Mg/Ti co-doped Li3PO4 coated high-nickel ternary positive electrode material and preparation method thereof

A positive electrode material and co-doping technology, applied in chemical instruments and methods, nickel compounds, electrical components, etc., can solve safety problems, hinder practical applications, poor thermal stability and chemical stability and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

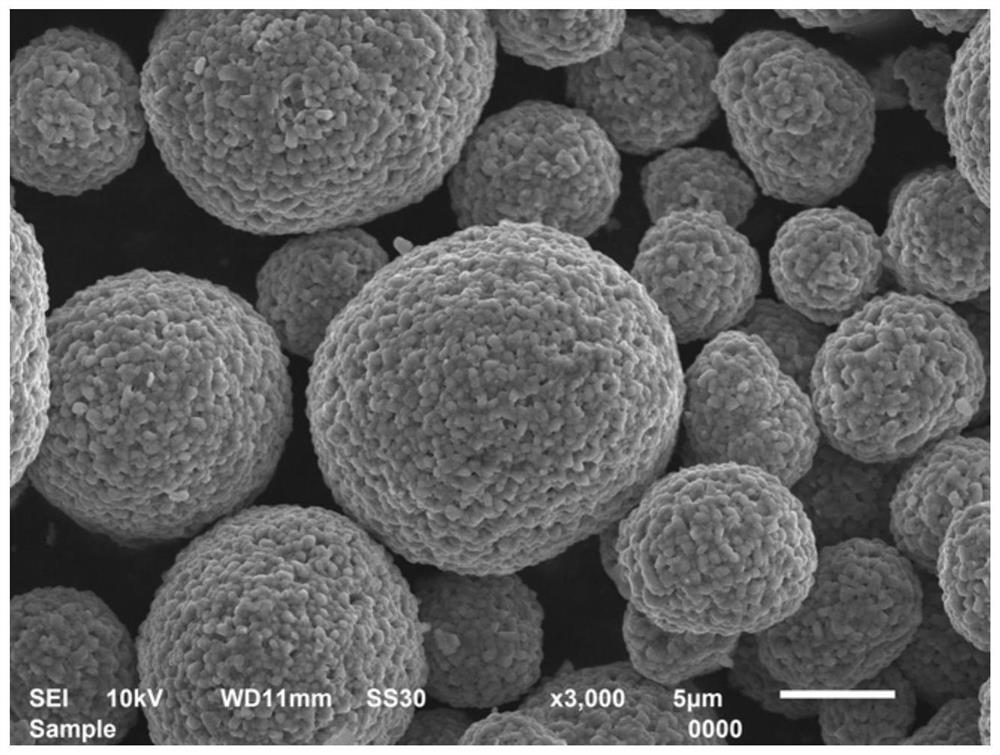

Image

Examples

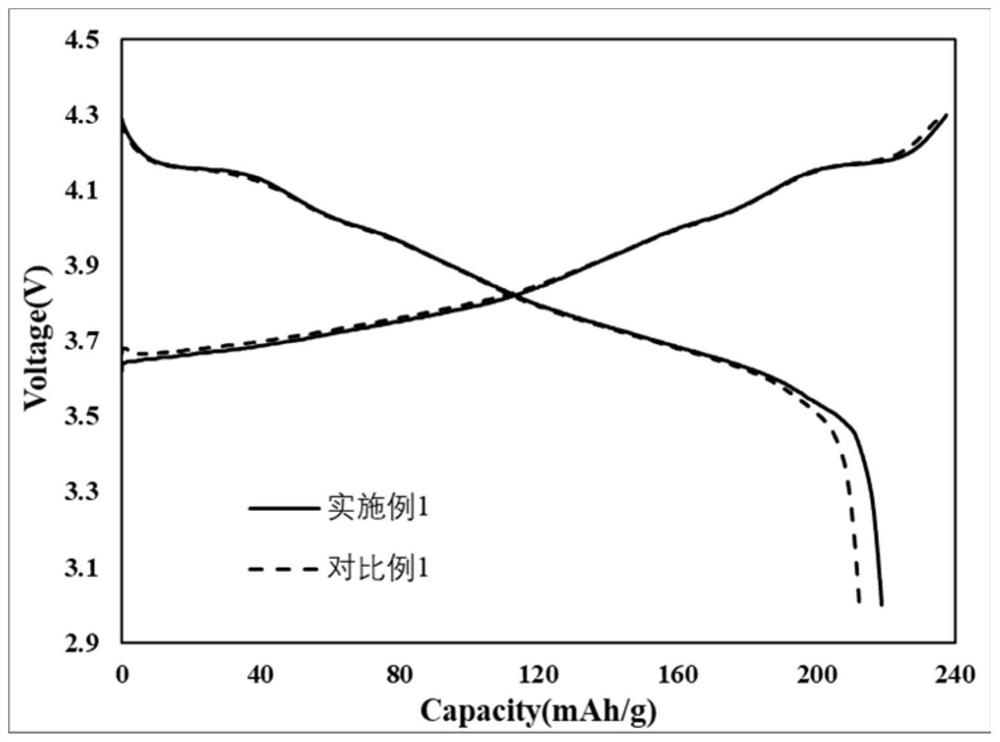

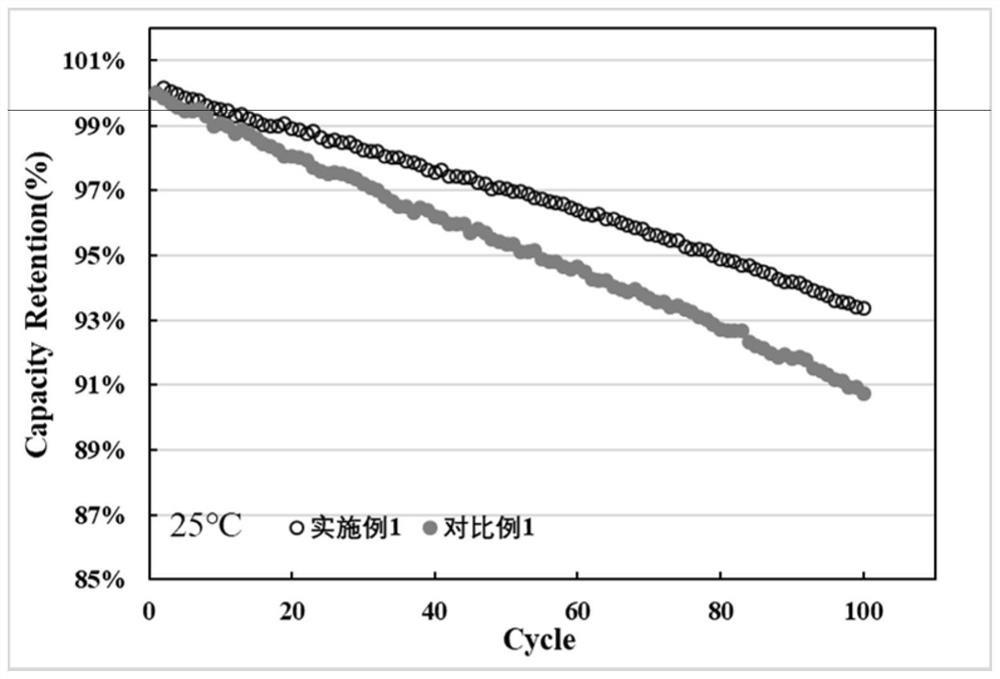

Embodiment 1

[0036] (1), weigh a certain amount of Ni 0.88 co 0.08 mn 0.04 (OH) 2 High-nickel ternary precursor, lithium hydroxide, magnesium carbonate and titanium oxide, wherein the input amount of lithium hydroxide is 1.04:1 according to the molar ratio of lithium and nickel-cobalt-manganese system, and the doping amount of magnesium carbonate and titanium oxide is 0.02% respectively and 0.05%. Add the premixed mixture into the high-speed mixer and mix well to obtain the mixture;

[0037] (2) The obtained mixture is sintered at a low temperature in an oxygen atmosphere, the sintering temperature is 500°C, and the sintering time in the main temperature zone is 8h; then the temperature is raised to 800°C, kept for 10h, and the Mg / Ti doping is obtained after natural cooling Matrix material.

[0038] (3) Fully premix the primary sintered material with a mass ratio of 3% lithium phosphate, add it into the mixer, use a mixing speed of 600rpm, and mix for 3h; secondly sinter at 650°C for ...

Embodiment 2

[0040] (1), weigh a certain amount of Ni 0.83 co 0.10 mn 0.07 (OH) 2 The ternary precursor, lithium hydroxide, 0.04% doped magnesium carbonate and titanium oxide, wherein the input amount of lithium hydroxide is 1.04:1 according to the molar ratio of lithium and nickel-cobalt-manganese system, are added to the high-speed mixer and mixed thoroughly Homogeneously, a mixture is obtained;

[0041] (2) The obtained mixture was first sintered at low temperature, and sintered at 500° C. for 8 hours in an oxygen atmosphere; then the temperature was raised to 850° C., kept for 10 hours, and the Mg / Ti doped matrix material was obtained after natural cooling.

[0042] (3), fully premix the primary sintered product obtained in step (2) with lithium phosphate, wherein the mass ratio of lithium phosphate is 2%, the mixing speed is 600rpm, and the mixing time is 3h; the secondary sintering is 6h at 650°C under an oxygen atmosphere, Mg / Ti double-doped Li obtained after natural cooling 3 PO...

Embodiment 3

[0044] (1), weigh a certain amount of Ni 0.83 co 0.10 mn 0.07 (OH) 2 High-nickel ternary precursor, lithium hydroxide, wherein the input amount of lithium hydroxide is 1.06:1 according to the molar ratio of lithium and nickel-cobalt-manganese system, and magnesium carbonate and titanium oxide with 0.05% doping amount are added to the high-speed mixer to fully Mix well to get a mixture;

[0045] (2) The obtained mixture was sintered at 500° C. for 8 hours in an oxygen atmosphere; then the temperature was raised to 870° C., kept for 10 hours, and the Mg / Ti doped matrix material was obtained after natural cooling.

[0046] (3) Fully mix the obtained primary sintered product with 3% mass ratio lithium phosphate, the mixing speed is 600rpm, and the mixing time is 3h; the secondary sintering is at 650°C for 6h under an oxygen atmosphere, and the Mg / Ti double-doped Li 3 PO 4 coated cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com