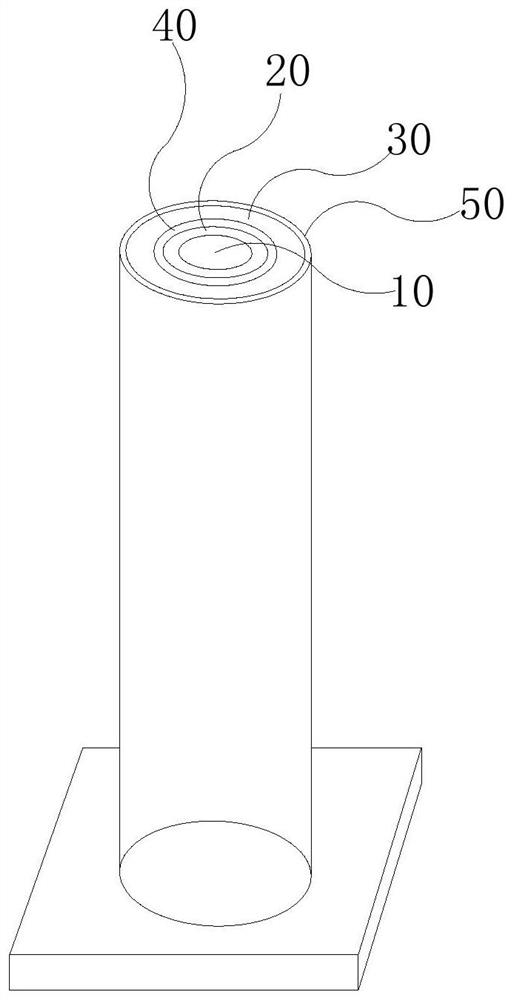

Composite material and preparation method thereof

A composite material and oxide layer technology, which is applied in the manufacture of final products, sustainable manufacturing/processing, electrical components, etc., can solve problems such as poor performance of optoelectronic devices, many surface defects of silicon nanowires, and low luminous efficiency of silicon quantum dots , to achieve the effect of improving the luminous intensity and increasing the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

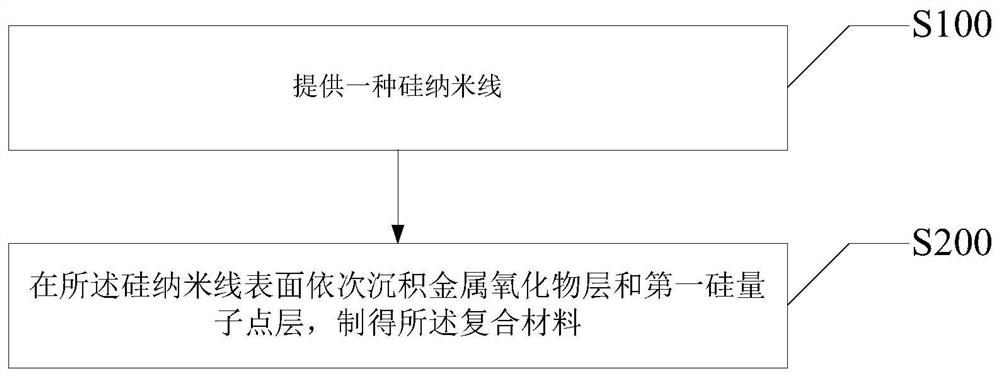

Method used

Image

Examples

Embodiment approach

[0038] Some embodiments of the present invention, the preparation of described composite material also comprises the step:

[0039] Alternating layers are deposited on the surface of the first silicon dioxide layer, and the alternating layers include second silicon quantum dot layers and second silicon dioxide layers alternately in sequence.

[0040] In some embodiments, the step of preparing the alternating layers comprises:

[0041] In the first step, 5-10% SiH is introduced into the reaction chamber 4 Gas and 90-95% Ar gas are used as reaction gases, and the flow rate is controlled at 5-15 standard ml / min by adjusting the mass flow meter; after the gas flow is stable, turn on the RF plasma power supply, the RF power is 50-60W, and the temperature Keep the temperature at 200-260°C for plasma chemical vapor deposition to prepare a silicon film, and deposit for 10-15s;

[0042] In the second step, continue to feed oxygen into the reaction chamber as the reaction gas, and con...

Embodiment 1

[0047] Preparation of silicon nanowires:

[0048] Mix silver nitrate, hydrofluoric acid and deionized silicon according to the mass ratio of 1:2:6 to prepare an etching solution; then place the silicon wafer in the etching solution for 10 minutes, take it out and wash it with concentrated nitric acid Wash with deionized water several times to obtain silicon nanowires.

[0049] The preparation of composite material, specific steps are as follows:

[0050] Using gaseous trimethylaluminum as the precursor, water as the reactant and nitrogen as the carrier gas, set the temperature of the reaction chamber at 160°C, the process pressure at 0.2torr, and the cycle period of 50 to prepare a 4nm-thick aluminum oxide film on the surface of the silicon nanowire . Put the above-mentioned silicon nanowires deposited with alumina into a vacuum chamber, and nitrogen gas is introduced after vacuuming, the total sputtering pressure is at 1Pa, and then a nano-metal layer is deposited on the su...

Embodiment 2

[0054] Preparation of silicon nanowires:

[0055] Mix silver nitrate, hydrofluoric acid and deionized silicon according to the mass ratio of 1:2:6 to prepare an etching solution; then place the silicon wafer in the etching solution for 10 minutes, take it out and wash it with concentrated nitric acid Wash with deionized water several times to obtain silicon nanowires.

[0056] The preparation of composite material, specific steps are as follows:

[0057] Using gaseous trimethylaluminum as the precursor, water as the reactant and nitrogen as the carrier gas, set the temperature of the reaction chamber at 160°C, the process pressure at 0.2torr, and the cycle period of 50 to prepare a 4nm-thick aluminum oxide film on the surface of the silicon nanowire . Put the above-mentioned silicon nanowires deposited with alumina into a vacuum chamber, and nitrogen gas is introduced after vacuuming, the total sputtering pressure is at 1Pa, and then a thin layer of gold is deposited on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com