Preparation method of vanadium trioxide and nitrogen-doped porous carbon composite negative electrode material

A technology of nitrogen-doped porous carbon and vanadium trioxide, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of poor product cycle stability, unfavorable large-scale production, complex synthesis methods, etc., and achieve excellent cycle Stability and rate performance, excellent rate performance, strong interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

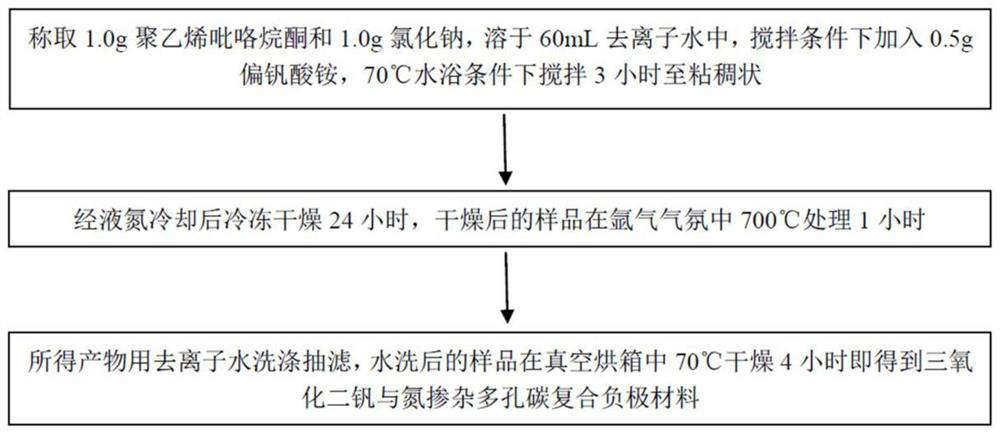

[0036] Such as figure 1 As shown, the preparation method of vanadium trioxide and nitrogen-doped porous carbon composite negative electrode material provided by the embodiment of the present invention includes the following steps:

[0037] Step 1: Weigh 1.0g of polyvinylpyrrolidone and 1.0g of sodium chloride, dissolve them in 60mL of deionized water, add 0.5g of ammonium metavanadate under stirring conditions, and stir under 70°C water bath conditions for 3 hours until viscous;

[0038] Step 2: freeze-dry and dry for 24 hours after cooling with liquid nitrogen, and treat the dried sample at 700°C for 1 hour in an argon atmosphere;

[0039] Step 3: The obtained product is washed with deionized water and filtered, and the washed sample is dried in a vacuum oven at 70° C. for 4 hours to obtain a composite negative electrode material of vanadium trioxide and nitrogen-doped porous carbon.

[0040] The composite negative electrode material of vanadium trioxide and nitrogen-doped p...

Embodiment 1

[0054] Weigh 1.0g of polyvinylpyrrolidone and 1.0g of sodium chloride, dissolve them in 60mL of deionized water, add 0.5g of ammonium metavanadate under stirring conditions, stir for 3 hours in a water bath at 70°C until viscous, and cool with liquid nitrogen Freeze-dried for 24 hours, the dried sample was treated in an argon atmosphere at 700°C for 1 hour, the obtained product was washed with deionized water and suction filtered, and the washed sample was dried in a vacuum oven at 70°C for 4 hours to obtain the trioxide Divanadium and nitrogen-doped porous carbon composite negative electrode material.

[0055] Implementation effect: the V prepared in this embodiment 2 o 3 Assembled with nitrogen-doped porous carbon composite anode materials to form a battery for charge and discharge tests, Figure 6 c is the cycle performance diagram of the assembled lithium-ion battery at a current density of 100mA / g and a voltage range of 3-0.01V. It can be seen that the first discharge ...

Embodiment 2

[0057] Weigh 1.0g of polyvinylpyrrolidone, dissolve it in 60mL of deionized water, add 0.5g of ammonium metavanadate under stirring conditions, stir in a water bath at 70°C for 3 hours until viscous, freeze-dry for 24 hours after cooling with liquid nitrogen, and dry The finished sample was treated in an argon atmosphere at 700°C for 1 hour, the obtained product was washed with deionized water and suction filtered, and the washed sample was dried in a vacuum oven at 70°C for 4 hours to obtain the vanadium trioxide doped with nitrogen Carbon composite anode materials. .

[0058] Implementation effect: the vanadium trioxide and nitrogen-doped carbon composite negative electrode material prepared in this example were assembled into a battery for charge and discharge test, and the charge and discharge test was carried out at a current density of 100mA / g, and its initial discharge capacity was 544mAh / g, the discharge capacity is maintained at 283mAh / g after 60 cycles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com