Preparation method of porous orthorhombic-phase niobium pentoxide nano material

A technology of niobium pentoxide and nanomaterials, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc. Controllable preparation of flowers, difficult to control product morphology, poor repeatability and other problems, to achieve the effect of uniform morphology, low cost and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Add 0.1g of niobium pentachloride to 50mL of ethanol, sonicate evenly, slowly add sodium hydroxide dropwise to adjust the pH to 8.5, and solvent heat in the reaction kettle for 12h. The reaction product is washed by centrifugation, heated and dried under normal pressure to obtain white niobium pentoxide precursor powder.

[0035] (2) The obtained niobium pentoxide precursor was calcined in a muffle furnace at 600° C. for 5 hours to obtain porous nanoplatelet niobium pentoxide.

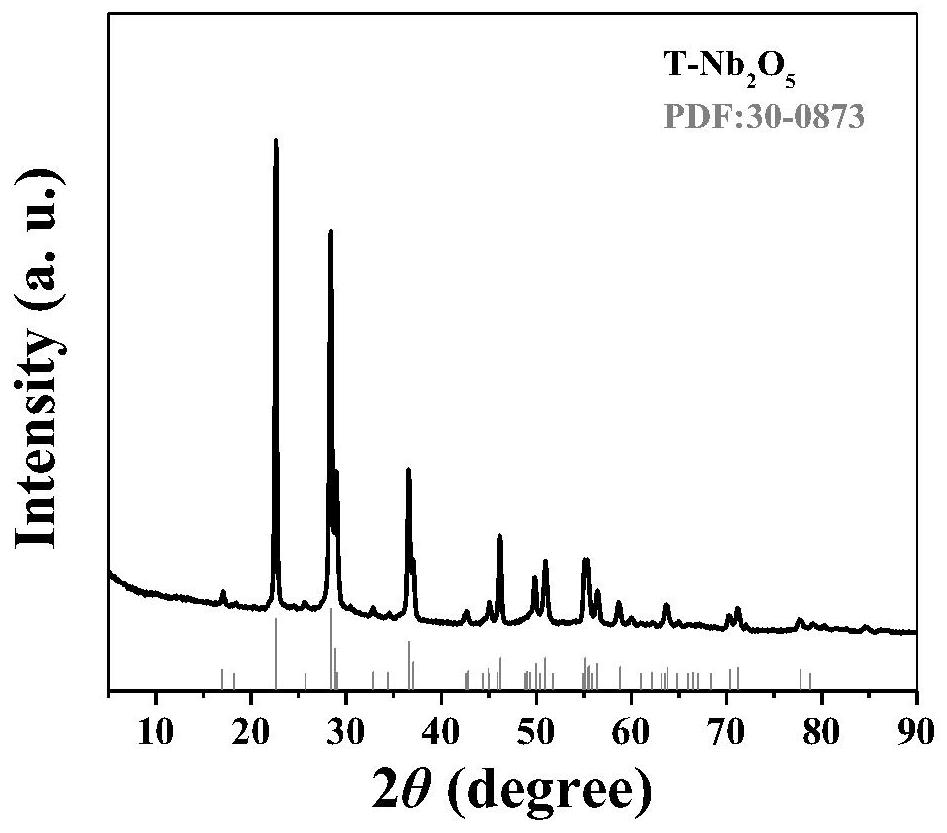

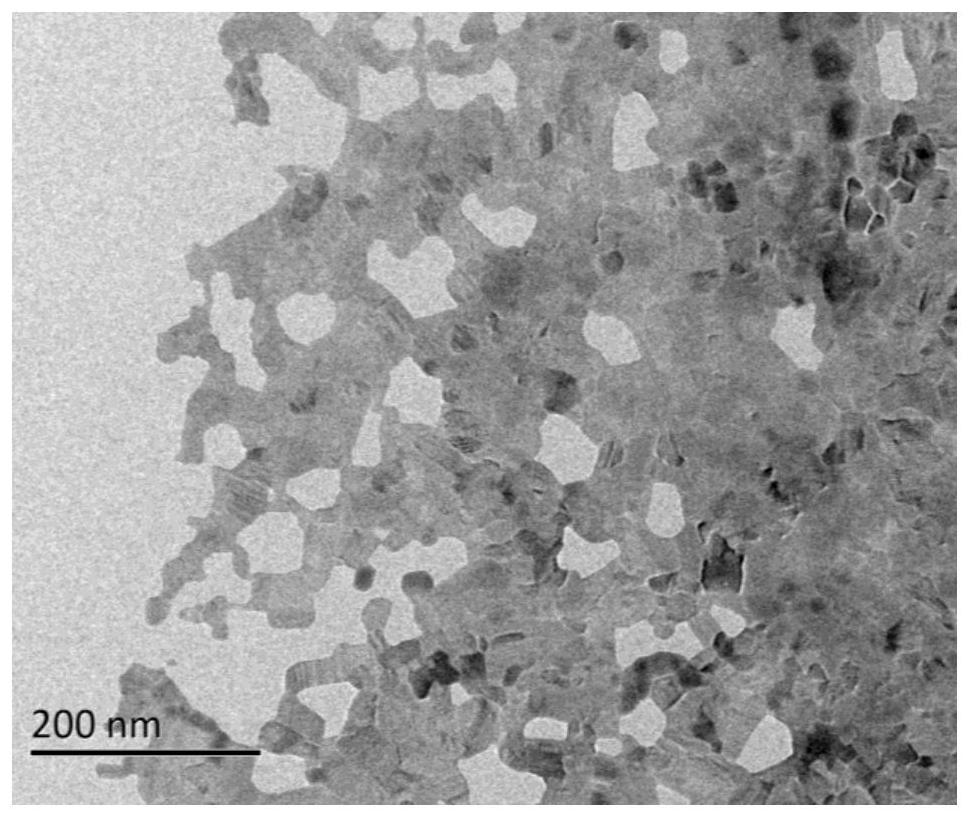

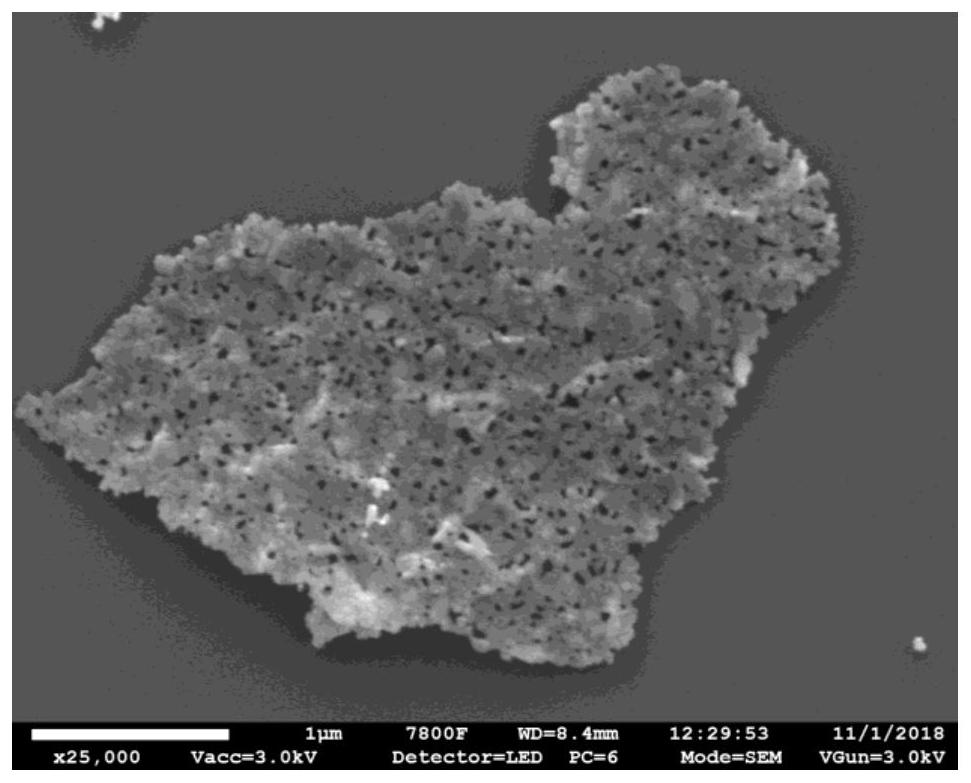

[0036] The XRD diffraction peak of the obtained niobium pentoxide belongs to PDF card: 30-0837, which is the orthorhombic phase of niobium pentoxide. The size of the nanosheet is about 1 μm-2 μm, the thickness is about 10 nm, and the pore size ranges from 10-80 nm. Lithium battery test results: when charging and discharging at 100mA / g, the specific capacity of the electrode material is as high as 190mAh / g.

Embodiment 2

[0038] (1) Add 0.15g of niobium oxalate into 80mL of water, shake evenly, slowly add ammonia water dropwise to adjust the pH to 9, and solvoheat in the reaction kettle for 20h. The reaction product was washed by suction filtration and freeze-dried to obtain white niobium pentoxide precursor powder.

[0039] (2) The obtained niobium pentoxide precursor was calcined in a muffle furnace at 650° C. for 3 hours to obtain porous nanosheet-shaped orthorhombic phase niobium pentoxide.

[0040] The obtained niobium pentoxide nano sheet has a size of about 1 μm-3 μm, a thickness of about 20 nm, and a pore diameter range of 50-200 nm. Lithium battery tests show that when charging and discharging at 500mA / g, the specific capacity of the electrode material can reach 170mAh / g.

Embodiment 3

[0042] (1) Add 0.2g of niobium ethanol to a mixed solvent of 100mL of ethanol and ethylene glycol (volume ratio: 1:1), stir evenly, slowly add potassium hydroxide dropwise to adjust the pH to 10, and solvoheat in the reaction kettle for 15h . The reaction product is washed by centrifugation, heated and dried in vacuum to obtain white niobium pentoxide precursor powder.

[0043] (2) The obtained niobium pentoxide precursor was calcined in a muffle furnace at 700° C. for 1.5 h to obtain porous nanoflower-shaped orthorhombic phase niobium pentoxide.

[0044]The obtained niobium pentoxide nanoflowers have a size of about 500nm-1.5μm, are self-assembled by porous nanosheets with a thickness of about 20nm, and have a pore size range of 20-100nm. Lithium battery test results: when charging and discharging at 200mA / g, the specific capacity of the electrode material can reach 185mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com