Method for constructing in-vitro tissue engineering cartilage

A technology of tissue engineering and constructs, applied in the field of bionic scaffolds, can solve the problems of loss of cartilage phenotype, hypertrophy or calcification of chondrocytes, a large amount of fibrotic cartilage, etc., and achieve the effect of promoting phenotype maintenance and growth of chondrocytes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for constructing tissue engineered cartilage in vitro, the specific steps are:

[0035] (1) Preparation of cartilage biomimetic scaffold;

[0036] (1.1) Preparation of raw materials;

[0037] The average diameter is 130nm and the material is the nanofiber bundle of bacterial cellulose; The silk fibroin aqueous solution with the concentration of 6wt%; The H concentration of 490mM 2 o 2 Aqueous solution; HRP solution with a concentration of 1000U / ml (HRP is dissolved in PBS buffer to obtain);

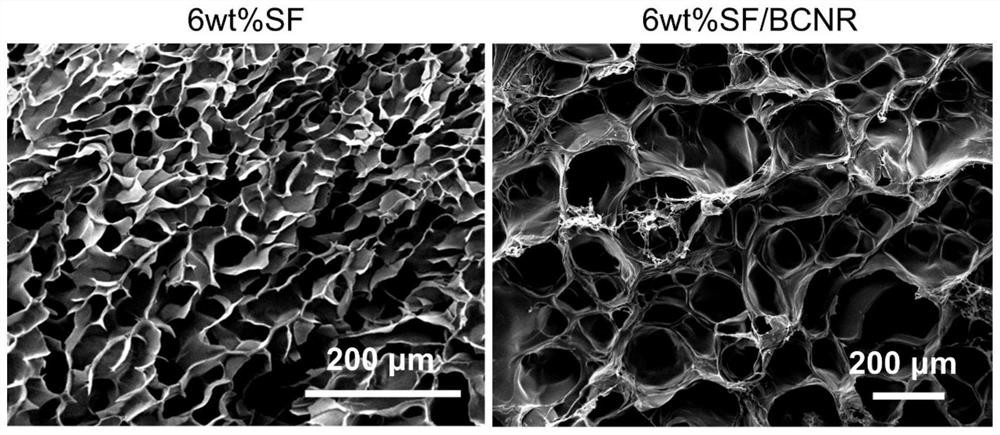

[0038] (1.2) Mix the nanofiber bundles and the silk fibroin aqueous solution to obtain a mixed solution; in the mixed solution, the weight ratio of the silk fibroin and the nanofiber bundles is 95:5;

[0039] (1.3) Add H to the mixture in sequence 2 o 2 Aqueous solution and HRP solution form a crosslinking system; H 2 o 2 The addition of the aqueous solution accounts for 5vol% of the volume content of the crosslinking system; the addition of the HRP solution account...

Embodiment 2

[0054] A method for constructing tissue engineered cartilage in vitro, the specific steps are:

[0055] (1) Preparation of cartilage biomimetic scaffold;

[0056] (1.1) Preparation of raw materials;

[0057] Nanofiber bundles with an average diameter of 30nm and a material made of polyvinyl alcohol; a concentration of 5wt% elastin in water; a concentration of 490mM H 2 o 2 Aqueous solution; HRP solution with a concentration of 1000U / ml (HRP is dissolved in PBS buffer to obtain);

[0058] (1.2) Mix the nanofiber bundles with the elastin aqueous solution to obtain a mixed solution; in the mixed solution, the weight ratio of the elastin and the nanofiber bundles is 95:5;

[0059] (1.3) Add H to the mixture in turn 2 o 2 Aqueous solution and HRP solution form a crosslinking system; H 2 o 2 The addition of the aqueous solution accounts for 3vol% of the volume content of the crosslinking system; the addition of the HRP solution accounts for 4vol% of the volume content of the ...

Embodiment 3

[0069] A method for constructing tissue engineered cartilage in vitro, the specific steps are:

[0070] (1) Preparation of cartilage biomimetic scaffold;

[0071] (1.1) Preparation of raw materials;

[0072] Nanofiber bundles with an average diameter of 100nm and made of polylactic acid; a gelatin aqueous solution with a concentration of 12wt%; a concentration of 490mM H 2 o 2 Aqueous solution; HRP solution with a concentration of 1000U / ml (HRP is dissolved in PBS buffer to obtain);

[0073] (1.2) Mix the nanofiber bundles with the gelatin aqueous solution to obtain a mixed solution; in the mixed solution, the weight ratio of the gelatin and the nanofiber bundles is 95:5;

[0074] (1.3) Add H to the mixture in sequence 2 o 2 Aqueous solution and HRP solution form a crosslinking system; H 2 o 2 The addition of the aqueous solution accounts for 6vol% of the volume content of the crosslinking system; the addition of the HRP solution accounts for 5vol% of the volume content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com