A kind of quaternary ammonium salt polysulfone/polyvinyl alcohol composite hydrogel, preparation method and application

A technology of composite hydrogel and polyvinyl alcohol, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, aerosol delivery, etc. Difficult to remove and other problems, to achieve the effect of good adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method of quaternary ammonium polysulfone / polyvinyl alcohol composite hydrogel, comprising the following steps:

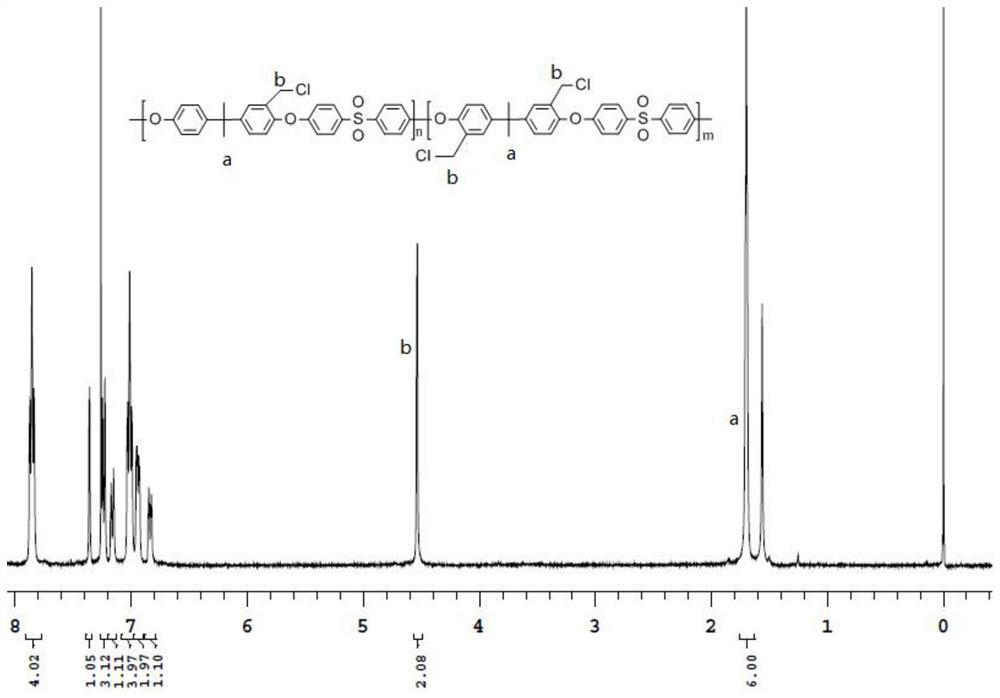

[0039] (1) Dissolve 10g of polysulfone in 500mL of anhydrous chloroform at 50°C, N 2 Under protection, 9g of paraformaldehyde, 50mL of trimethylchlorosilane, and 1.6g of anhydrous tin tetrachloride were sequentially added under stirring. During the reaction, nuclear magnetic detection followed the reaction. When the degree of chloromethylation substitution was greater than 1.0, see figure 1 Said, the degree of substitution is calculated according to formula (I), the reaction solution is poured into a large amount of ethanol, precipitated, filtered and dried; the prepared chloromethylated polysulfone is put into 100mL of 10wt% trimethylamine aqueous solution , stir overnight to obtain water-soluble quaternary ammonium polysulfone, remove most of the trimethylamine under reduced pressure, and then dialyze through a dialysis bag with a molecular w...

Embodiment 2

[0045] A preparation method of quaternary ammonium polysulfone / polyvinyl alcohol composite hydrogel, comprising the following steps:

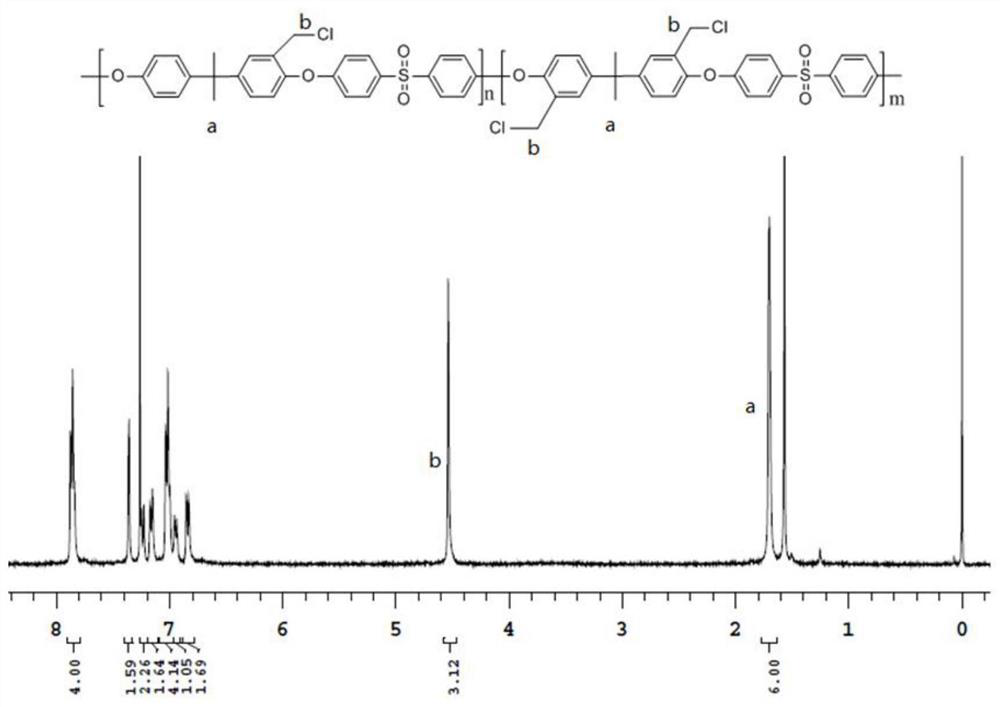

[0046] (1) Dissolve 10g of polysulfone in 500mL of anhydrous chloroform at 50°C, N 2 Under protection, 9g of paraformaldehyde, 50mL of trimethylchlorosilane, and 1.6g of anhydrous tin tetrachloride were sequentially added under stirring. During the reaction, nuclear magnetic detection followed the reaction. When the degree of chloromethylation was greater than 1.5, see figure 2 As shown, the reaction solution was poured into a large amount of ethanol, precipitated, filtered and dried; the prepared chloromethylated polysulfone was put into 100ml of 15wt% trimethylamine aqueous solution, and stirred overnight to obtain a water-soluble quaternary ammonium polysulfone Sulfone, remove most of the trimethylamine under reduced pressure, and then dialyze through a dialysis bag with a molecular weight cut-off of 2000Da to remove the residual trimethyla...

Embodiment 3

[0052] A preparation method of quaternary ammonium polysulfone / polyvinyl alcohol composite hydrogel, comprising the following steps:

[0053] (1) Dissolve 10g of polysulfone in 500mL of anhydrous chloroform at 50°C, N 2 Under protection, 9g of paraformaldehyde, 50mL of trimethylchlorosilane, and 1.5g of anhydrous tin tetrachloride were sequentially added under stirring. During the reaction, nuclear magnetic detection was used to track the reaction. When the degree of chloromethylation substitution was greater than 1.5, the reaction liquid Pour into a large amount of ethanol, precipitate out, filter and dry; put the prepared chloromethylated polysulfone into 100ml 13wt% trimethylamine aqueous solution, stir overnight to obtain water-soluble quaternary ammonium polysulfone, remove under reduced pressure Most of the trimethylamine is dialyzed to remove the residual trimethylamine through a dialysis bag with a molecular weight cut-off of 3000Da. The dialysis time is 24 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com