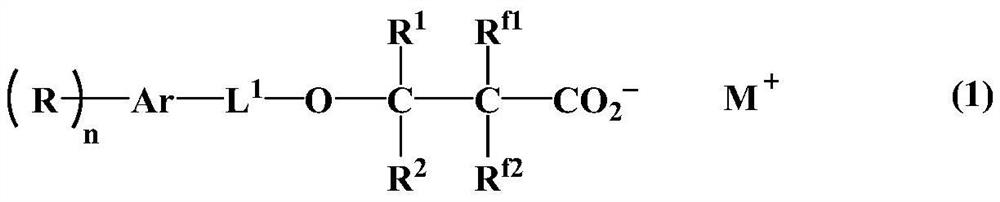

Onium salt compound, chemically amplified resist composition, and pattern forming method

A compound, onium salt technology, applied in the direction of organic chemistry, optics, photolithography process of pattern surface, etc., can solve the problems of inability to obtain photolithography performance and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

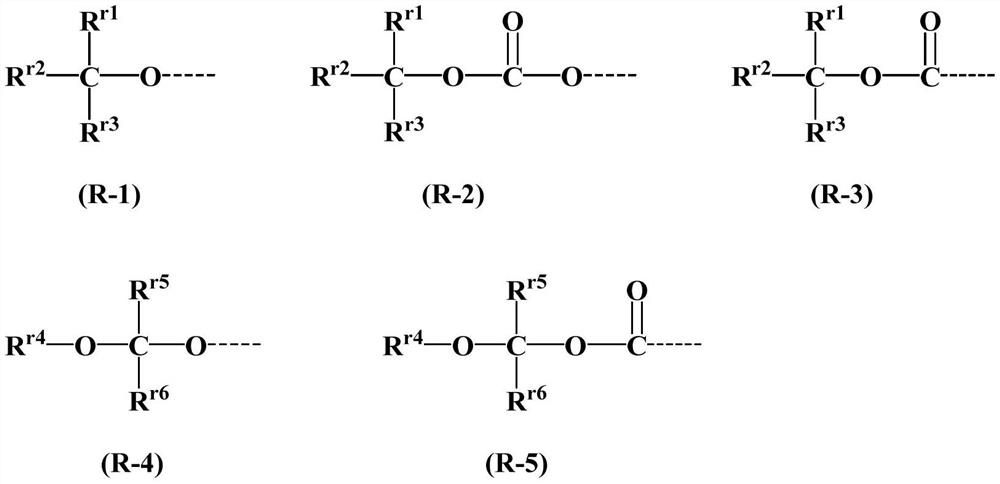

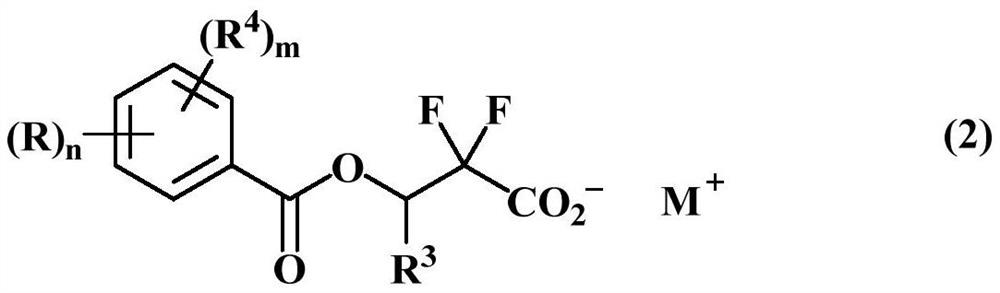

Method used

Image

Examples

Embodiment 1-1

[0530][Example 1-1] Synthesis of an acid diffusion inhibitor Q-1

[0531](1) Synthesis of Compound SM-2

[0532][化 116]

[0533]

[0534]354.7 g of Compound SM-1 was mixed with 437.2 g of tert-butoxybenzoic acid, N, N-dimethylaminopyridine 66.5 g and methylene chloride 3,400 g, add N- (3-dimethylaminopropyl) The group) -N'-ethyl carbon diimine hydrochloride was 450.9 g for stirring at room temperature for 21 hours. use19F-NMR confirms that 5% by mass Nahco is added after completion of the reaction3The aqueous solution was 1,600 g and stirred, and the reaction was quenched. After separating the organic layer, add 1,600 g of pure water and 400 g of saturated saline, and wash it once. After the obtained organic layer was concentrated under reduced pressure, hexane 2,000 g was added to dissolve, and the organic layer was washed with pure water 1,000 g, 5% by weight of 1,000 g and pure water 1,000 g. The obtained organic layers were concentrated under reduced pressure, and the crude product was evap...

Embodiment 1-2

[0549][Example 1-2] Synthesis of an acid diffusion inhibitor Q-22

[0550](1) Synthesis of Compound SM-5

[0551]119]

[0552]

[0553]11.8 g of Compound SM-1, 14.8 g of Compound SM-4, N, N-dimethylaminopyridine 0.73 g and 70 g of dichloromethane were mixed, and N- (3-dimethylaminopropyl) was added. N'-ethyl carbon diimide hydrochloride was 13.8 g for stirring at room temperature for 60 hours. use19F-NMR confirmed that after the reaction was completed, 40 g of pure water was added and stirred, and the reaction was quenched. After separating the organic layer, washed 40 g of 2% by mass hydrochloric acid. Further, the organic layer was washed once at pure water 40g 40 g of a saturated aqueous solution of sodium hydrogencarbonate, washed once, and washed once in pure water, and washed with 40 g of saline. The obtained organic layer was added to the activated carbon 1.2 g and stirred for 60 hours, and the activated carbon was filtered, and the obtained filtrate was concentrated under reduced pressu...

Embodiment 1-3~1-22

[0568][Examples 1-3 ~ 1-22] Synthesis of acid diffusion inhibitors Q-2 ~ Q-21

[0569]Further, reference to the first 1-1 to 1-2, the following acid diffusion inhibitors Q-2 to Q-21 are synthesized.

[0570]122]

[0571]

[0572]123]

[0573]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com