A kind of solid-phase microextraction probe and preparation method thereof

An extraction and stainless steel wire technology, applied in the field of analytical chemistry, can solve the problems of low preparation efficiency, cumbersome process, and long time, and achieve the effect of fast and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

(4) The stainless steel wire prepared by step (2) is immersed in the solution of step (3), then pulled out and smoothly put into the UV cross section.

The modified graphene-polysiloxane coating was synthesized by in-situ photopolymerization at 365 nm wavelength for 5 min in a tandem instrument; ethanol was used

Wash the coating and place in the GC inlet at 250 °C N

2

Dry under atmosphere for 12 h.

Table 1 alkenyl modified graphene-nanometer siloxane polymer coating component content table

[0034]

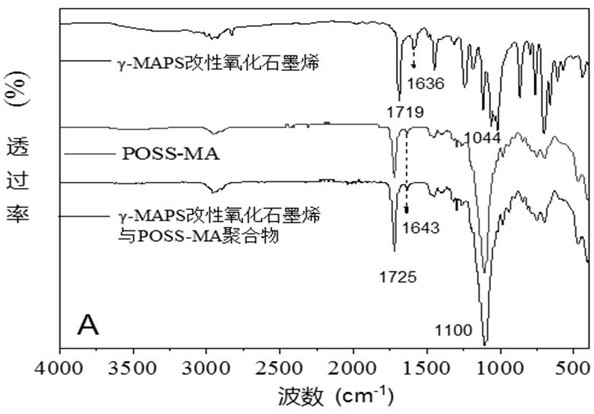

γ-MAPS@GO: methacryloxypropyltrimethoxysilane-modified graphene oxide

POSS-MA: monomer methyl methacrylate cage silsesquioxane

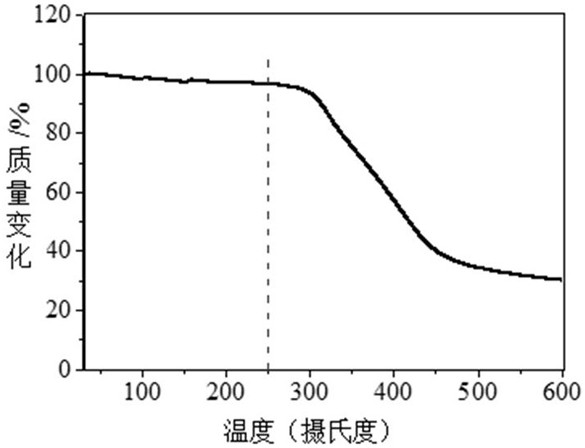

Taking table 1 formula B as an example, POSS / γ-MAPS@GO solid phase microextraction coating has been characterized:

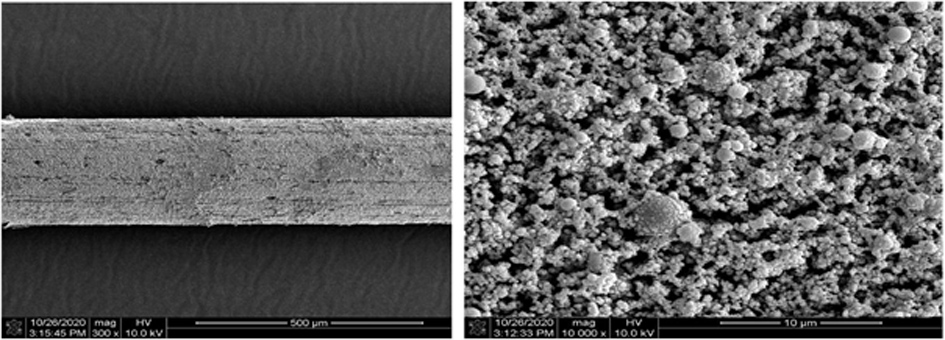

[0038] The polymeric coating is uniformly covered on the stainless steel fiber surface, and the polymeric clusters are relatively uniform (Fig. 1); the POSS / γ-

Embodiment 2

For example, when γ-MAPS@GO:POSS = 10.9: 14.5, a larger amount of hydrophilic γ-MAPS@GO nanosheets was added, the theoretical

The hydrophobicity and mechanical properties of the obtained polymers were reduced, and the adsorption performance to PCMs was reduced.

[0042] with commercial Carboxen / polydimethylsiloxane (CAR / PDMS), polydimethylsiloxane (PDMS) and polydimethylsiloxane

Siloxane / divinylbenzene (PDMS / DVB) comparison (Figure 6 and Table 2), for Sally Musk, Sandalwood Musk, Truss, Galore

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com