Lithium ion battery and preparation method thereof

A lithium-ion battery and electrolyte technology, which is applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as affecting electrochemical performance, increasing battery interface impedance, and deteriorating battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

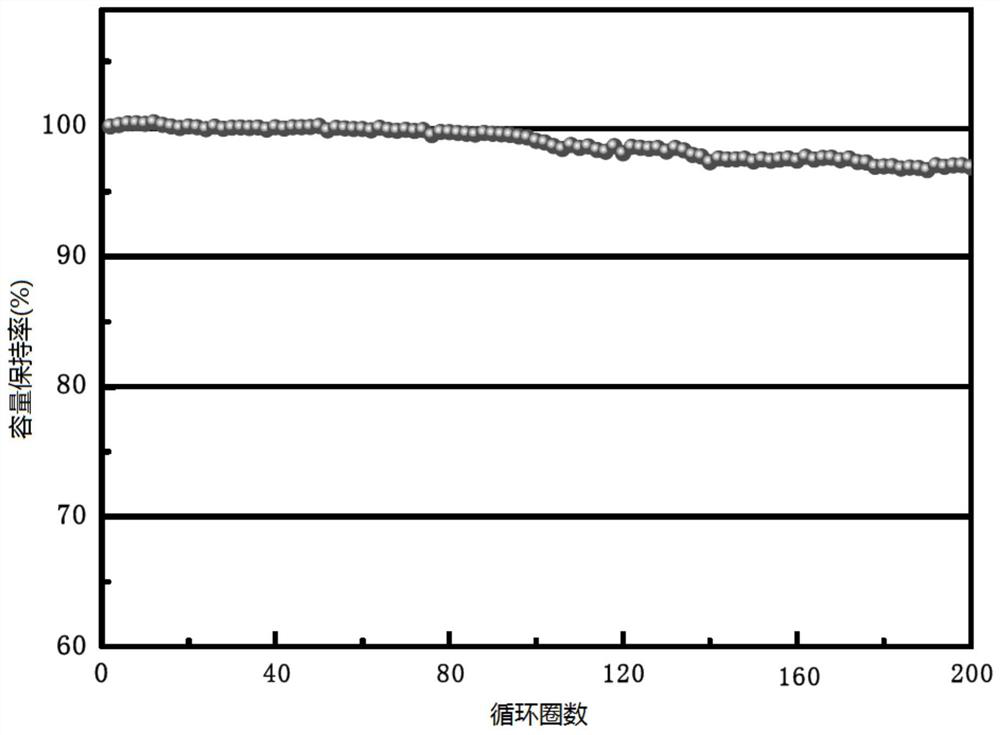

Examples

Embodiment 1

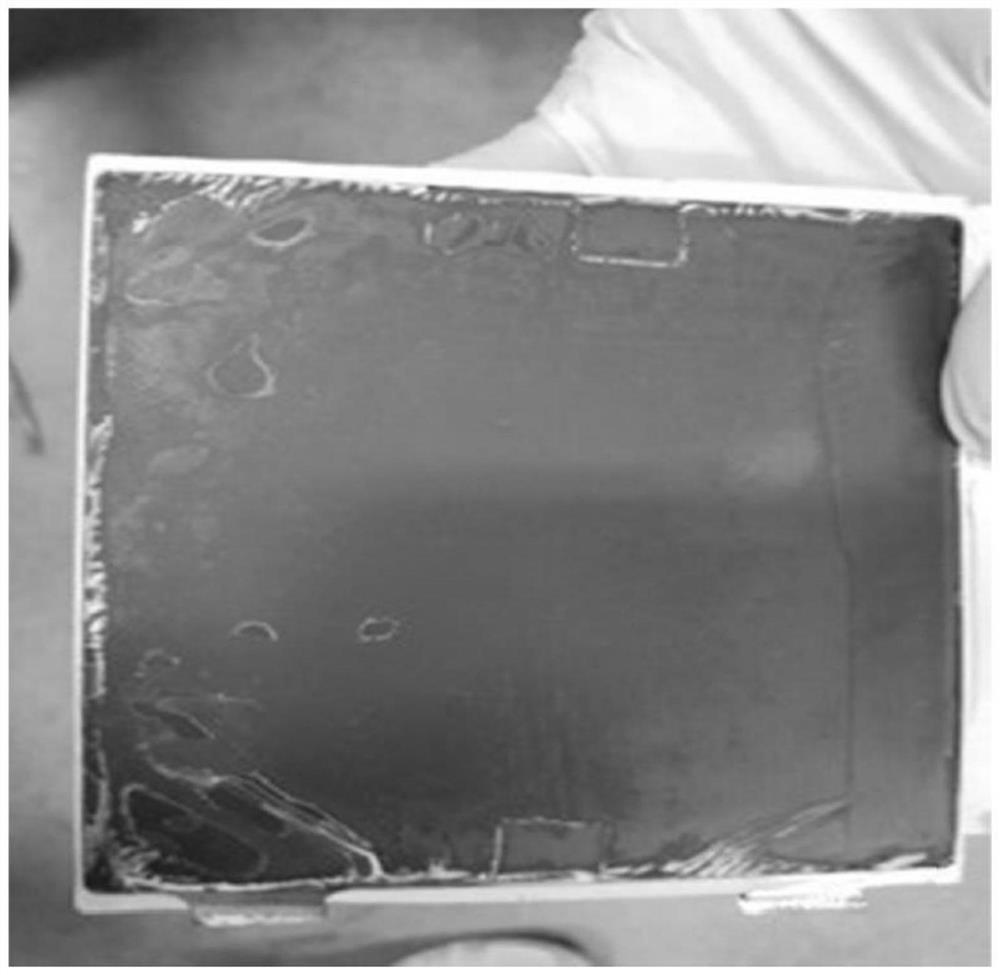

[0029] Positive sheet preparation:

[0030] Based on the total mass of the positive electrode material being 100%, 98.25 wt% of NCM811, 0.75 wt% of conductive agent (sp) and 1.0 wt% of PVDF were weighed. The weighed PVDF was configured into an NMP solution with a solid content of 8.0 wt%. Sequentially add the weighed conductive agent (sp) and ternary material to disperse evenly, add NMP to adjust viscosity, and form positive electrode slurry. The positive electrode slurry is coated on the aluminum foil, and after drying, it is rolled and cut to obtain the positive electrode sheet.

[0031] Negative sheet preparation:

[0032] It is 100% by negative electrode material gross mass, weigh the silicon oxygen (SiO) material of 6wt%, the graphite of 90wt%, the conductive agent (sp) of 0.75wt%, the CNT of 0.25wt%, the binding agent of 3wt% ( PVDF). Add the weighed silicon oxide, graphite and sp into the dispersing equipment and stir evenly, then add SWCNT (conductive carbon black)...

Embodiment 2

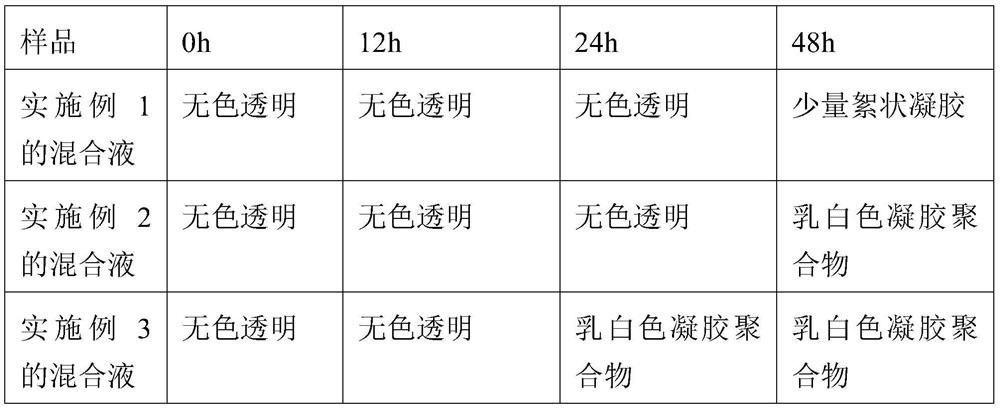

[0040] Except that the preparation of the mixed solution is different from that in Example 1, other preparation processes are the same as in Example 1.

[0041] Mixture preparation:

[0042] Lithium salt and organic solvent are configured into an electrolyte, and the electrolyte includes: LiPF with a concentration of 1.1M 6 , the solvent is a mixed organic solvent of ethylene carbonate (EC) and diethyl carbonate (DEC). The in-situ solution includes electrolyte, copolymerization precursor and a small amount of initiator. According to the mass ratio: the electrolyte solution: acrylamide (AM) is 8:2, and the content of the initiator azobisbutyronitrile (AIBN) is 0.8% of the monomer content. The above substances are prepared into a uniform and clear mixed solution for later use.

Embodiment 3

[0044] Except that the preparation of the mixed solution is different from that in Example 1, other preparation processes are the same as in Example 1.

[0045] Mixture preparation:

[0046] Lithium salt and organic solvent are configured into an electrolyte, and the electrolyte includes: LiPF with a concentration of 1.1M 6 , the solvent is a mixed organic solvent of ethylene carbonate (EC) and diethyl carbonate (DEC). The in-situ solution includes electrolyte, copolymerization precursor and a small amount of initiator. According to the mass ratio: electrolyte: acrylamide (AM) is 7:3, and the content of the initiator azobisbutyronitrile (AIBN) is 1% of the monomer content. The above substances are prepared into a uniform and clear mixed solution for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com