A polyaniline-based mof nanocomposite flexible supercapacitor and preparation method thereof

A nanocomposite material and supercapacitor technology, applied in the field of energy, can solve the problems of reducing specific capacity, increasing polyaniline charge-discharge cycle stability, and reducing specific surface area, so as to achieve good electrochemical characteristics and stability, and improve electrochemical performance. Cycling stability, effect of increasing charge transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

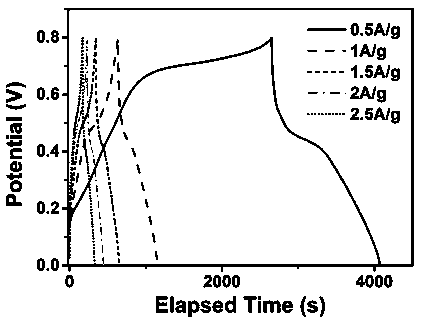

[0022] A preparation method of a polyaniline-based MOF nanocomposite flexible supercapacitor of the present invention comprises the following steps:

[0023] 1. PANI / MIL-101 nanocomposites were prepared by in-situ polymerization as electrode active materials;

[0024] The described PANI / MIL-101 adopts the in-situ redox rapid polymerization method, the aniline monomer concentration is 0.05-5mol / L, the MIL-101 accounts for 10-50% of the aniline monomer mass fraction, and the rapid reaction is carried out at room temperature for 30min. .

[0025] 2. Weigh the raw materials of PVDF, acetylene black and composite materials according to the mass ratio of 0.5~1:1:8~8.5, grind them evenly, add them in sequence, and ultrasonically disperse them in N-methyl-2-pyrrolidone to make the concentration 10mg / mL slurry, then coated on carbon fiber cloth to form electrodes;

[0026] 3. Preparation of flexible supercapacitors.

[0027] Specifically, the prepared two electrodes are immersed in ...

Embodiment 1

[0030] 1) Preparation of electrode material PANI / MIL-101: under the condition of vacuuming, firstly, 0.2mol / L aniline and MIL-101, which accounts for 10% of the mass fraction of aniline monomer, were mixed and adsorbed in a three-necked flask, and then aniline di The polymer was dissolved in a small amount of ethanol and added to a three-necked flask, followed by adding hydrochloric acid, stirring evenly, and sonicating for 10 minutes. At the same time, the amount of ammonium persulfate and aniline was weighed and dissolved in hydrochloric acid. Both were precooled for 20 minutes at the same time. The hydrochloric acid solution was quickly poured into the aniline solution, and the reaction was rapidly stirred for 30 min. The product was then purified and dried with absolute ethanol and deionized water.

[0031] 2) Preparation of electrodes: using an area of 1 × 2 cm 2 The hydrophilic carbon cloth is used as the current collector, and the electrode material is made of slurry...

Embodiment 2

[0034]1) Preparation of electrode material PANI / MIL-101: Under the condition of vacuuming, 0.2mol / L aniline and MIL-101, which accounts for 20% of the mass fraction of aniline monomer, were mixed and adsorbed in a three-necked flask, and then aniline di The polymer was dissolved in a small amount of ethanol and added to a three-necked flask, followed by adding hydrochloric acid, stirring evenly, and sonicating for 10 minutes. At the same time, the amount of ammonium persulfate and aniline was weighed and dissolved in hydrochloric acid. Both were precooled for 20 minutes at the same time. The hydrochloric acid solution was quickly poured into the aniline solution, and the reaction was rapidly stirred for 30 min. The product was then purified and dried with absolute ethanol and deionized water.

[0035] 2) Preparation of electrodes: using an area of 1 × 2 cm 2 The hydrophilic carbon cloth is used as the current collector, and the electrode material is made of slurry and coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com