A kind of sharp biological titanium material and preparation method thereof

A bio-titanium, anodizing technology, applied in nanotechnology for materials and surface science, electrolytic coatings, coatings, etc., can solve the problems such as the need for further improvement of antibacterial properties, uncontrollable nanotube array structure, etc. The effect of ideal arrangement, high order and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment provides a method for preparing a sharp-shaped biological titanium material, comprising the following steps:

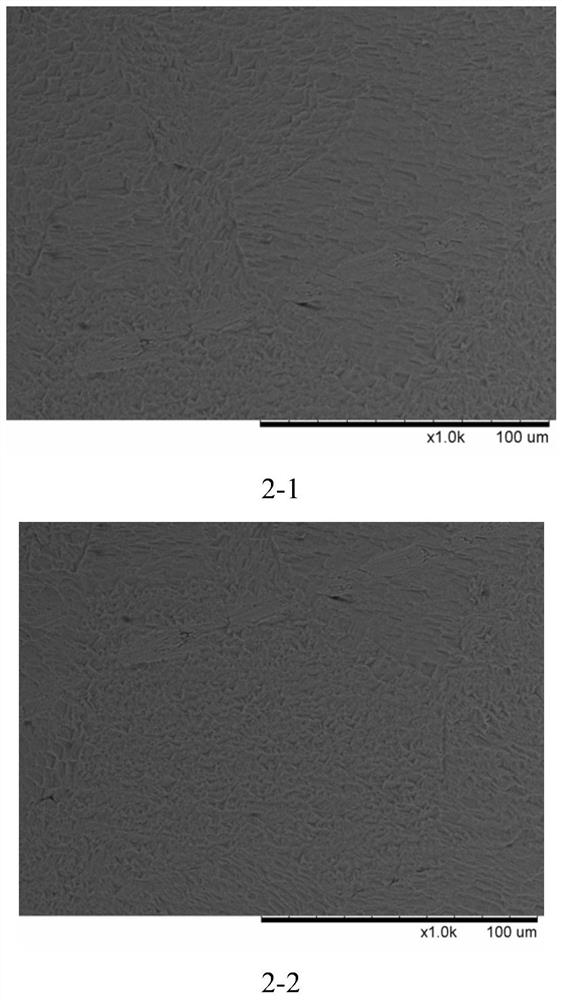

[0044] The titanium metal is placed in an electrolyte for anodization, and the electrolyte includes phosphoric acid, sodium gluconate and additives (additives include sodium phosphate and sodium molybdate with a mass ratio of 3:7) of 0.75:1:0.8. The mixture, wherein the mass concentration of phosphoric acid is 100mg / L, the mass concentration of sodium gluconate is 200g / L, the concentration of sodium phosphate is 0.024g / L, the concentration of sodium molybdate is 0.056g / L, and the voltage of one anodic oxidation is 50V, the time is 15min, a large number of titanium dioxide nanotubes are generated, the titanium metal is ultrasonically cleaned, and then the titanium metal is treated with equal voltage and reverse polarity three times. The time interval between the two adjacent equal voltage and reverse polarity treatments is 1s. The voltage ...

Embodiment 2

[0048] The present embodiment provides a preparation method of a sharp-shaped biological titanium material, comprising the following steps:

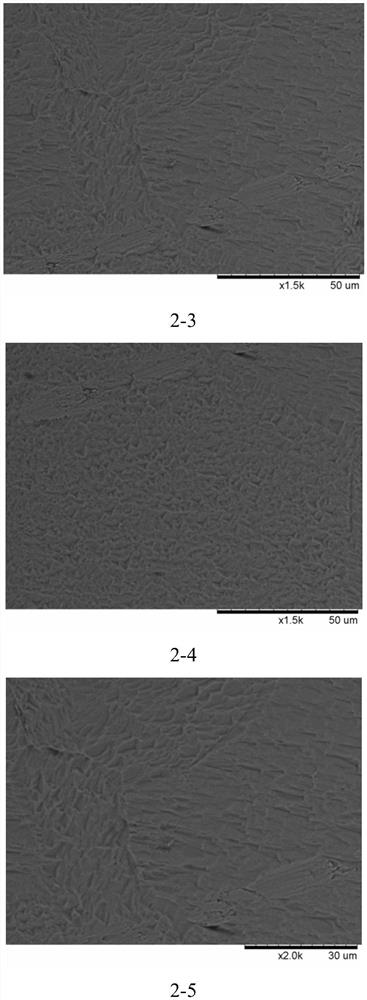

[0049] The titanium metal is placed in an electrolyte for anodization, and the electrolyte is a mixture of phosphoric acid, sodium gluconate and additives (additives include sodium phosphate and sodium molybdate with a mass ratio of 3:7) in a mass ratio of 0.75:1:0.8. The mixture, wherein the mass concentration of phosphoric acid is 100mg / L, the mass concentration of sodium gluconate is 200g / L, the concentration of sodium phosphate is 0.024g / L, the concentration of sodium molybdate is 0.056g / L, and the voltage of one anodic oxidation is 30V, the time is 15min, a large number of titanium dioxide nanotubes are generated, the titanium metal is ultrasonically cleaned, and then the voltage is adjusted to 50V, and the titanium metal is subjected to 3 times of equal voltage and reverse polarity treatment, and the time interval of two adjacent eq...

Embodiment 3

[0052] The present embodiment provides a preparation method of a sharp-shaped biological titanium material, comprising the following steps:

[0053] The titanium metal is placed in an electrolyte for anodization, and the electrolyte is a mixture of phosphoric acid, sodium gluconate and additives (additives include sodium phosphate and sodium molybdate with a mass ratio of 3:7) in a mass ratio of 0.75:1:0.8. The mixture, wherein the mass concentration of phosphoric acid is 100mg / L, the mass concentration of sodium gluconate is 200g / L, the concentration of sodium phosphate is 0.024g / L, the concentration of sodium molybdate is 0.056g / L, and the voltage of one anodic oxidation is 10V, the time is 15min, a large number of titanium dioxide nanotubes are generated, the titanium metal is ultrasonically cleaned, and then the voltage is adjusted to 51V, and the titanium metal is subjected to 3 times of equal voltage and reverse polarity treatment, and the time interval of two adjacent eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com