Nitrogen-doped carbon quantum dot/metal organic framework material MOF-5 photocatalyst as well as preparation method and application thereof

A metal-organic framework, MOF-5 technology, applied in the field of photocatalyst preparation, can solve problems such as poor stability, fast electron-hole recombination, and low conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

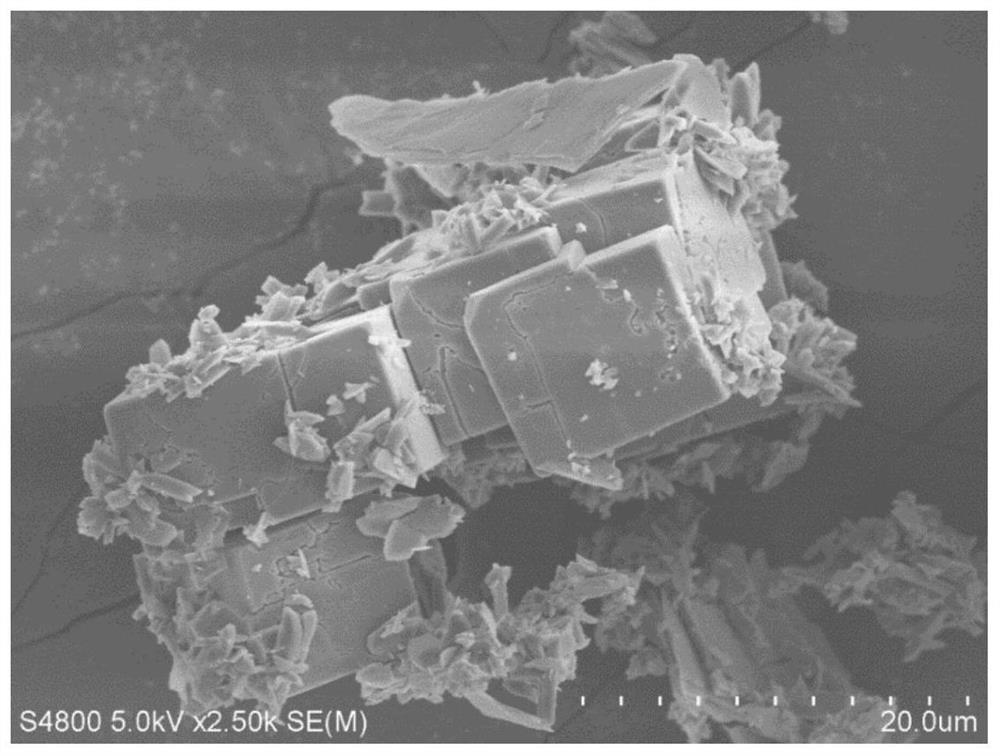

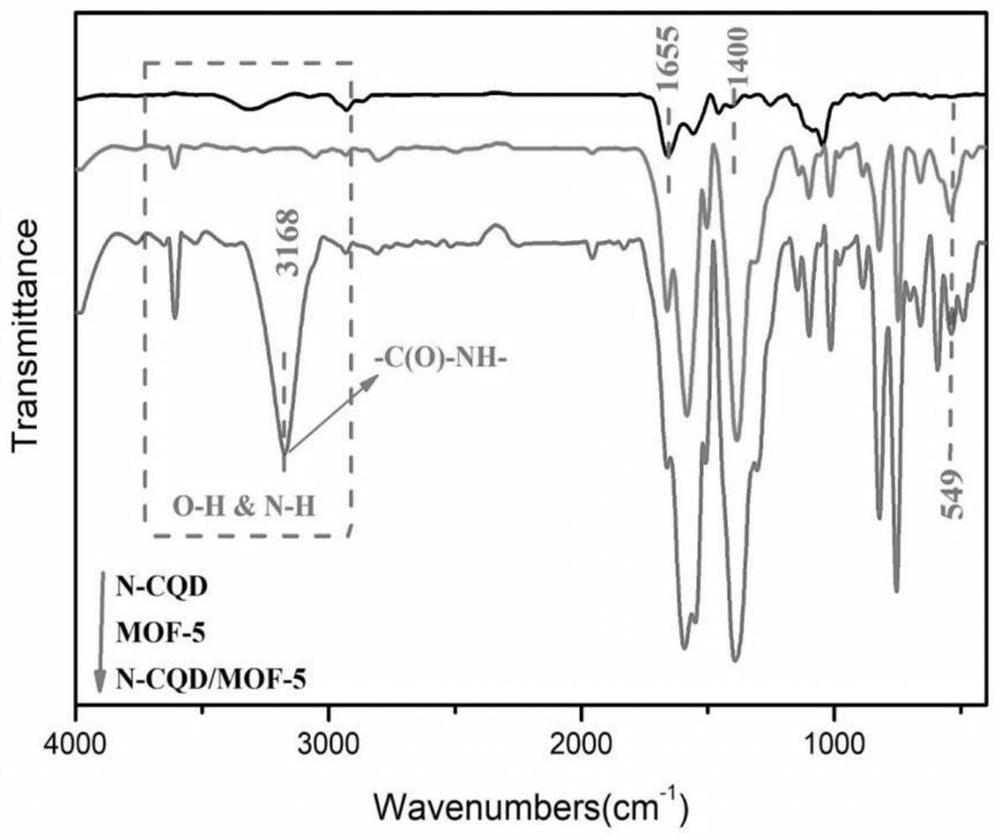

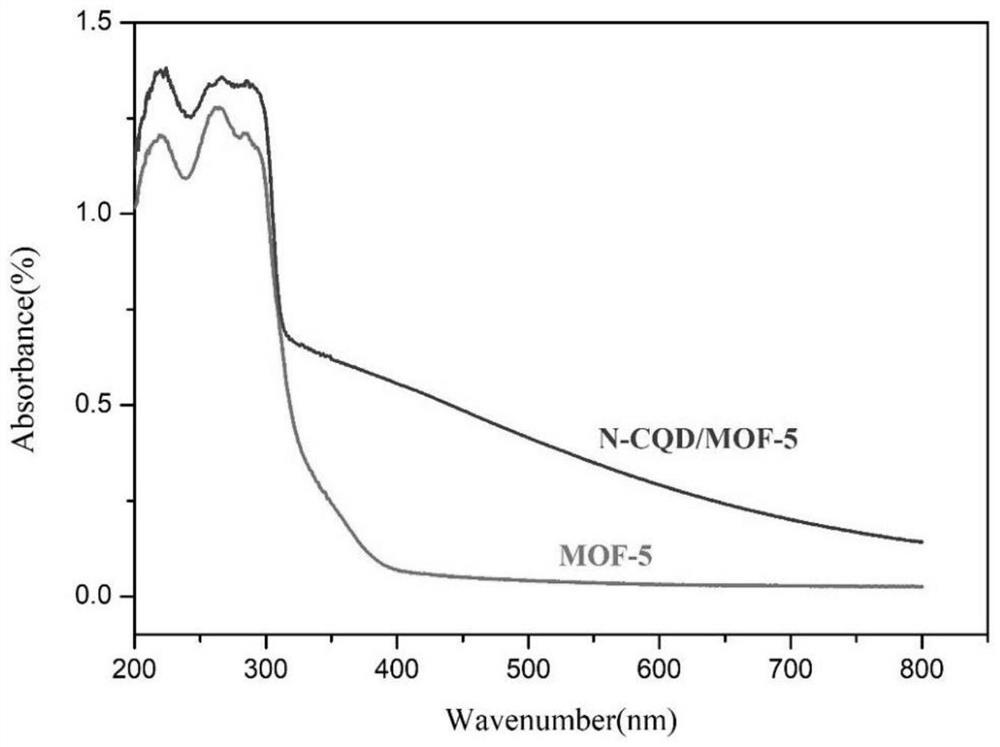

[0038] A preparation method of nitrogen-doped carbon quantum dot / metal organic framework material MOF-5 photocatalyst (N-CQD / MOF-5), comprising the following steps:

[0039] 1) Coconut shell treatment: remove the coconut meat from the waste coconut shell, dry it at 80°C, beat it into small pieces, and crush it to about 200 mesh with a pulverizer, put it in a sample bag to dry for later use;

[0040] 2) Weigh 1.0g of the processed coconut shell powder, dissolve it in 50ml of pure water, stir evenly, add 0.2 urea, and continue stirring until the urea is completely dissolved;

[0041] 3) Transfer the above solution to a polytetrafluoroethylene-lined reactor, react at 180°C for 18 hours, and after cooling to room temperature, take out the solution in the reactor, filter until the solution is clear, and perform dialysis with a 500 molecular weight dialysis bag for three days , change the water every 3 times, and freeze-dry to obtain solid nitrogen-doped carbon quantum dots;

[004...

Embodiment 2

[0045] A preparation method of nitrogen-doped carbon quantum dot / metal organic framework material MOF-5 photocatalyst (N-CQD / MOF-5), comprising the following steps:

[0046] 1) Coconut shell treatment: Remove the coconut meat from the waste coconut shell, dry it at 100°C, beat it into small pieces, and crush it to about 200 mesh with a pulverizer, put it in a sample bag to dry for later use;

[0047] 2) Weigh 1.0g of the processed coconut shell powder, dissolve it in 60ml of pure water, stir evenly, add 0.4 urea, and continue stirring until the urea is completely dissolved;

[0048] 3) Transfer the above solution to a polytetrafluoroethylene-lined reaction kettle, react at 180°C for 16 hours, and after cooling to room temperature, take out the solution in the reaction kettle, filter until the solution is clear, and perform dialysis with a 500 molecular weight dialysis bag for three days , change the water every 5 hours, and freeze-dry to obtain solid nitrogen-doped carbon quan...

Embodiment 3

[0052] 1) Coconut shell treatment: Remove the coconut meat from the waste coconut shell, dry it at 100°C, beat it into small pieces, and crush it to about 200 mesh with a pulverizer, put it in a sample bag to dry for later use;

[0053] 2) Weigh 1.0g of processed coconut shell powder, dissolve it in 60ml of pure water, stir evenly, add 0.6g of urea, and continue stirring until the urea is completely dissolved;

[0054] 3) Transfer the above solution to a polytetrafluoroethylene-lined reactor, react at 150°C for 14 hours, cool to room temperature, take out the solution in the reactor, filter until the solution is clear, and perform dialysis with a 500 molecular weight dialysis bag for three days , change the water every 5 hours, and freeze-dry to obtain solid nitrogen-doped carbon quantum dots;

[0055] 4) Weigh 0.8g of zinc nitrate hexahydrate, dissolve it in about 60ml of N'N-dimethylformamide (DMF), stir until completely dissolved, add 0.003g of solid nitrogen-doped carbon q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com