 1, a matting layer 2, an antistatic layer 3, a support layer 4, and an adhesive layer 5 from top to bottom And the anti-adhesion agent layer 6, the antibacterial components of the antibacterial agent layer (1) include graphene and its derivatives, sodium hypochlorite, nano-silver, cuprous oxide, zinc oxide, polyhexamethylene biguanide hydrochloride, polyhexamethylene One or more of methylene guanidine hydrochloride, polyhexamethylene guanidine phosphate, organosilicon quaternary ammonium salt, peony flower root bark extract, the antibacterial composition of antibacterial agent layer 1 described in this embodiment It is the root bark extract of peony flower. The root bark extract of peony flower in this example uses the dried root bark of Ranunculaceae plant peony as raw material, and is extracted by ethanol extraction method...

Embodiment 2

[0040] A co-extruded antibacterial function primerless matting film, including a film body, the film body sequentially includes an antibacterial agent layer 1, a matting layer 2, an antistatic layer 3, a support layer 4, and an adhesive layer 5 from top to bottom And anti-blocking agent layer 6, the antibacterial composition of described antibacterial agent layer 1 comprises graphene and derivative thereof, sodium hypochlorite, nano-silver, cuprous oxide, zinc oxide, polyhexamethylene biguanide hydrochloride, polyhexamethylene One or more of guanidine hydrochloride, polyhexamethylene guanidine phosphate, organosilicon quaternary ammonium salt, peony flower root bark extract, the antibacterial component of the antibacterial agent layer 1 described in the present embodiment is peony Flower root bark extract, the root bark extract of peony flower in the present embodiment uses the dried root bark of Ranunculaceae plant peony as raw material, and extracts by ethanol extraction meth...

Embodiment 3

[0046] A co-extruded antibacterial function primerless matting film, including a film body, the film body sequentially includes an antibacterial agent layer 1, a matting layer 2, an antistatic layer 3, a support layer 4, and an adhesive layer 5 from top to bottom And anti-blocking agent layer 6, the antibacterial composition of described antibacterial agent layer 1 comprises graphene and derivative thereof, sodium hypochlorite, nano-silver, cuprous oxide, zinc oxide, polyhexamethylene biguanide hydrochloride, polyhexamethylene One or more of guanidine hydrochloride, polyhexamethylene guanidine phosphate, organosilicon quaternary ammonium salt, peony flower root bark extract, the antibacterial component of the antibacterial agent layer 1 described in the present embodiment is peony Flower root bark extract, the root bark extract of peony flower in the present embodiment uses the dried root bark of Ranunculaceae plant peony as raw material, and extracts by ethanol extraction meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com